Extreme ultraviolet lithography, the key process in making the finely featured chips of the coming decade, has had a long list of detractors, but its time seems to be at hand. The proof? ASML Holding, the Dutch company that makes most of the world's chip lithography tools, has sold six of its monstrous EUVL machines to six separate customers, including foundry behemoth Taiwan Semiconductor Manufacturing Co. These chipmakers will use ASML's NXE3100 to print the tiniest features of the most critical layers on their future chips.

The biggest roadblock for EUV over the past 10 years has been the light source, which has been nearly impossible to make sufficiently intense. Two competing technologies have faced off for years to be the preferred option for EUV customers. One will be in the first machines and is the current favorite for commercialization. But if some experts are correct, the other technology could win in the long run.

The two candidates—laser-produced plasma (LPP) and discharge-produced plasma (DPP)—each emit the needed light at a wavelength of 13.5 nanometers. LPP sources, the leading technology at this point, are being developed by San Diego–based Cymer and Japan-based Gigaphoton. DPP is being advanced by Xtreme Technologies, based in Aachen, Germany, a former subsidiary of Philips that is now owned by Tokyo-based lighting giant Ushio. ASML says that most of the NXE3100 units will contain Cymer's source.

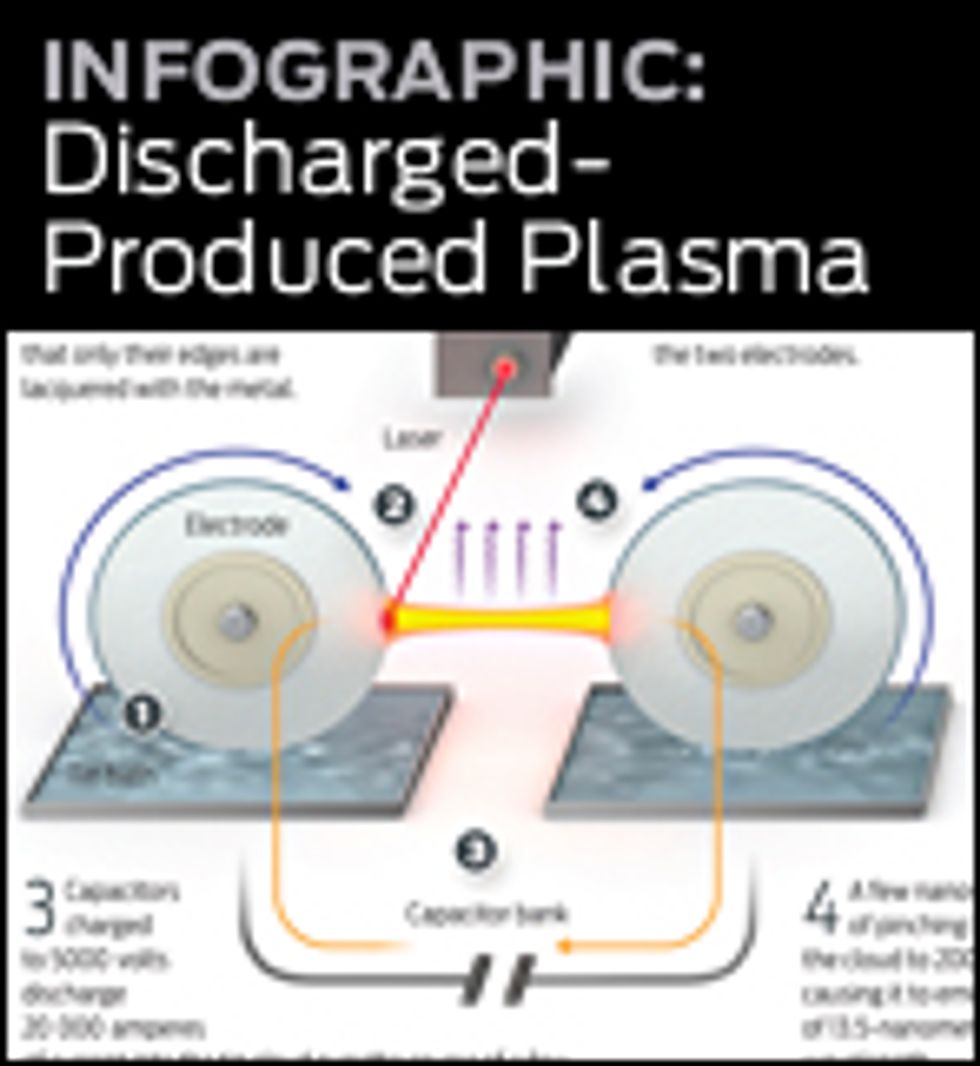

LPP sources blast falling tin drops with a high-power laser. When the laser-excited tin electrons return to their normal orbit, they emit EUV photons, which are harvested and funneled into a stream that eventually ends up casting the chip pattern onto a wafer. Xtreme's DPP light source is different. Instead of falling tin droplets, it blasts a lightning bolt's worth of current through a tin vapor to form the 13.5-nm photons.

By numbers alone, LPP appears to vastly outperform DPP. The eventual power goal for EUV volume production is 250 watts. (The brighter the light, the less time the wafer needs to be exposed to it.) In April, Gigaphoton reported that its LPP prototype met a major benchmark, producing 104 W. Contrast that with Xtreme's DPP technology, which produces only 34 W.

So it's a bit surprising that ASML has also expressed faith in that seemingly inferior technology. "There is a chance that one of the 3100s will be fitted with a DPP source," an ASML spokesperson toldIEEE Spectrum. And ASML's Noreen Harned says future EUV machines will be "source agnostic." These NXE3300 machines, due to ship in 2012, will allow customers to plug in either LPP or DPP.

The two LPP firms and Xtreme "all have credible plans," says Harned, who is ASML's vice president of technology marketing. Though she acknowledges that Xtreme's source is not yet ready for ASML's scanner, she still insists that her company expects that it will be. ASML knows what Xtreme is doing to boost its machine's output, Harned says. "We think it's going to catch up."

Chaohai Zhang, a professor of electrical engineering at Harbin Institute of Technology, in China, who studies DPP sources, thinks it will more than catch up. He says DPP may surpass LPP in the long run for four reasons: It uses power more efficiently, is smaller, keeps the lithography optics cleaner, and should last longer. LPP requires wall-plug power an order of magnitude higher than DPP to produce the same number of photons, says Marc Corthout, president of Xtreme. The DPP architecture also takes up less space, which is at a premium inside the EUV tool. Finally, Xtreme mitigates EUV's well-known contamination problems with a trap that prevents tin droplets from spattering the collector mirror and thereby dimming the EUV light. Corthout says less contamination contributes to DPP's greater longevity.

And there's one more thing, according to Corthout: The reported source power numbers that make DPP look so unappealing may be misleading. Industry insiders acknowledge that there is no standard for reporting the power of these systems. Gigaphoton's 104 W, for example, was delivered in very short blasts. While Xtreme's DPP power may appear low, it is continuous.

Corthout maintains that a lithography tool will be more effective with a continuous beam of light. Cymer disputes that claim, but there are no concrete data yet to prove it either way.

Before the end of 2010, one of ASML's six customers will have created wafers with the NXE3100, Harned says. Xtreme won't be the one providing the light source, but if Corthout and Zhang are right, eventually DPP will prevail.