Researchers have "unzipped" carbon nanotubes into graphene nanoribbons using a variety of methods since the feat was demonstrated over five years ago.

But there has always been one unifying characteristic about those methods: they involved a chemical solution to get the tubes to transform into sheets. Now researchers at Rice University have discovered that if carbon nanotubes are shot at a target and hit it broadside, they unzip into the graphene nanoribbons.

In research published in the journal Nano Letters, the Rice team fired pellets of randomly oriented, multi-walled carbon nanotubes from a light gas gun. The pellets impacted an aluminum target in a vacuum chamber at about 15,000 miles per hour. While the nanotubes that impacted the target end first would just get smashed, the ones that hit the target broadside would mechanically unzip.

“Until now, we knew we could use mechanical forces to shorten and cut carbon nanotubes,” said graduate student Sehmus Ozden in a press release. “This is the first time we have showed carbon nanotubes can be unzipped using mechanical forces.”

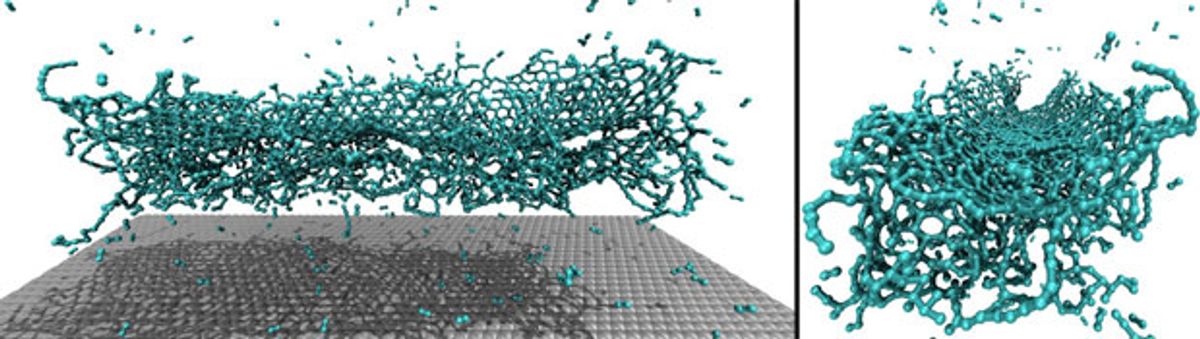

Computer simulations of what was occurring revealed that when the multi-walled carbon nanotubes struck the target, the outer tubes would flatten and hit the inside tubes, which led them to unzipping. In the case of single-walled nanotubes, the bottom wall hits the inside of the top wall, which leads to the tube unzipping from the middle out the edges.

It would appear that this mechanical approach would eliminate the chemical residues that can contaminate the resulting graphene produced from the chemical-based unzipping of carbon nanotubes.

Graphene is a desired material because its remarkable electrical properties could lead to next-generation electronic devices.

“One-step, chemical-free, clean and high-quality graphene nanoribbons can be produced using our method," said Ozden.

It's a promising process but it only results in 70 to 80 percent of the nanotubes in a pellet to unzip, and of that amount not all unzip to the same degree. As a result it is hard to picture how this mechanical process can match the chemical methods in terms of scale up. The previous chemical approaches were simply bulk chemistry, even if it did require another process to remove residues.

The competing methods for producing graphene nanoribbons have been well catalogued, and for the last few years it would seem that other graphene production methods have gained the most interest, most notably chemical vapor deposition. Whether this mechanical approach can bring unzipping back into the running as a preferred option for producing graphene remains to be seen.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.