3-D printing has turned prototyping from something that takes days or weeks into something that takes hours. This is great, if the prototype that you end up with does what you want it to do, which it probably won’t, if you’re concerned with interactivity. You can certainly take a dremel to whatever you’ve just printed and try and stuff some sensors into it, but that sounds like a lot of work, which is why researchers at Queen’s University (the one in Ontario) have combined conductive filament with a dual-extruder 3-D printer to create a way to print objects with sensors in them all in one shot.

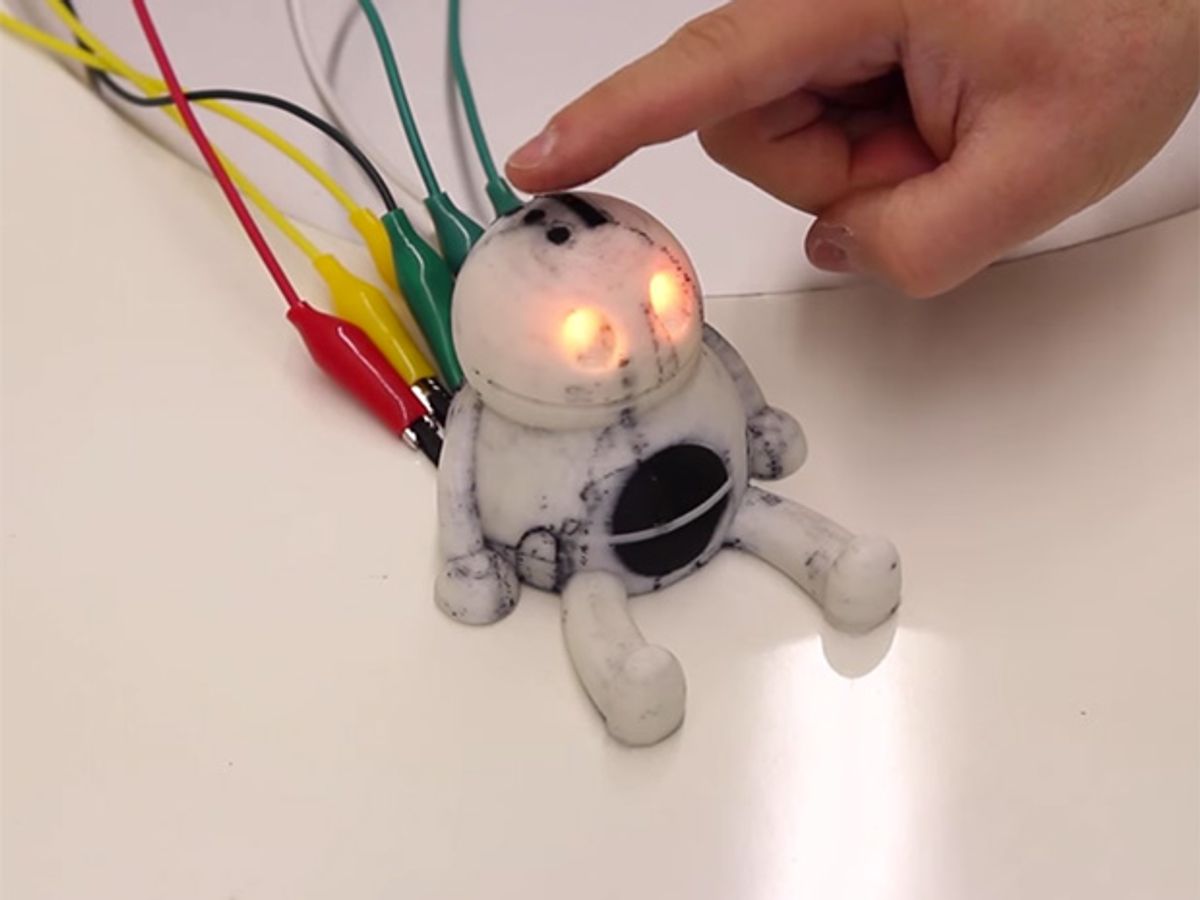

PrintPut can handle all kinds of interactive elements, including buttons, pressure sensors, sliders, touchpads, and flex sensors. These elements can be integrated into just about any surface, not just flat ones, which opens up tons of creative options to designers, and said designers can leave most of the tricky CAD stuff up to software scripts. All you have to do is design a CAD model just like you would normally and then use a plugin to define points and curves for the interactive areas. The software then figures out how to integrate all of the conductive channels, and you end up with two interlocking 3-D models: your original CAD design with all of the conductive areas hollowed out of it and conductive pathways to fill those areas. Send it along to your dual-extruder 3-D printer, and then go get a latte, because you’re pretty much done. The final step, once your print is complete, is to attach alligator clips to the 3-D–printed conductive terminals leading to each sensor, and then wire it all up with an Arduino or some other microcontroller.

Besides both capacitive and resistive buttons, sliders, and touchpads, a little extra cleverness will let you implement more complex sensors. For example, you can make an analog pressure sensor by printing two conductive pads with a gap in the middle, and then measure the decreasing resistance as one pad is pushed towards another. Or you can make a flex sensor based on a single line of conducting material that has its electrical resistance increased when it bends since the conductive carbon particles move away from each other.

While you'll only need a very minimal amount of software and hardware to start working with integrated sensors like these (a MakerBot Replicator 2x is a mere US$2,500), you must remember that you’re making prototypes, and not finished products. There are significant restrictions on the resolution of the sensors that this method is able to produce, and you’re probably not going to end up with a reliable standard for absolute measurements. But think of the things you print as iterative (and practically disposable), and this technique offers a lot of possibilities.

For technical details, like what kind of filament you need and what software all of this stuff runs on, the researchers have published a paper that was presented this week at the INTERACT 2015 conference in Bamberg, Germany.

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.