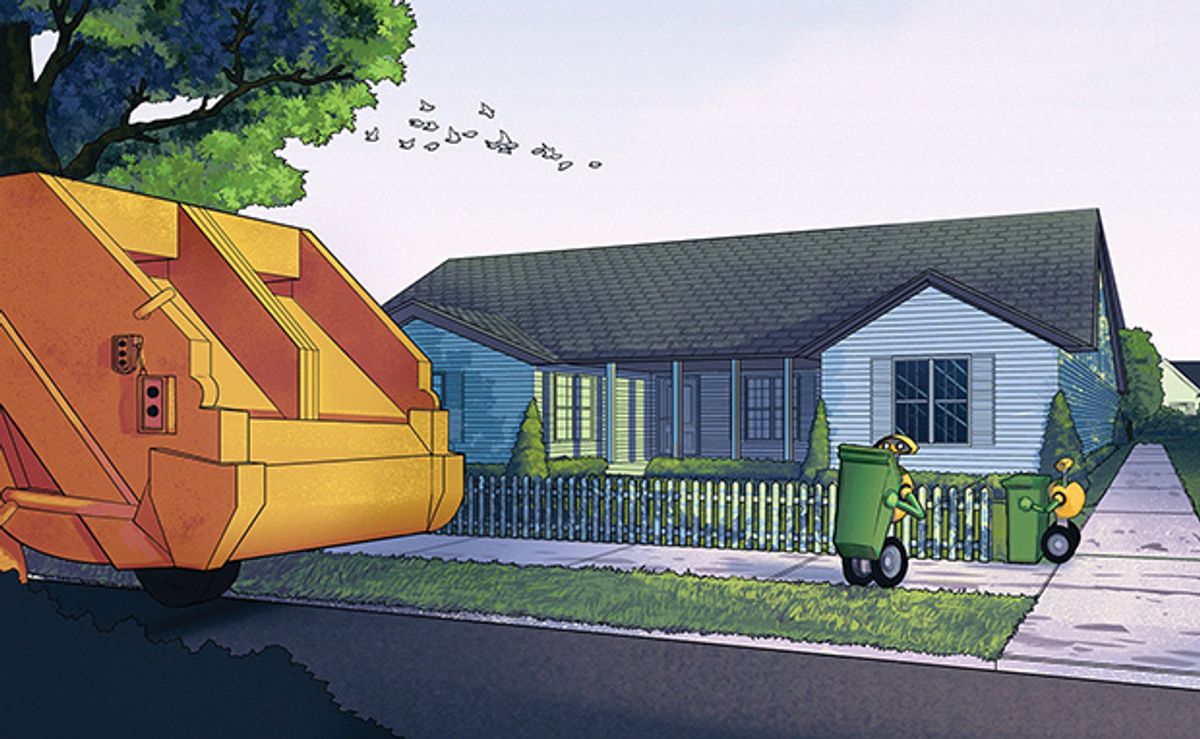

Volvo Group is partnering with Chalmers University of Technology and Mälardalen University in Sweden, Penn State University, and Renova (a Swedish waste recycling company) to “develop a robot that interacts with the refuse truck and its driver to accomplish the work.” The concept image above shows some mobile manipulators capable of lifting heavy loads and dynamically navigating (and balancing) in an unstructured environment.

If Volvo can pull this off, it would be pretty amazing. But at this point, we’ve got two questions: is it something we need, and is it realistic?

Here are all the details:

“The project is called ROAR, for Robot-based Autonomous Refuse handling, and the goal is to introduce a robot that, with the help of instructions from a truck’s operating system, can collect refuse bins in a neighborhood, bring them to a refuse truck and empty them. All of this occurs under the supervision of the refuse truck’s driver, who can thereby avoid heavy lifting.”

Cool! I’m sure we’d all like to see that happen. What I’m not so sure about, though, is why we're not simply trying to improve this technology:

We have this. It works. You only need one human driver, and they don’t even have to get out of the truck. I kind of feel like this is one of those situations where, if you’re Volvo, you can put a substantial amount of effort into designing some mobile manipulator to drive up people’s driveways, find their trash bins, figure out how to grab and (if necessary) lift them, carry them to the truck, dump them, and then put them back where they belong. Or, you can just make sure everyone has standardized trash and recycle bins, ask them to spend 30 extra seconds putting them down by the street, and then just adapt existing technologies to make garbage trucks with those grabby arm thingies completely autonomous. It takes a little bit more work on the part of the humans, but we know this isn’t a crazy thing to ask for because according to YouTube there are lots of communities who already do it.

So what’s Volvo trying to do, exactly? There are certainly some environments where the truck with the arm isn’t going to cut it and mobile robots could be valuable, but it’s going to be a super hard problem to reliably solve. And perhaps that’s part of a point: trying to solve hard problems is a great way to advance the state of the art, and the students at the three universities involved are certainly going to get a lot out of it. The press release says that “this work will continue until June 2016, when the technology will be tested on a vehicle,” and that’s a very agressive timeframe to develop anything like what’s in the concept image above. So we’re not sure what to expect from this, but we’re still excited to see what Volvo and the researchers manage to come up with.

[ Volvo ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.