“Everything is a mess,” Rodney Brooks says, as we make our way through a brick-walled room filled with robots in various states of assembly here at Rethink Robotics’ headquarters in Boston, Mass. The mess, we should point out, makes Brooks, the company’s founder and CTO, very happy. It means things are busy. The past few weeks, he says, have been particularly hectic. That’s because today Rethink is making its collaborative factory robot Sawyer available for purchase.

As robots whir around us, Brooks waves toward a cluster of empty (and messy) cubicles that one team of engineers normally occupies. “Last week, there was so much activity,” he says, “now they are all gone.” Some headed out for Silicon Valley and Las Vegas to demonstrate Sawyer at trade shows, while others are deploying robots at customer sites around the world, Brooks [pictured below with a Sawyer] tells me.

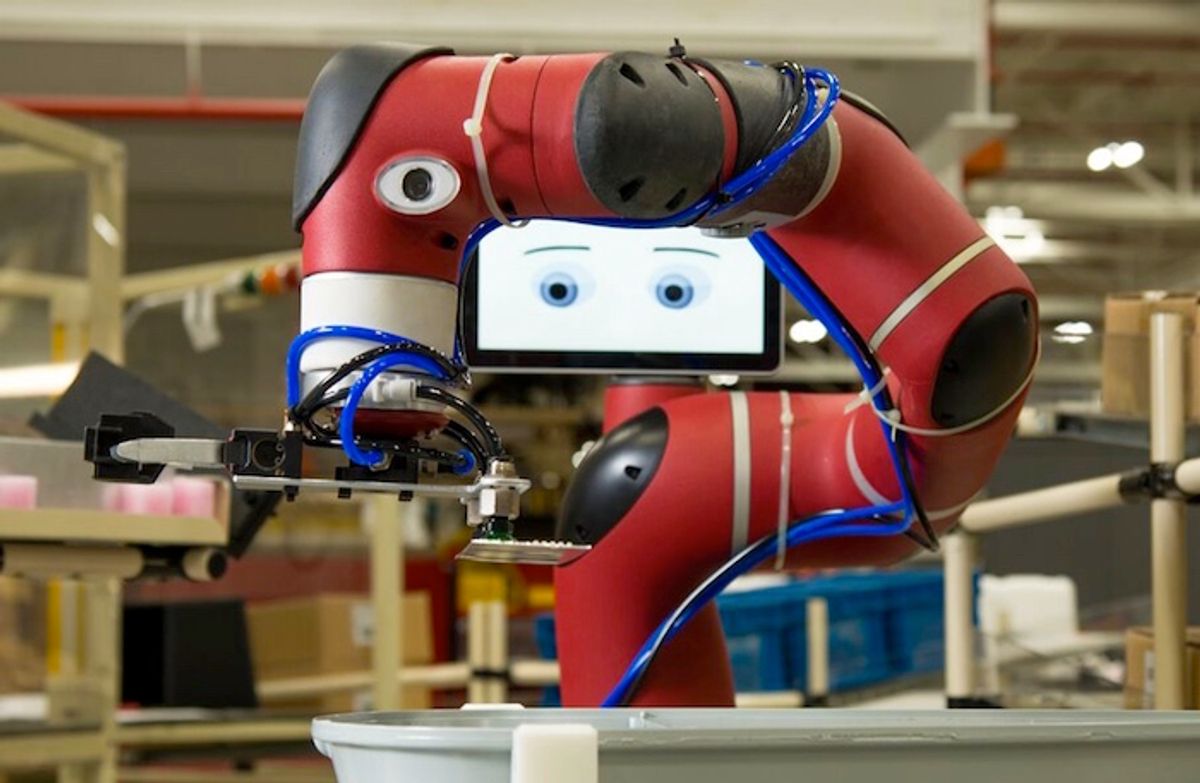

Rethink introduced Sawyer, the company’s second robot, earlier this year. Like Baxter, its predecessor, Sawyer can safely operate alongside human workers, who can teach the robot to perform tasks simply by moving its arm though a series of motions. But whereas Baxter has two arms and can help with packaging and material handling tasks, the single-arm Sawyer is designed for tasks that require more precision, including machine tending and circuit board testing.

To achieve that, Rethink redesigned its series elastic actuators, adding a new titanium spring as well as Harmonic Drive servos. This means Sawyer can measure forces on its joints with greater precision, allowing it to perform tasks like placing a part into a machine by “feeling” when the part is on the right spot. It also means Sawyer is more expensive, at US $29,000 (Baxter is $25,000).

One spec, not announced until today, is the robot’s repeatability: Sawyer can perform tasks that require 0.1 millimeters of tolerance, much better than what Baxter can do. Both robots have 7 degrees of freedom, but Sawyer’s arm has a greater reach (1260 millimeters) and payload capacity (4 kilograms). It also has a Cognex camera on the wrist, making recognition and inspection of parts easier.

Rethink hopes that these features will help Sawyer stand out from the competition—most notably the UR3, UR5, and UR10 robotic arms from Danish firm Universal Robots, which has sold about 4000 robots all over the world (and was acquired by automatic test equipment company Teradyne for $350 million in May).

Rethink doesn’t say how many robots it has shipped, and it’s unclear whether Baxter is selling “like hotcakes,” as Brooks had hoped. With the development of a second robot, the stakes are higher for the seven-year-old company, which has raised $113.5 million from investors that include Bezos Expeditions, Charles River Ventures, Draper Fisher Jurvetson, and Goldman Sachs.

Perhaps that’s one reason why Rethink wants to offer Sawyer to customers worldwide. With Baxter, the company put a lot of emphasis on the North American market. For Sawyer, Rod Brooks says that, in addition to North America, “our big targets to start with are China, Japan, Western Europe, and Mexico.”

I asked Brooks why Rethink didn’t build Sawyer first, instead of Baxter, if that’s what more customers seem to want. He explains that there are customers for both robots. Baxter can use its two arms to grab and move things over bigger work areas than Sawyer. But thanks to its precision and force sensitivity, Sawyer can, for instance, place a part inside a CNC machine, close its doors, and press the start button, tasks that are difficult for Baxter. Sawyer can also do some more advanced tricks, such as using its Cognex camera to re-register its coordinate system in case the robot or things around it get moved.

Rethink says companies already using Sawyer include GE Lighting (GE Ventures is an investor in Rethink), where the robot works on a production line positioning parts into a light fixture, and office furniture maker Steelcase, which taught Sawyer how to place parts into a welding machine:

Like a parent who doesn’t want to pick a favorite child, Brooks says that both Baxter and Sawyer will coexist, and indeed, the software that powers the two robots is the same. “And in the future there may be more robots,” he says. But when asked what kind of robot could be next for the company, he declines to elaborate. “We’re not going to come up with a 50-kg payload robot, I’m pretty sure of that. But there will be different robots for different niches.”

Which means the mess at the Rethink office will keep growing, and that’s just how Brooks likes it. “It’s an exciting time for us.”

[ Rethink Robotics ]

Erico Guizzo is the director of digital innovation at IEEE Spectrum, and cofounder of the IEEE Robots Guide, an award-winning interactive site about robotics. He oversees the operation, integration, and new feature development for all digital properties and platforms, including the Spectrum website, newsletters, CMS, editorial workflow systems, and analytics and AI tools. An IEEE Member, he is an electrical engineer by training and has a master’s degree in science writing from MIT.