Some varieties of 3D-printed objects can now “feel," using a new technique that builds sensors directly into their materials. This research could lead to novel interactive devices such as intelligent furniture, a new study finds.

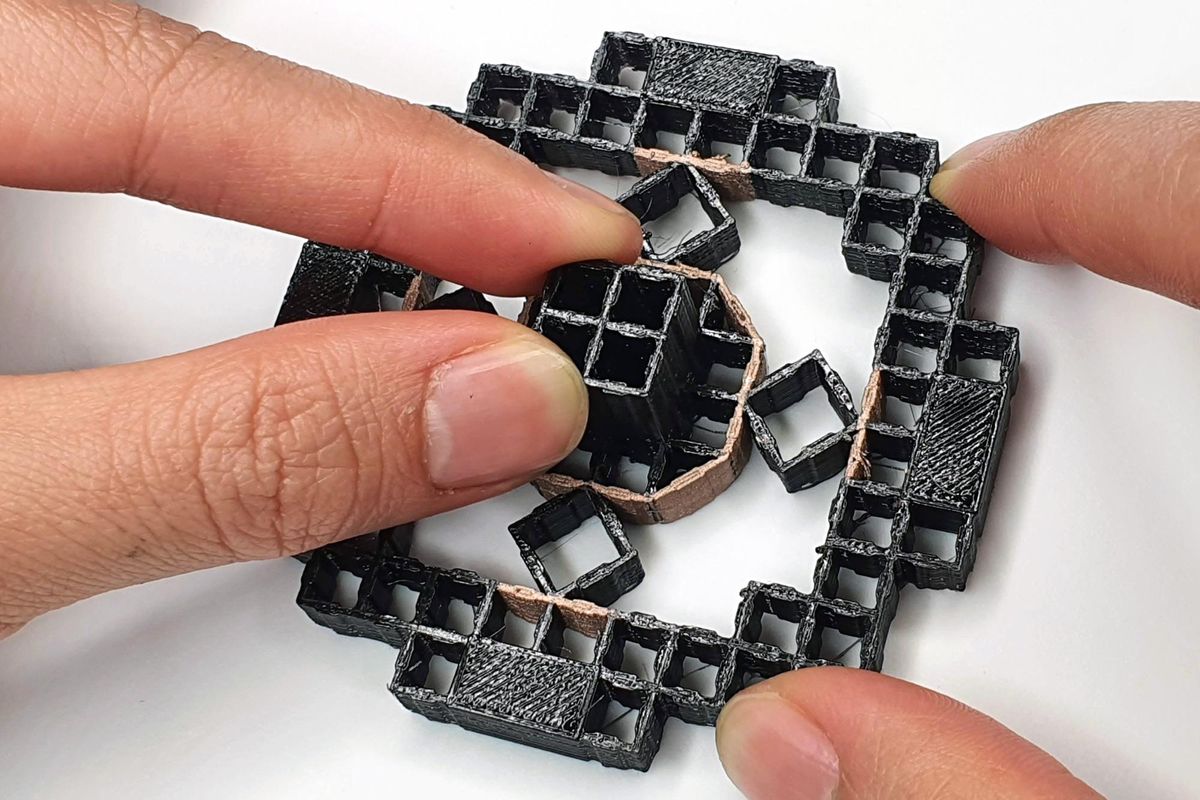

The new technique 3D-prints objects made from metamaterials—substances made of grids of repeating cells. When force is applied to a flexible metamaterial, some of their cells may stretch or compress. Electrodes incorporated within these structures can detect the magnitude and direction of these changes in shape, as well as rotation and acceleration.

In the new study, researchers manufactured objects made of flexible plastic and electrically conductive filaments. These had cells as small as 5 millimeters wide.

Each cell had two opposing walls made of conductive filament and nonconductive plastic, with the conductive walls serving as electrodes. Forces applied onto the objects change the distance and overlapping area between the opposing electrodes, generating electric signals that revealed details about the applied forces. In this manner, this new technique can "seamlessly and unobtrusively integrate sensing into the printed objects," says study co-author Jun Gong, a research scientist at Apple.

The researchers suggest these metamaterials could help designers quickly create and tweak flexible input devices for a computer. For instance, they created a music controller using these metamaterials that was designed to conform to a person's hand. When a user squeezes one of the flexible buttons, the resulting electric signals help control a digital synthesizer.

The scientists also fabricated a metamaterial joystick to play a game of Pac-Man. By understanding how people apply forces onto this joystick, a designer could prototype unique handle shapes and sizes for people with limited grip strength in certain directions.

"We can sense movement in any 3D-printed object," says study co-author Cedric Honnet, an embedded systems engineer at MIT. "From musical to game interfaces, the potential is really exciting."

The researchers also created 3D editing software, known as MetaSense, to help users build interactive devices using these metamaterials. It simulates how 3D-printed objects will deform when different forces are applied and calculates which cells change the most and are the best to use for electrodes.

"MetaSense allows designers to 3D print structures with built-in sensing capability in one go. This allows for super quick prototyping of devices, such as joysticks, for example, that can be customized for individuals with different accessibility needs," says study co-author Olivia Seow, a creative machine learning engineer at MIT.

Embedding hundreds or thousands of sensor cells into an object could help enable high-resolution, real-time analysis of how users interact with it, Gong says. For instance, a smart chair made with such metamaterials could detect a user's body and then switch on the light or TV, or collect data for later analysis such as detecting and correcting body posture. These metamaterials may also find use in wearable applications, Honnet says.

The scientists will detail their findings in October at the Association for Computing Machinery Symposium on User Interface Software and Technology.

Charles Q. Choi is a science reporter who contributes regularly to IEEE Spectrum. He has written for Scientific American, The New York Times, Wired, and Science, among others.