Your Guide to Television’s Quantum-Dot Future

Move over, OLEDs. Quantum dots will be the next darling of display manufacturers

The future of the television set was supposed to be simple. At some point in the near future, LCDs were supposed to become obsolete and give way to bright, sharp, and incredibly thin OLED displays. It turns out that the near future of TVs isn't going to be so simple—but it sure is going to be bright.

The reason? Quantum dots. If you've shopped for a TV lately, you've probably been dazzled, or more likely perplexed, by the array of new acronyms being splashed around by the best-known TV makers. Perhaps you've wondered what they mean by QD, QUHD, SUHD, and ULED. We're here to help. Each of these trade names refers to a quantum-dot technology available today. We'll explain the different approaches as well as other ways quantum dots will be used in future television displays. Even if you've had your heart set on an OLED TV, we think you'll find the coming world of very-high-performance quantum-dot displays appealing. For one thing, this emerging technology is going to finally make possible the printable, rollable, and wallpaper-ready televisions that we've all been promised for the past 20 years.

But to understand how televisions are going to make this, er, quantum leap, first consider why people are using quantum dots for TVs in the first place.

At just a few nanometers in diameter, a quantum dot is a tiny semiconductor, typically zinc selenide, cadmium selenide, or indium phosphide. It can do lots of useful things, but here we're mainly interested in its ability to convert short-wavelength light—typically blue (450 to 495 nanometers)—to nearly any color in the visible spectrum.

When a quantum dot absorbs a photon, it generates an electron-hole pair that recombines to emit a new photon. Crucially, the color of this emitted photon depends on the size of the quantum dot: Bigger dots emit longer wavelengths, close to red (620 to 750 nm); smaller dots emit shorter wavelengths, closer to the violet end (380 to 450 nm) of the spectrum. Such “tunability" is unique to quantum dots. In other light-emitting materials, the wavelength of the emitted photon is a fixed property of the material and not affected by its dimensions. To create a quantum dot with a specific size, which determines the wavelength, manufacturers adjust the temperatures and the timing of the chemical reactions used in their production.

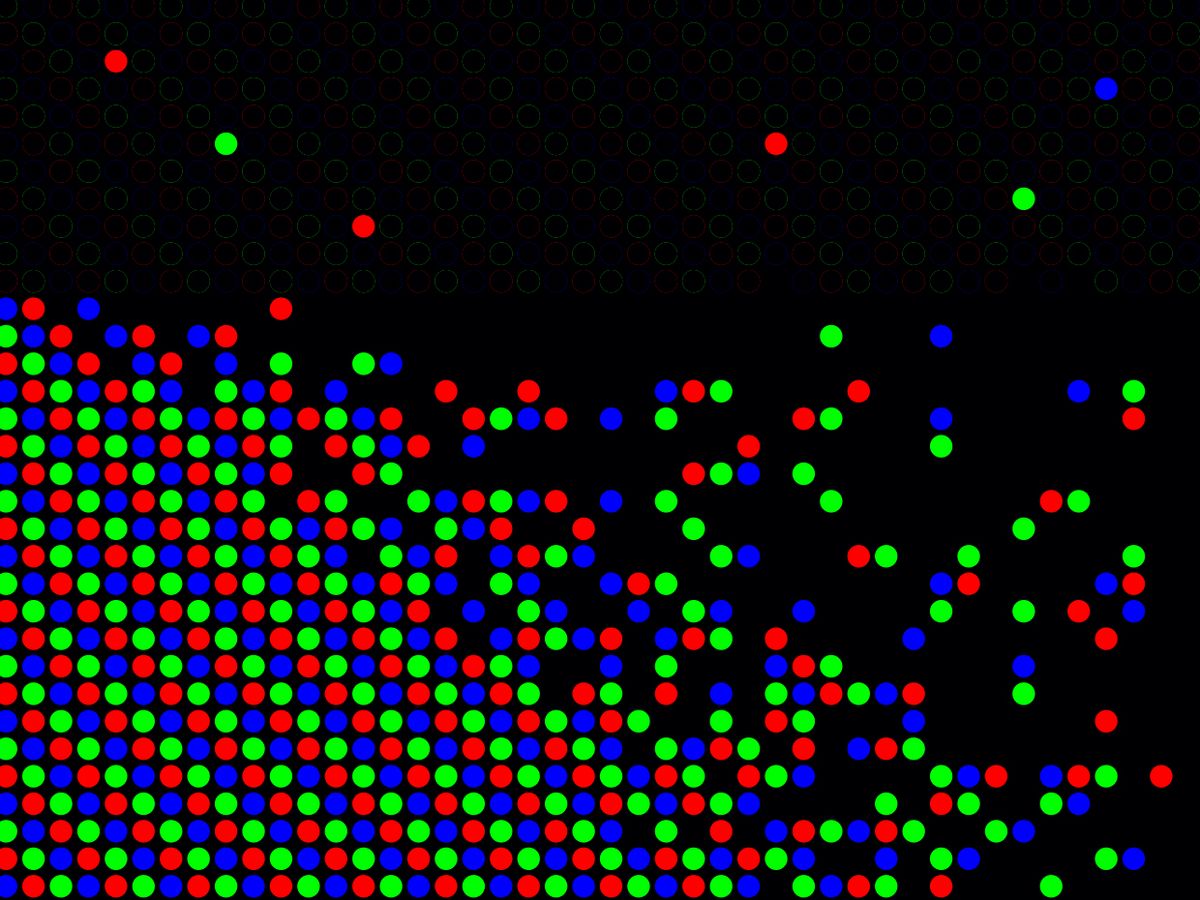

That's how the dots work. Now what does this have to do with the image on your TV screen? Every pixel you see on the screen emits red, green, or blue light, or some combination of all three, for a total of more than a billion unique shades. How accurately these shades match the colors recorded by the cameras on the street or in the studio depends on how exactly a TV reproduces the specified wavelengths—that is, how narrow the spectrum is for each color.

The Structure of a TV Display

Many of today's televisions use quantum dots to improve colors produced by liquid crystal displays (LCDs), backlit by light-emitting diodes (LEDs). Meanwhile, researchers are developing ways to use these dots to create even better quality television images. TVs made with organic LEDs, a competing technology long thought to be the next revolution in television, remain expensive.

-

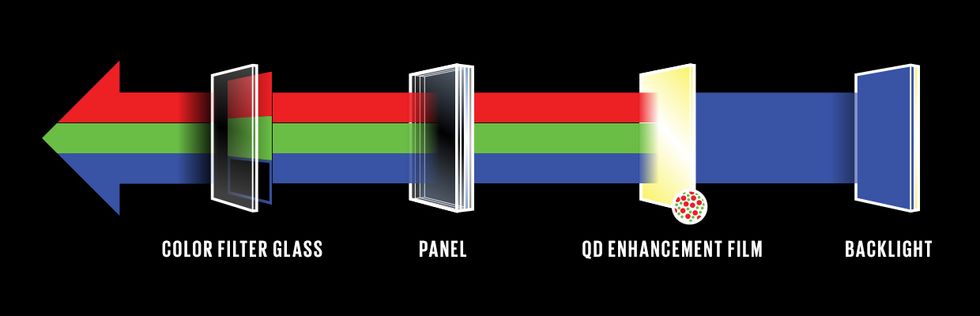

Photo-Enhanced Quantum-Dot TV

In this variation of LCD technology, quantum dots inserted between an LED array and color filters purify the television's backlight to improve color reproduction. Advantages: Deep color at high peak luminance • Low cost • No burn-in • Manufactured using existing LCD infrastructure • Available nowAll illustrations: James Provost

-

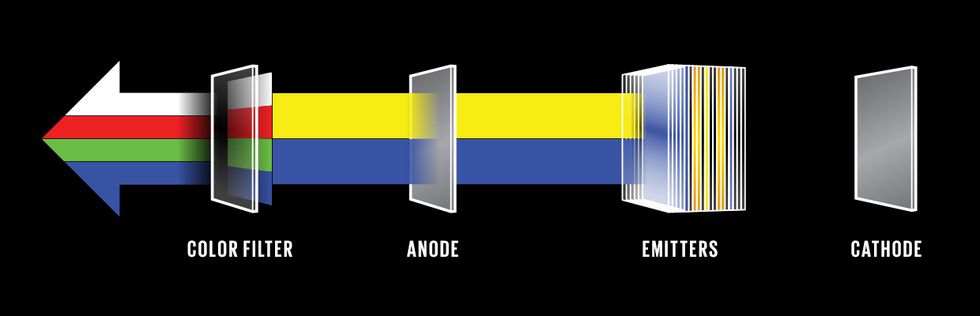

OLED TV

This ultrathin display technology doesn't involve quantum dots and was long thought to represent the future of television. Advantages: Deep black levels • Excellent viewing angle • Fast refresh • Can potentially be manufactured on flexible substrates • Available now

-

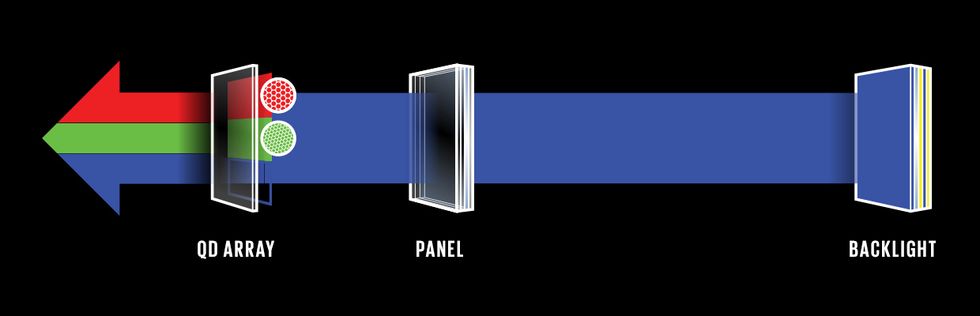

Photo-Emissive QD TV

The quantum dots replace the filters and become the red and green subpixels themselves; the blue backlight excites the dots and creates the blue subpixels. Advantages: Wide viewing angle • Potential threefold jump in efficiency and brightness over LCDs • Manufacturers can use existing LCD infrastructure

-

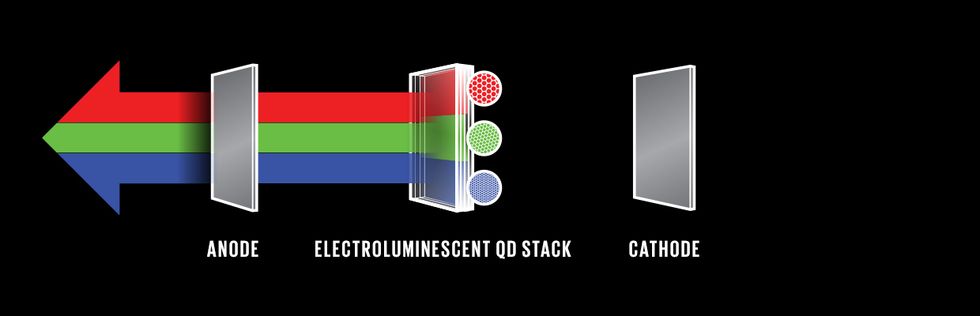

Electro-Emissive QD TV

These quantum dots emit light themselves when an electric current is applied, so no backlight is involved. Advantages: Perfect viewing angle • Perfect black levels • Potential low-cost manufacturing • Fast refresh rate • Flexible substrates • No filters needed • Long lifetimes

-

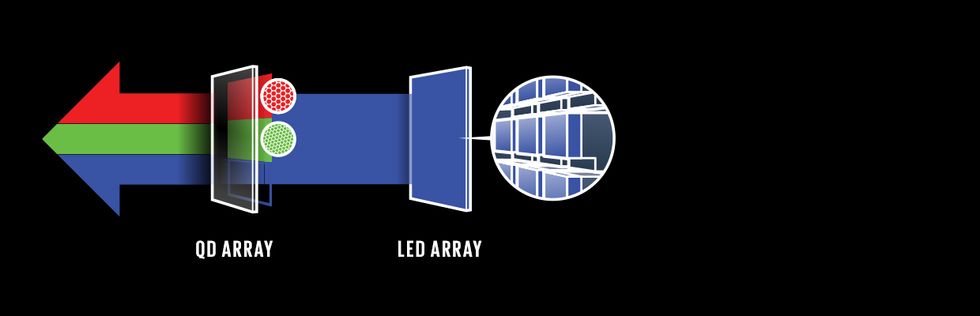

Micro-LED TV With QDs

This variation of micro-LED technology involves an array of microscopic monochrome LEDs, with quantum dots providing color conversion for the red and green subpixels. Advantages: Perfect viewing angle • No filters needed • Perfect blacks • Brightest technology • Fast refresh rate • Flexible substrates possible

Today's LCD televisions, the type you probably have in your home, produce colors using a light source—the backlight—that appears bluish white. Nowadays, that backlight is usually based on an array of white-light LEDs. (Older LCD models used fluorescent lamps rather than LEDs.) At each pixel, there are red, green, and blue subpixels. Each of these is just a tiny patch with a colored filter and a liquid crystal shutter that controls how much light streams through that filter. By varying the relative proportions of the light emitted by each of the subpixels, the pixel can create most of the colors that are reflected by the natural world. And the key point here is this: The purer the light at each subpixel, the narrower the spectrum and the more precisely colors can be mixed at that pixel.

LCD television manufacturers have two ways of making sure the spectrum of light coming from each subpixel is narrow. One method uses, at each subpixel, very strict filters, which allow only a narrow spectrum through in each of the primary colors of red, green, and blue. The alternative is to tinker with your backlight. Recall that white light can simply be a mix of red, green, and blue light. So another option for enhancing image quality is to create a backlight whose white light is a combination of these three colors, each of which has a spectral distribution with a sharp and narrow peak.

The best option by far is the latter. Narrowing the filter dims the image, never a good thing for television displays. So display engineers have focused on improving the backlight.

That backlight in a budget TV today works in much the same way as the white-light LED bulbs that are increasingly ubiquitous in our homes. These white LEDs efficiently produce enough of the visible spectrum to let us readily perceive it as white.

In a typical white LED backlight, a gallium nitride LED generates blue light. That light then excites an yttrium aluminum garnet phosphor, which generates yellow light. The yellow and blue together create a light that appears white but is rich in yellow and blue wavelengths and weak in green and red.

When the LCD subpixels on top of the backlight filter this light into red, green, and blue components, there is simply not enough energy at the required wavelengths of red and green to produce a bright image using just that light. The filters compensate for this lack of energy by letting through broader ranges of colors. So the green subpixel contains a mix of blue green through yellow green, while the red includes orange all the way through infrared. With such imperfect colors, it is impossible for the subpixels to mix light from those three primary components into the precise colors we see when we look around us at the world as lit by the sun.

That's where quantum dots come in. Inserting quantum dots between the LEDs and the filters can improve the picture by maximizing the amount of light coming through at precise red, green, and blue wavelengths, and by minimizing the energy used to produce light between those wavelengths [see diagram, "Photo-Enhanced Quantum-Dot TV," in "The Structure of a TV Display"]. A typical approach involves using an LED that emits blue light at 450 nm, paired with quantum dots coated onto a film that slides into the back of the display panel. The dots on that film are a mix of two versions: 1.5- to 2.5-nm-diameter dots emitting 527-nm green light, and 3.0- to 5.0-nm dots emitting 638-nm red light.

So in this setup, instead of using the blue LED to excite a phosphor that produces yellow light, the manufacturers use it to excite red and green quantum dots with sharp, narrow spectra, and also to directly produce the necessary blue light. This scheme more precisely matches the specifications for television color reproduction than the blue-yellow approach, and as a bonus, less light is lost when it passes through red and green filters.

This approach creates a “photo-enhanced" quantum-dot display. It gives quantum dots a supporting role in the TV display world—but it's only an interim step. The problem is that, even with the help of quantum-dot films, LCD TV displays still have some inherent flaws:

- Their viewing angle can be narrow. Newer liquid crystal technologies exist that overcome much of this problem, but they are expensive.

- They waste energy. At each subpixel, an LCD TV has to block about two-thirds of the light generated to separate red from blue and blue from green.

- They struggle with showing deep, dark, true blacks in low-light viewing environments. Because the liquid crystals aren't perfect light blockers, a small quantity of white light leaks through to the viewer. This can make black images appear closer to a dark gray (technically speaking, these images have “limited dynamic range").

- They have relatively slow switching speeds. These speeds stem from the very nature of liquid crystals. These crystals are actually twisted by an electric field, which polarizes the light coming through them. The polarization is used to block light or let it through at each subpixel. But this twisting takes time, and the lag can cause trouble for fast-motion content like sports, action movies, or gaming. The upshot is that LCDs can support a refresh rate of about 240 hertz, at best. Some state-of-the-art TV systems are already experimenting with such high refresh rates, though the traditional TV refresh rate is 60 Hz.

- They are not foldable or rollable, at least with available technology. That limits the form factor of today's displays.

These limitations have led many observers to conclude that LCDs will be replaced in the foreseeable future by an emissive display technology, namely organic LEDs (OLEDs). An emissive technology is one in which the subpixels themselves emit red, green, and blue light, rather than creating it with colored filters in front of a white backlight. Emissive technologies have natural advantages, like deep black levels, wide viewing angles, and, with some types of emissive technologies, faster switching times. The picture quality can be quite spectacular, but OLEDs have some lingering challenges, mainly in cost, power consumption, and longevity.

OLED technology involves inserting a thin film of an organic substance between two conductors; applying a current causes the film to emit light [see “OLED TV"]. Various small gadgets and smartphones by Samsung, Google, and now Apple use a kind of emissive display called RGB (red, green, blue) OLED. Unfortunately, it turns out that RGB OLEDs cannot be reliably manufactured in the large sizes needed for TVs. So TV manufacturers switched to a variant—white OLED, or WOLED. Today, LG Display is producing WOLED displays in TV screen sizes for its own use and for use by other TV vendors; Sony, Panasonic, and Samsung have gotten out of the business of manufacturing their own OLED TV displays.

WOLED displays use a mix of blue and orange-yellow OLED emitters to create a white light. That light then passes through a layer of red, green, and blue filters to create the colored subpixels; a fourth, open subpixel lets unfiltered white light through to brighten up the entire image when necessary. These displays have a few formidable advantages—they can produce deep black levels, have blazingly fast switching speeds (10 times that of LCDs), and are thin and flexible. Future applications of OLED panels could take almost any form factor; they can stretch, bend, fold, roll, stick like wallpaper, or be transparent.

However, against these strengths must be weighed some sobering weaknesses. WOLED isn't a very energy-efficient technology. To date, only about 10 percent of the electric current that runs a blue OLED gets converted into photons that come out of the display. The figure for the orange-yellow emitters is a little over 20 percent, which is near the theoretical maximum efficiency. And, even more important, adding color filters further reduces efficiency. The total light loss at the filter can be as much as 75 percent. Consumers might not notice the high power consumption of their TVs—but the light loss also makes for a less-impressive image.

WOLED displays also come up a little short in color reproduction; the broad-spectrum light they produce reduces the purity of the red, green, and blue subpixels, and the white subpixel that boosts bright images tends to wash out their colors.

WOLED-based TVs, particularly their blue emitters, currently face longevity issues. This problem shows up in an image artifact called burn-in, which can occur after only nine months of use in a typical U.S. home.

Finally, OLED displays are still very expensive to produce. A typical OLED device is made up of 25 superthin layers, requiring multiple manufacturing steps that must take place under a high vacuum. That's why a typical 65-inch OLED TV with 4K resolution today sells for about US $3,000, as compared with about $1,000 for an LCD set of similar quality.

That brings us back to quantum dots because, as it turns out, we can use them for something other than to purify backlights: as an emissive display technology.

The first form of emissive quantum-dot displays will be photo-emissive [see “Photo-Emissive QD TV"]. In this scheme, the quantum dots, instead of hiding behind a color filter array, instead replace it and become the subpixels themselves. In this approach, blue LEDs again make up a backlight. The blue subpixels are simply transparent spots in the array; light passes through them mostly unchanged. The green and red subpixels, each made up of quantum dots, absorb energy from the blue light and then emit precise wavelengths of green and red light, respectively. The light doesn't require any filtering.

The best-performing dots today emit light with over 99 percent efficiency. When combined with the efficiency gains that come with removing the filter, these dots can create a picture as much as twice as bright as today's LCDs with twice the efficiency. This display also has a wide viewing angle because the quantum dots sit at the front of the screen and emit light in all directions.

Photo-emissive QD televisions aren't on the market yet. Expect to see mass production start later this year, with widespread availability in 2019.

There are a few reasons why this technology has taken several years to become ready for commercialization. The main issue was stability. Initially, quantum dots weren't very stable in air, so in early photo-enhanced quantum-dot displays they were sealed inside glass tubes. In today's photo-enhanced displays, a protective plastic coating is used over the quantum dots, but the sheet is left unsealed at the edges.

Early quantum-dot displays had another challenge to overcome—they contained the element cadmium, an environmental hazard. Bringing quantum dots made of noncadmium materials up to the color quality of cadmium materials hasn't been easy. The noncadmium and low-cadmium materials we use today still don't have quite the same purity of color, but they are good enough for most display applications.

For photo-emissive displays, the challenges mounted. It took a while to find a way to reliably pattern the dots into subpixels at high resolution. Our company, Nanosys, chose to focus on photolithography first because that is how LCD color filters are made today, and this approach would therefore be minimally disruptive to display manufacturers. That meant, however, that the quantum dots had to be processed in air, not a vacuum, and also had to be rugged enough to remain stable under the various thermal and chemical steps of LCD fabrication.

Finally, they had to operate long enough to meet the expectations of TV purchasers, which is about 10 years of normal use. As of this writing, we have met these challenges.

This architecture created a few challenges for the display makers as well. One critical issue was preventing ambient room light from exciting the dots. Panel makers have come up with proprietary solutions to both these problems.

Photo-emissive quantum-dot technology will make flexible TVs possible. So far, TV manufacturers have focused on adapting traditional LCD manufacturing techniques to quantum dots. But researchers are excited about the possibility of printing QDs onto plastic or other flexible materials. Because QDs are so small and are initially produced in a solution, they very much resemble printing inks. So researchers, including Japanese ink maker DIC Corp., are experimenting with a variety of printing techniques, including inkjet and transfer printing. We expect to see some type of printed displays begin to hit the market in late 2019 or 2020. The materials are essentially ready to go, but display manufacturers are not quite ready to roll out new production processes.

What comes after photo-emissive QD TVs? It may well be an entirely different approach—one that combines quantum dots with micro-LED technology [see “Micro-LED TV With QDs"]. A micro-LED display is quite similar to that of the jumbotron at your local football stadium, in which each subpixel is a red, green, or blue LED. Now imagine the entire display shrunk down to the size of a TV. That's similar to the way an OLED display works, but because micro-LEDs use inorganic materials, they are more reliable. They can also produce brighter images and have a faster response time.

Both Apple and Oculus VR have acquired micro-LED companies and have been working to bring the technology to the mass market, but cost is still an issue. It turns out that it's really hard to get a reasonable manufacturing yield while trying to fit millions of supertiny LED pixels together with near-perfect accuracy.

Photo-emissive QDs can help solve that problem. It's much easier to make a single-color micro-LED display than a three-color one. Display makers could start with a blue-only micro-LED array and then pattern red and green quantum dots on top. This type of micro-LED is likely to come to market within a few years.

Photo-emissive QD TVs will be only one step in the evolution of quantum-dot televisions. Next will come electro-emissive QD TVs.

In this system, quantum dots are stimulated to emit photons by electrons, instead of other photons. Like photo-emissive QDs, they don't need color filters. But, unlike photo-emissive QDs, they also don't need a backlight. Because each subpixel is addressable—it's turned “on" by stimulating it with electrons—the display wastes no energy producing photons in the backlight, many of which are invariably wasted.

Electro-emissive quantum-dot displays have the potential to completely disrupt the display industry over the next decade, potentially providing the thinness and flexibility of OLED displays but with the cost, color, brightness, and reliability benefits of quantum dots [see “Electro-Emissive QD TV"]. They'll be highly efficient and have wide viewing angles with pure colors. They'll also have beautiful black levels: When a color isn't needed, the dot that produces it will be completely off, with no possibility of light leakage. We'll be able to use low-cost printing techniques to produce them, so there's no reason why they should be costly. And because they are made with inorganic materials, rather than all-organic materials, they will have longer lifetimes without a degradation in performance.

Don't expect to see electro-emissive quantum-dot displays in stores in the next couple of years—they're still in the early phases of development. However, they're moving along quickly: Chinese display maker BOE Technology Group Co. demonstrated the technology publicly for the first time in 2017. The first commercial displays using the technology should start rolling out of factories in the next five years.

All of this technological ferment is being driven, in part, by a recent change in display standards. In the past, television standards have restricted just how closely you could match the images you were seeing on the screen with how they appeared in real life. Even the HDTV standard, developed in the 1980s, didn't try to account for all the colors in the natural world. Rather, its creators considered what colors could be produced given the best available phosphor materials that could be used in a cathode-ray tube.

Today's video standards groups are approaching the problem by asking a much more important question: What's the best color experience for the human visual system?

This approach led to BT.2020, an International Telecommunications Union (ITU) standard, recommended in 2012 and then approved in 2015. BT.2020's color palette covers 99.8 percent of the colors reflected by the natural world—that's nearly 60 percent of the spectrum visible to the human eye. It's already been embraced by Blu-ray Disc manufacturers, and NHK (Japan Broadcasting Corp.) has announced that it intends to broadcast the 2020 Summer Olympics in this format.

Televisions built to the HDTV standard can reproduce only 58 percent of the BT.2020 range of colors. LCD-based Ultra HD TVs (without quantum dots) do better, most covering around 70 percent of the colors, while OLED TVs today are up to around 74 percent. Photo-enhanced quantum-dot displays on the market can handle 85 to 90 percent of the color palette specified by the standard. The photo-emissive QD displays under development are at 93.3 percent, and electro-emissive QD technology, at the moment, is at around 90 percent. In plain language, these TVs have the possibility, at least, of being spectacularly more engaging and impressive than even the best OLED televisions available today, and at a lower cost.

As a result of the pull on the standards front and the push by quantum-dot researchers and TV display manufacturers, we are about to see a revolution in television displays. Finally, after years of fantasizing about low-cost, foldable, and rollable TVs and even TVs-as-wallpaper in the home of the future, we are less than a decade away from having those systems on our walls. And with essentially all the colors the eye can see anywhere we want them, we'll be thinking less about how our screens enable us to watch things and more about what we actually want to watch.

This article appears in the March 2018 print issue as “Television's Quantum-Dot Future."

About the Authors

Zhongsheng Luo is the applications engineering director at Nanosys, a quantum-dot technology company in Milpitas, Calif. Jesse Manders is a senior scientist at Nanosys, and Jeff Yurek is director of marketing.

- Quantum Dots + OLED = Your Next TV - IEEE Spectrum ›

- The Day the U.S. TV Industry Died - IEEE Spectrum ›

- Paper-Thin Metasurface Displays Gun for the LCD - IEEE Spectrum ›

- Your Guide to the Newest Nobel Prize: Quantum Dots - IEEE Spectrum ›

- Q-Dot Display Ups the Screen Arms Race—on the Dashboard - IEEE Spectrum ›

In this variation of

In this variation of  This ultrathin

This ultrathin  The quantum dots replace the filters and become the red and green subpixels themselves; the blue backlight excites the dots and creates the blue subpixels.

Advantages: Wide viewing angle • Potential threefold jump in efficiency and brightness over LCDs • Manufacturers can use existing LCD infrastructure

The quantum dots replace the filters and become the red and green subpixels themselves; the blue backlight excites the dots and creates the blue subpixels.

Advantages: Wide viewing angle • Potential threefold jump in efficiency and brightness over LCDs • Manufacturers can use existing LCD infrastructure These quantum dots emit light themselves when an electric current is applied, so no backlight is involved.

Advantages: Perfect viewing angle • Perfect black levels • Potential low-cost manufacturing • Fast refresh rate • Flexible substrates • No filters needed • Long lifetimes

These quantum dots emit light themselves when an electric current is applied, so no backlight is involved.

Advantages: Perfect viewing angle • Perfect black levels • Potential low-cost manufacturing • Fast refresh rate • Flexible substrates • No filters needed • Long lifetimes This variation of micro-LED technology involves an array of microscopic monochrome LEDs, with quantum dots providing color conversion for the red and green subpixels.

Advantages: Perfect viewing angle • No filters needed • Perfect blacks • Brightest technology • Fast refresh rate • Flexible substrates possible

This variation of micro-LED technology involves an array of microscopic monochrome LEDs, with quantum dots providing color conversion for the red and green subpixels.

Advantages: Perfect viewing angle • No filters needed • Perfect blacks • Brightest technology • Fast refresh rate • Flexible substrates possible