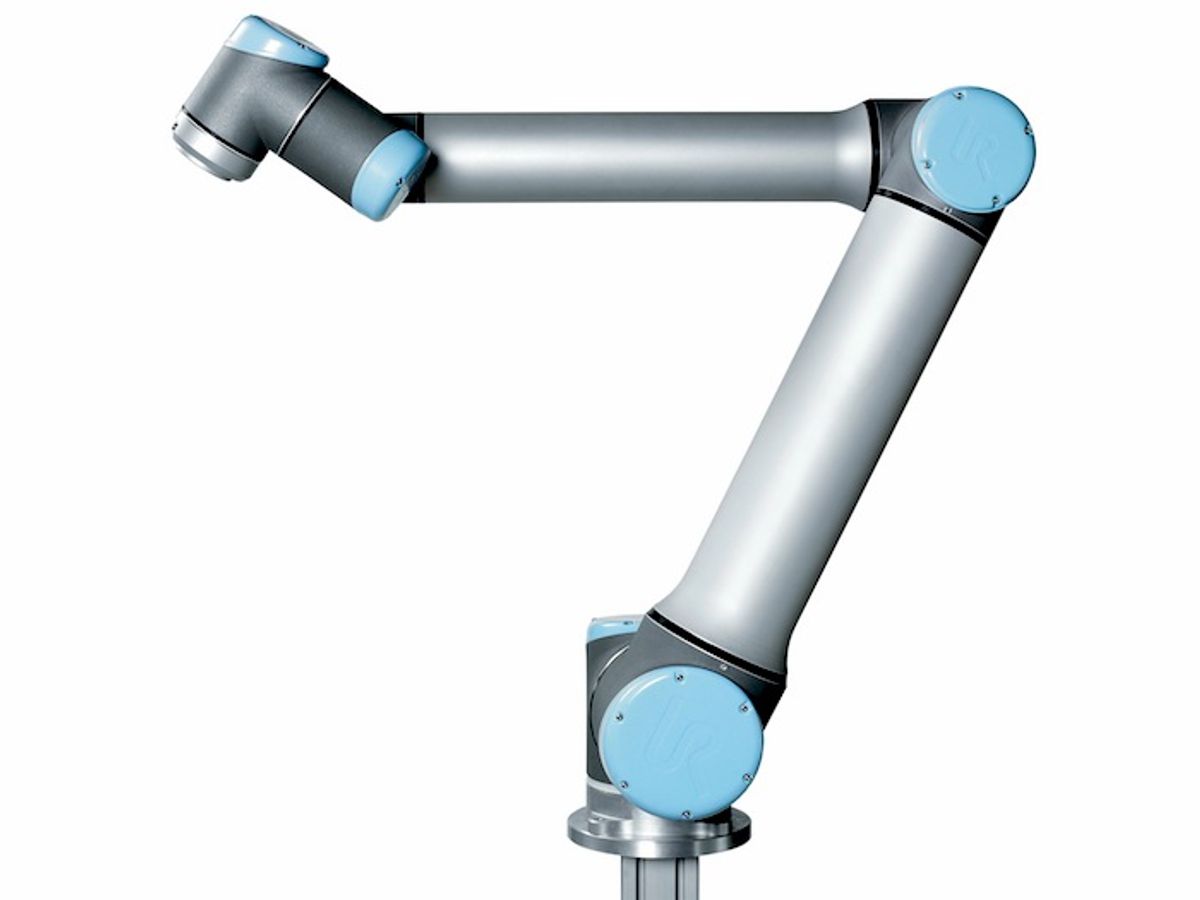

Last month, Enrico Krog Iversen, the CEO of Universal Robots, showed up at the IEEE Spectrum office in New York City with a large cardboard box. Inside was a shiny, sleek gray-and-blue robotic arm, and before I could hand him my business card, Iversen and one of his engineers had set up the robot on the conference room table.

We had bots in the office before, but this was the first time someone brought in an industrial robot. Iversen told me that the UR-5 is different from other factory robot arms because it’s compact and lightweight (they carried it on a hand truck all over Manhattan), easy to program, and affordable. It’s also safe for people nearby, even if it bumps on them, a feature that Iversen was willing to demonstrate using his own body.

He showed me how you can program the robot simply by grabbing it, moving it around, and tapping on a touchscreen. I found the tablet interface a bit user unfriendly (there are dozens of menus, buttons, tabs, and panes crammed on the screen), but with some guidance I was able to create my own “application,” making the arm push a plastic cup into a trash can:

Sure, it’s a silly “application.” But if a reporter can do that after 10 minutes with the robot, imagine what a factory worker or technician can do in a real manufacturing environment.

In fact, Universal Robots, based in Odense, Denmark, has sold about 4000 robots all over the world (the UR-5 sells for US $35,000, and a more powerful model, the UR-10, costs $45,000). The robots are used to automate tasks such as machine tending, packaging, gluing, painting, polishing, and assembling parts.

Before the demonstrations, I spoke with Iversen about the company’s technology, the competition, and its expansion plans. The following has been condensed and edited for clarity.

IEEE Spectrum: When the three founders [Esben Østergaard, Kasper Støy, and Kristian Kassow] decided to start Universal Robots, were they working on a technology they believed was unique?

Enrico Krog Iversen: One of the founders did a lot of research in modular robotics, and had previously built robots with multiple joints. It wasn’t exactly like the UR arms, but basically the idea was the same—robots that were safer, flexible, and much easier to configure, program, and use than traditional robots. So, yes, they believed they had something unique.

Spectrum: And what is the technology they created? What makes the UR robots different from other industrial robots?

Iversen: What makes the robots different is their design and flexibility. You have plus/minus 360-degree movement on all of the joints, which isn’t common in the industry. You have safety features that allow people to develop collaborative applications in which robots and humans share the same workspace—that’s a huge step forward. And then there’s the easy programming, where you learn how to program a robot in a couple of minutes rather than in a couple of months. I think that was sort of what opened up the possibility to start “robotizing” a lot of applications that you could not or would not automate with traditional robots.

Spectrum: But let’s go deeper. What is the technology? What’s inside the arm in terms of motors and gears and electronics?

Iversen: Inside each joint you have a motor that we have designed and developed together with the motor manufacturer. You have a gear that we have designed and modified together with Harmonic Drive. You have a bunch of electronics. You have our encoder system. You have all that in each joint, basically making each joint its own little servo unit. And then we have software that allows the joints to communicate. It’s a Linux-based system that we developed ourselves. And on top of that we have a Java-based user interface, which takes all of the complicated stuff that we’ve done in the robot and presents that in a very user friendly way.

Spectrum: I read that the arm has no force/torque sensors, and measures forces by monitoring the current on the motors. Is that how it works?

Iversen: [Laughs] That’s getting into our proprietary stuff, so I’m not going to talk in detail. Let’s just say that we have a technology that allows us to monitor forces and to use that information in our safety system and also as part of our programming interface—there’s a force control feature that we allow people to use when they are developing their applications.

Spectrum: So without sensors to detect forces directly, do you have to do a substantial amount of computations?

Iversen: The robot uses a standard industrial PC. We have it set up to do all the calculations: it’s constantly monitoring speed, momentum, force. It’s all calculated on each of the joints and also in the controller. And then every 8 milliseconds they also “align” their calculation, and if there’s no alignment, then the robot will go into a safety mode. The safety system is largely software based. Software is very important. Without the software we created, this robot wouldn’t be possible.

Spectrum: Why can’t the big guys like Kuka or ABB just go and buy some harmonic drives and build a robot like that?

Iversen: I think they have a different mindset and different focus. The market for collaborative robots is quite hot right now, so I believe we’ll see other people getting into this space. But we’re going to continue pushing our technology. Our R&D people will develop new features that can increase the value of our robots for our end customers. Because regardless of how “cool” the technology can be, customers are not buying technology; they are buying savings, they are buying decreased unit costs in their manufacturing. So we have to take an interesting technology and basically turn that into a machine that starts printing money for our customers.

Spectrum: Tell me a bit about the competitive landscape.

Iversen: The competitive landscape, there’s Baxter, and also Kuka with its lightweight arm also moving into this space. We have some other companies currently developing this type of robot like the Roberta [by Gomtec] in Germany. But all of them are focusing on the actual arm and basically asking their customers to go and get a third-party controller. So if you look at the market today, we’re the only ones that can supply a complete solution where you get both the safe arm and the easy programing in one package. The only parts we don’t supply are grippers, sensors, vision systems. All of that comes from our partners and integrators and they will build the complete solutions and deploy them at the end-users. And now we also have a kind of app store, where integrators and others developing applications using our robots can market and sell their solutions. Our platform is free, we don’t charge.

Spectrum: You’re nicer than Apple.

Iversen: Yes we are! [Long laugh]

Spectrum: Say I’m a plastics company and I want to buy a robot to do some manufacturing tasks: Why would I get a UR5 that has one arm and not a Baxter that has two arms and a bunch of cameras?

Iversen: I can tell you what you get with a UR robot and you can make the comparison yourself. With Universal Robots you get a repeatability of a few hundredths of a millimeter. You get a speed of up to 8 feet per second. You get an ability to move completely free, with 6 degrees of freedom in all directions. You get a user interface that allows you to setup material handling programming in a couple of minutes and allows you to integrate any kind of gripper—vacuum grippers, small griper, large grippers. And you get the possibility to hang the robot on the wall or from the ceiling or mounted on a machine—whatever it takes the least possible space and where it’s just easier, so it’s just folded away when you don’t need it. So I think you get a lot of advantages.

Spectrum: Tell me about the company’s latest results—how many robots did you sell in 2014, and what are your plans to grow?

Iversen: We’ve been basically doubling every year, and this year we’re expecting to grow 137 percent. Just to put things into perspective: in two or three days this year we’ll sell as many robots as we did in all of 2009. That’s how much we’ve been growing. We did a little less than 2000 robots last year. We’ll do around 4000 this year, with revenue close to $100 million. Then next year and the year after, later in 2017, we should hit $200 million. That will be about 9,000 to 10,000 robots.

Spectrum: And in what parts of the world are you seeing the biggest growth?

Iversen: Basically our sales are about half in Europe, a quarter in the Americas, and a quarter in Asia. That will probably change. I think we’ll see a development where Asia and North America will probably be equal to Europe as we look at future sales. Asia is starting to move, and China is very hot right now for robots. But at the same time, we’re doubling our sales in North America every year, and we’re starting to see some developments in parts of Latin America. For the United States, in particular, we’re setting up offices in the Midwest and also on the West Coast to make sure we have sales people and technical support close to our customers and potential customers. We have four people in North America and we’ll have 12 by the end of the year. For the whole company we’re 150 employees now and we’ll be 190 by the end of the year. When I joined the company, there were only the founders, and I was employee No. 4.

Spectrum: Are you going to continue with UR-5 and UR-10 for a while, or are you planning to develop a new robot?

Iversen: I don’t have anything to tell you today, but we’ll be at the Automate show in Chicago and might have some news there, so stay tuned.

Erico Guizzo is the Director of Digital Innovation at IEEE Spectrum, and cofounder of the IEEE Robots Guide, an award-winning interactive site about robotics. He oversees the operation, integration, and new feature development for all digital properties and platforms, including the Spectrum website, newsletters, CMS, editorial workflow systems, and analytics and AI tools. An IEEE Member, he is an electrical engineer by training and has a master’s degree in science writing from MIT.