For all the talk and research that has gone into exploiting graphene’s pliant properties for use in wearable and flexible electronics, most of the polymer composites it has been mixed with to date have been on the hard and inflexible side.

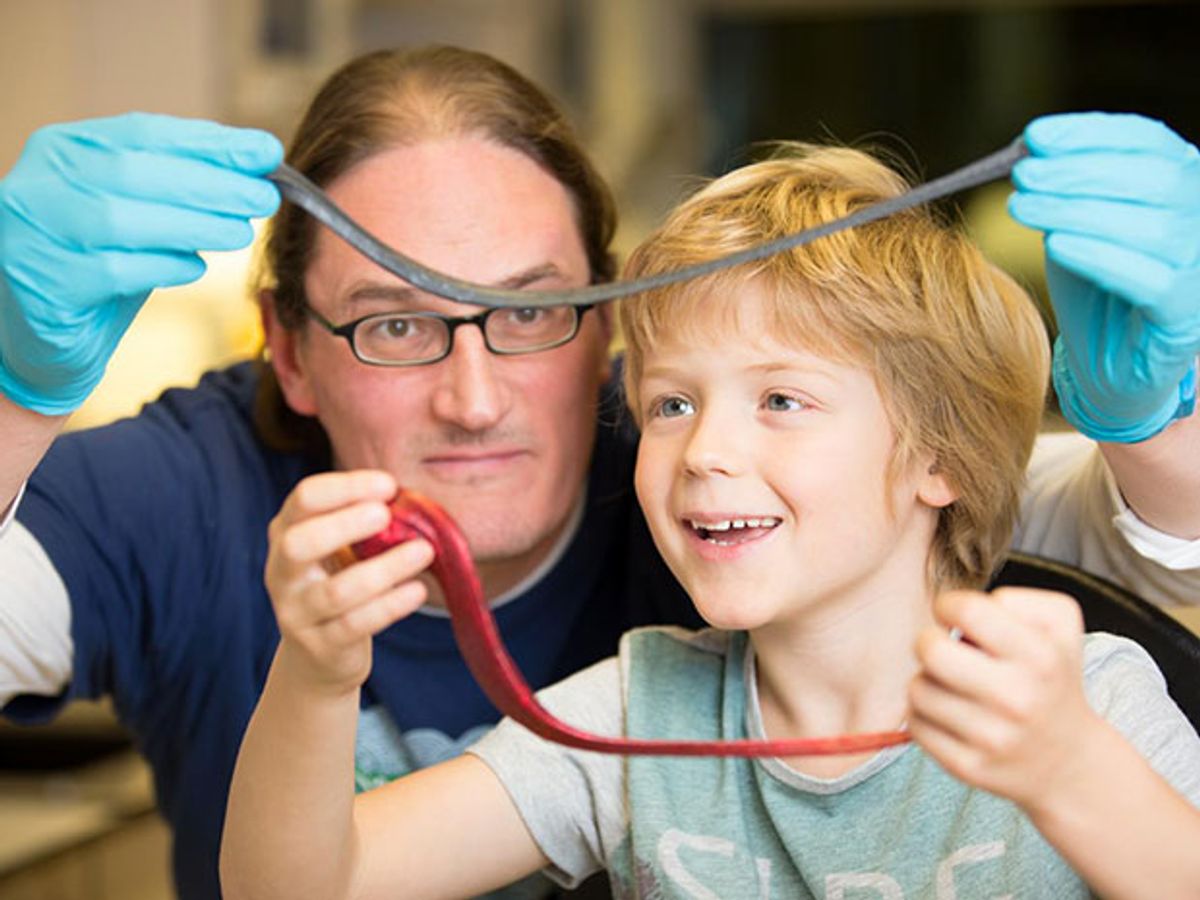

It took a team of researchers in Ireland to combine graphene with the children’s toy Silly Putty to set the nanomaterial community ablaze with excitement. The combination makes a new composite that promises to make a super-sensitive strain sensor with potential medical diagnostic applications.

In research described in the journal Science, scientists at AMBER, the Science Foundation Ireland-funded materials science research center based at Trinity College Dublin, discovered that if you added nanosheets into a low-viscosity material like silly putty, its electromechanical properties dramatically changed. You suddenly have an extremely sensitive strain sensor.

When you apply a voltage to the graphene-infused silly putty, the slightest touch results in a very large change in the current. Voila a strain sensor.

“If you take the silly putty and stretch it just by one percent, then the current would change by a factor of five: that’s a very small mechanical change with a very big electrical change,” says Jonathan Coleman, the professor at Trinity College Dublin, who led the research.

In tests with the graphene-enabled putty, the researchers placed the composite onto the people’s chests and necks to measure breathing, pulse, and blood pressure. The results demonstrated an unprecedented sensitivity for a strain and pressure sensor, hundreds of times more sensitive than other sensors.

“What we found is that when you put graphene in extremely soft polymers like this, they act as strain sensors that are light years ahead of anything that had been created before,” says Coleman. “And this is intimately linked with the fact that these polymers are so soft.”

What is surprising about this line of research is that there has been so few investigations previously looking at combining graphene with a low-viscosity polymer. Graphene has been put in many different polymers to make composites, but the vast majority of those polymers are at the harder end of the spectrum. This practice is typically driven by the aim of adding graphene to a strong, hard polymer to make it even stronger and harder.

While there has been some work in putting graphene into soft polymers, no one has put graphene into polymers anywhere near as soft as silly putty. The softest polymer that people had put graphene in previously would be something like rubber, according to Coleman.

Just as there has been a lot of work into adding graphene to polymers, the use of graphene to make a polymer a strain sensor has some history as well. But no one was quite expecting that these softer materials would enhance the effect so profoundly.

“We knew that there had been very little work done in this area,” said Coleman. “But I have to be completely honest, we didn’t know that the material would have the interesting properties that we saw in the end result.”

While Coleman believes that there is a wide range of medical sensing applications for the material, by far the most clear-cut and important example would be the continuous measurement of pulse and blood pressure.

“We can measure pulse in a relatively straightforward way,” he says. “There are a number of ways to do it. But we can measure blood pressure simply, cheaply and continuously.”

You can see a demonstration of this blood pressure monitoring in the video below:

Coleman is pretty confident that the path to commercialization for this technology is pretty clear with no major obstacles in sight.

“First of all you would have to have a commercial supply of the material; I don’t see that as challenging,” said Coleman. “There are many commercial suppliers of graphene that can produce graphene in large quantities. And, of course, silly putty is commercially available. The procedure of mixing the two components together is fairly straightforward and that could certainly be industrialized. So making the material is not a problem.”

Engineering the sensing device would be a bit more of a challenge. Coleman explains that you would have to make some kind of housing that could be worn on the wrist and would have the sensing material inside of it. Then you would need the electronics to generate the current and measure the changes in it. You would also need some kind of communication system that would send the signal to a mobile phone where you would need an app to collect and analyze the data.

“To be completely honest, all of that stuff is not that far from being off-the-shelf,” he says. “I don’t think there is a great engineering challenge in this work. So really we are actually quite close to the ability to commercialize this material.”

While the strain sensor that Coleman and his colleagues have developed is sensitive, he believes that this research opens up an entirely new way of making composites that will lead to far more sensitive sensing technologies in the future.

“What we really want to do is to go on to the next generation of sensing,” he says. “We have extremely sensitive materials here, but we see an opportunity to make composites in a different way using different polymers that are up to a factor of ten more sensitive than the ones we have created here.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.