I’m not ashamed to admit it—my soldering skills stink. That puts a real crimp in my ability to prototype circuit ideas. Breadboards work, but by design, they significantly constrain how you can arrange components.

So I was excited when I spotted a preprint article on ArXiv.org describing a new liquid-metal ink. Conductive inks made from silver nanoparticles have been available for some time; recently, a group at Georgia Tech demonstrated a way to use them in inkjet printers to create custom circuits. But they are quite pricey, and I’m not keen on the idea of pumping metal through my printer. In contrast, this new ink can be used in an ordinary roller-ball pen to draw circuit traces, and the recipe for making the ink is amazingly straightforward: Mix 75.5 parts gallium with 24.5 parts indium in a beaker of deionized water, heat to 50 °C, stir, and voilá: an alloy that’s liquid at room temperature, costs about US $1 per milliliter, and is two orders of magnitude more conductive than the nanoparticle inks; its resistivity is just 17 times that of copper. This I had to try.

I phoned the senior author on the paper, professor Jing Liu of the Technical Institute of Physics and Chemistry at the Chinese Academy of Science, in Beijing, to check that this was really something I could do at home. Use 99.9 percent pure gallium and indium, he advised; I bought the metals from GalliumSource.com for about $130. The pen cartridge needs to be completely clean before filling, and the liquid alloy must be free of any solid bits that might clog the tip. Most important, write on plastic transparencies. The surface tension of the ink is so high that it beads up on paper.

loyaltyshopping_cartlocal_librarydelete

My son’s 11th birthday was coming up, so I decided I would try to make a fun gadget—a four-key organ with light-sensitive vibrato—that could go into a birthday card, with the transparency stuck facedown in the card to protect the ink. I settled on a design that uses two 3-volt button-cell batteries, four push-button switches, a photoresistor, a 555 timer integrated circuit, and assorted capacitors and resistors, all linked by hand-drawn traces. But first I’d need to make the ink and fill a pen.

Making the ink was easy. The metals blended readily, and I sucked the conductive ink into a syringe. I bought a high-quality roller-ball pen and some “bold-tip” (0.8 millimeter) cartridges, which I thought would be ideal for dispensing the alloy. Bearing Liu’s warning in mind, I realized the tricky part would be getting the regular ink sitting in the cartridges out.

My first thought was to bleed the pen dry. I placed the pen onto a folded paper towel, tip down, and let it sit overnight. Sure enough, the ink wicked away into the towel. I drilled a hole through the metal base of the cartridge, confirmed that it was empty, and squirted in the alloy.

Liquid metal immediately started emerging from the business end of the pen—but not from the roller ball. It was weeping silvery teardrops from air holes a few millimeters up the cartridge and making a terrific mess. (I was glad I was wearing gloves; gallium and indium are not good for your skin.) I plugged the holes with wax—and the pen refused to write. I shook it hard, tried again and—yes! No. It was normal ink that came out, not metal.

I sliced the cartridge open to see what had gone wrong. Inside I found a firmly attached plastic, bottlebrush-shaped wick that was lousy with the original ink. I would need a simpler kind of cartridge.

After two more failed attempts with different cartridges, I finally found an approach that worked. I syringed the ink from the open end of a Uni-Ball Jetstream bold-point pen cartridge and then flushed it repeatedly with denatured alcohol until every drop of the original ink was gone. I dried it under a bright lamp for several hours before squirting in the liquid metal.

“This had better work,” I said between clenched teeth as I put pen to transparency. I let out a whoop as the letters I-E-E-E appeared as if in quicksilver. A check with the multimeter confirmed it: virtually no resistance.

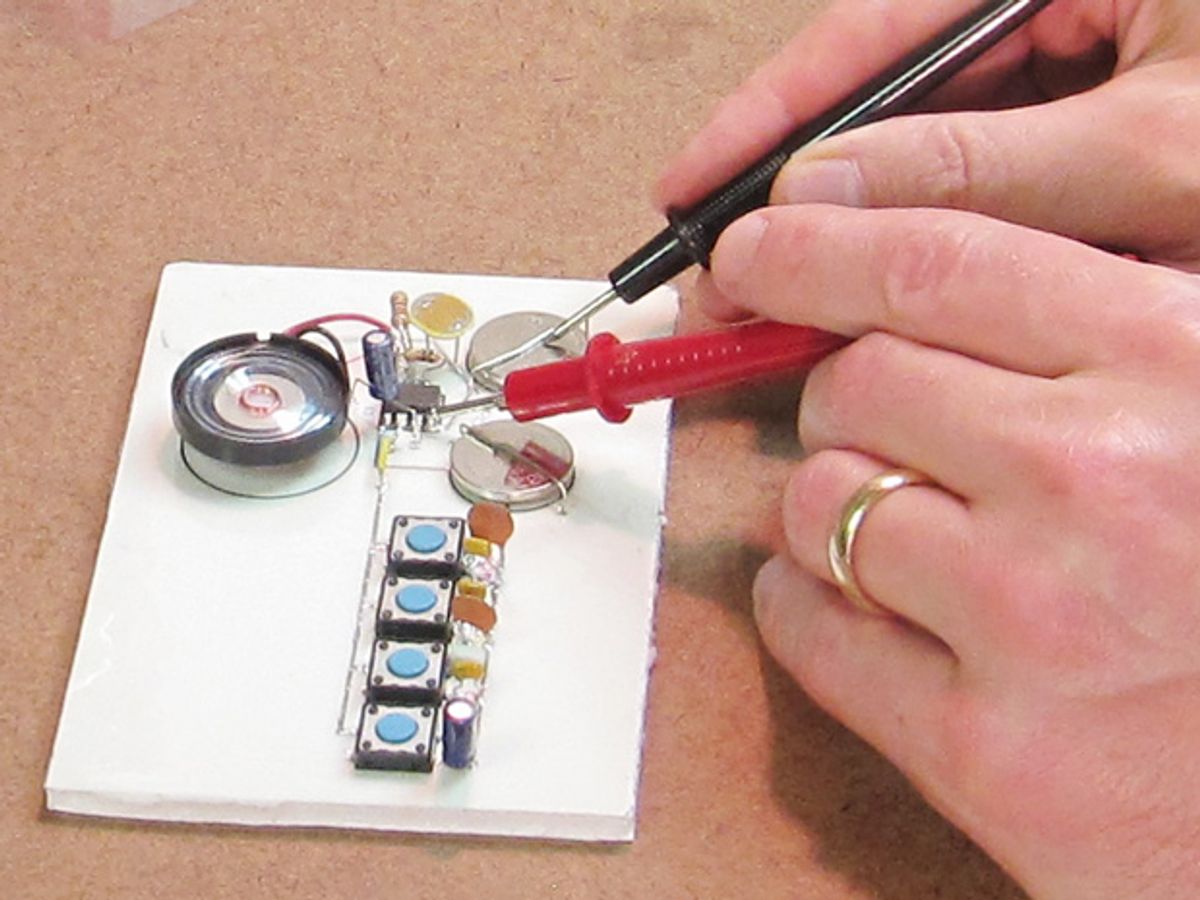

I inkjet-printed my circuit pattern, inverted, onto the rough side of a plastic transparency of the sort once commonly used with overhead projectors, and then I drew the traces on the smooth side. Because the ink does not dry, it is easily smeared, but my initial idea of protecting the circuit by sticking it face down was a nonstarter. On contact with a piece of foam board I was using as a backing, the traces spread out and collided, creating short circuits. But I was happy to find that the liquid metal adheres well enough to the plastic that it doesn’t run or drip when you upend the sheet. So I stuck the plastic to the board smooth side out, punched holes in the sheet with an awl to accommodate the leads of the components, drew the traces, and then mounted the components.

With great optimism, I pressed one of the buttons, then the others. No sound.

The problem evaded me for hours, until I eventually removed the batteries and saw what was going on. I had forgotten that with button cells, the positive electrode wraps around the rim of the battery: Invisible to me, one such electrode was contacting the inked-in ground lead. A few quick wipes with a cotton swab and the speaker crackled to life.

Expanded Version: Brew Your Own Conductive Inkyoutu.be

I tapped out the Mighty Mouse theme: “Here I come to save the day!” Though his birthday had by then passed, my young son got a big kick out of the project, and it provided lots of teachable moments about electronics. And not just for him.

About the Author

W. Wayt Gibbs is a freelance science writer in Seattle and a former editor at Scientific American. He has worked with Nathan Myhrvold at Intellectual Ventures on a variety of projects and was editor in chief of Modernist Cuisine: The Art and Science of Cooking.