Your weekly selection of awesome robot videos

Video Friday is your weekly selection of awesome robotics videos, collected by your Automaton bloggers. We’ll also be posting a weekly calendar of upcoming robotics events for the next few months; here’s what we have so far ( send us your events!):

RO-MAN 2021 – August 8-12, 2021 – [Online Event]

DARPA SubT Finals – September 21-23, 2021 – Louisville, KY, USA

WeRobot 2021 – September 23-25, 2021 – Coral Gables, FL, USA

IROS 2021 – September 27-1, 2021 – [Online Event]

ROSCon 2021 – October 21-23, 2021 – New Orleans, LA, USA

Let us know if you have suggestions for next week, and enjoy today’s videos.

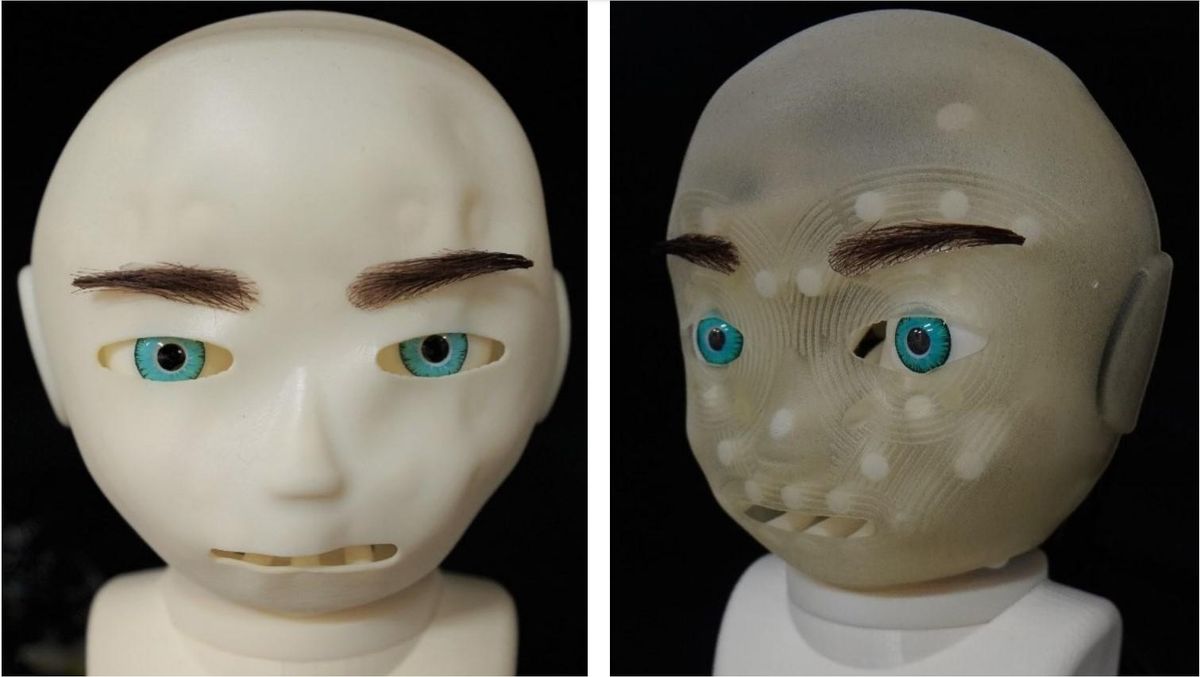

Designing an actuated android face is complicated and time consuming, but Hiroshi Ishiguro’s lab has come up with a system to use a multi-material 3D printer to produce an android head (including skin and mechanical components) all at once. Just shove an actuator pack in the back, and you’re good to go.

With 31 degrees of freedom, the idea is that you’d be able to quickly iterate on designs without having to do a bunch of actuator adjustments at the same time.

[ Paper ]

The OSU Dynamic Robotics Laboratory’s research team, led by Agility Robotics’ Jonathan Hurst, combined expertise from biomechanics and robot controls with new machine learning tools to accomplish something new: train a bipedal robot to run a full 5K on a single battery charge!

In preparation for the previous video, Cassie ran a 5k on a turf field, clocking in a (world record?) time of 43:59.

[

Agility Robotics ]

GITAI’s prototype lunar rover testing regimen is amazing and ridiculous—and definitely watch until the end.

Please do all of this stuff on the moon. Please?

[ GITAI ]

My advice: mute this video and use the following video as a soundtrack starting at about 50 seconds in.

[

ODRI ]

We all know that in theory, a repetitive motion from a fixed position is not all that hard for robots. But there’s a lot of air to cover between the half line and the hoop, right?

[

Toyota ]

Thanks, Harry!

Here’s some super cool research presented at RSS, showing some highly dexterous fingertips made of tiny delta robots.

[

Project Page ]

If you missed the drone show at the Olympics opening ceremony, it was sufficiently impressive, with 1824 drones in attendance.

I’m pretty sure I saw at least one drone falling out of the sky, though.

[ NBC ]

The question with UBTECH’s Walker X is whether it’s going to be another ASIMO (cool to watch but doesn’t do much), or something that’s, you know, useful.

[

UBTECH ]

We usually think of telepresence as one operator and one robot, but the efficient thing to do is have a human who can be sometimes in the loop for a bunch of different robots. Here’s a good start.

[

i-BOTICS ]

Thanks, Fan!

This is a little weird, but I like it!

[

Azumi Maekawa ]

Thanks, Fan!

When you’ve got too many drones on your drone.

[

NIMBUS Lab ]

Good to see Relay out there Relaying.

[

Savioke ]

Recently, the European Union funded the project PULSAR (Prototype of an Ultra Large Structure Assembly Robot) through the Space Robotic Technologies program within Horizon 2020. PULSAR aims to develop and demonstrate the technology that will allow on-orbit precise assembly of a segmented mirror using an autonomous robotic system.

[

Pulsar ]

I will once again point out that if a kitchen robot can’t do prep or cleanup, I don’t consider it to be all that useful.

[

Moley ]

Pro tip: You can always tell when someone is trying to sell something to the military when it has generic hard rock as its soundtrack.

[

Lockheed Martin ]

In episode seven of The Robot Brains Podcast, our guest is ABB’s Marc Segura. Marc is the Managing Director of consumer segments and service robotics at ABB. In this clip Marc explains the differences between Boston Dynamics’ and ABB’s robots.

[

Robot Brains ]

I’d suggest skipping through the vast majority of this domino robot video, but the bits where they actually talk about the mechanical stuff are interesting.

[

YouTube ]

Spot, Boston Dynamics quadrupedal robot product, can reliably walk nearly anywhere a human can, but what does it do? While legged mobility is a necessary skill for many use cases, it’s not the only requirement for valuable producing applications. This talk will focus on the work we have done to develop Spot for remote and autonomous sensing applications: i) Encapsulating Spot’s mobility in an extensible API, ii) Building an autonomous capability, iii) Making it easy to add sensing to build value producing solutions.

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.