Of the more than US $1 trillion each year the United States spends on energy each year, about US $100 billion is wasted as heat energy that might be recoverable with the right technology. Now a new study finds that microscopic pillars built into thermoelectric materials could dramatically boost the conversion of heat into electricity to recycle that energy that would otherwise be lost.

Thermoelectric materials can either consume electricity to extract heat or absorb heat to generate electricity. This makes them capable of solid-state refrigeration and power generation, which require neither moving parts nor chemical reactions.

“Cooling applications are currently the leading commercial applications of thermoelectric devices,” says study co-senior author Kris Bertness, a semiconductor physicist at the National Institute of Standards and Technology in Boulder, Colo. “The form factor and material composition of these devices makes them a good match for cooling hot spots in computer chips.”

The U.S. Department of Energy estimates that 20 to 50 percent of the energy that industry alone uses is lost as heat. Because of that, thermoelectric devices may also help “reuse a significant amount of the energy that gets wasted every year,” Bertness says. “It’s exciting to imagine an impact like that.”

Theoretically, thermoelectric materials work best if they are both bad thermal conductors and good electrical conductors. Bad thermal conductors can support a large temperature difference between two regions to drive a current. Good electrical conductors can, of course, help electricity flow.

However, bad thermal conductors are generally bad electrical conductors, and vice versa. The efficiency of thermoelectric materials in commercial devices is only about 3 to 6 percent, which significantly impedes their widespread use as potential replacements for conventional refrigeration and power generation.

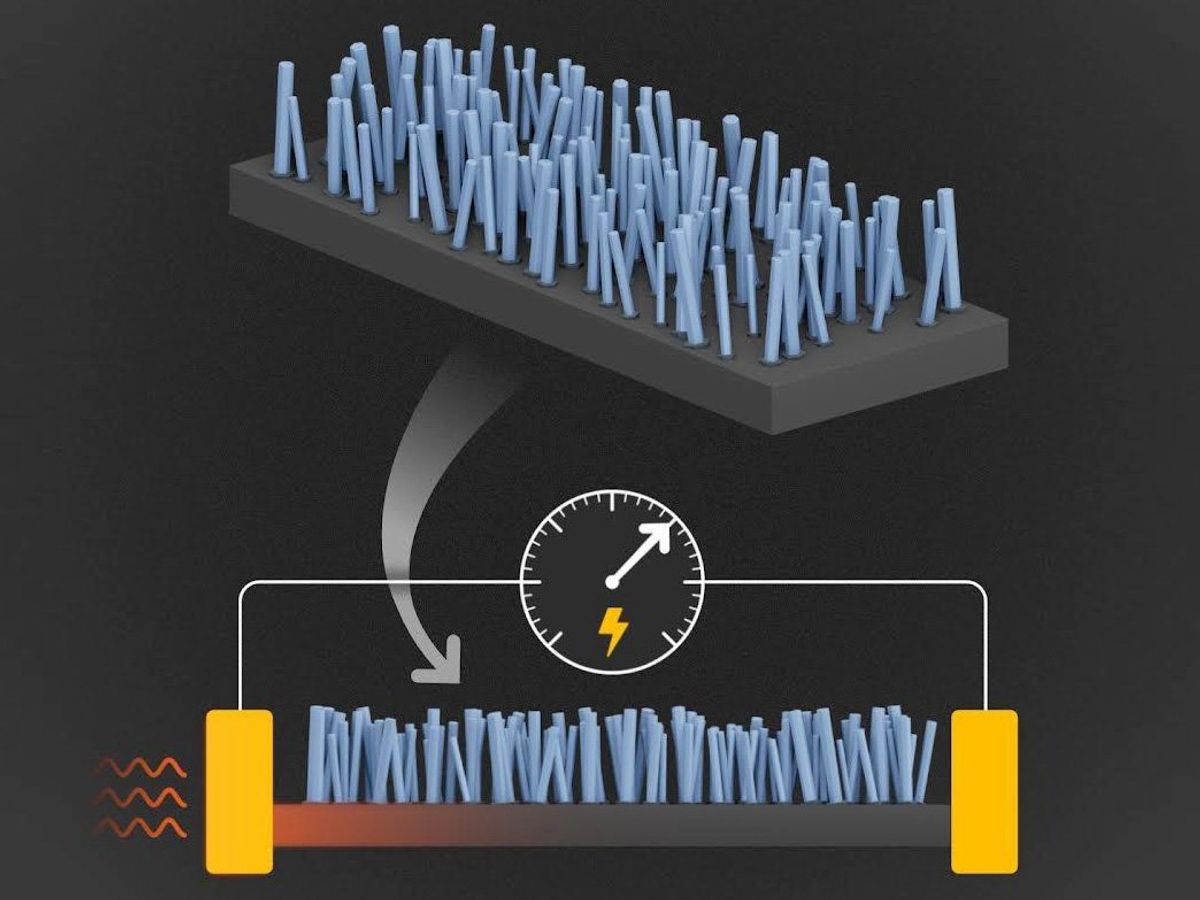

Now scientists have for the first time decoupled the link between thermal and electrical conductivity in a material—specifically, a membrane covered with tiny pillars thinner than a wavelength of visible light.

In the new study, the researchers deposited hundreds of thousands of columns of gallium nitride 50 to 130 nanometers wide and 770 to 5,700 nm tall on top of a silicon wafer. The researchers next removed layers of silicon from the wafer’s underside until a thin sheet about 200 nm thick remained.

This new material is designed to manipulate atomic vibrations—heat, in other words. In solid materials, these vibrations travel as quasiparticles known as phonons.

Both the nanopillars and the silicon membrane host phonons. However, the phonons in the nanopillars are standing waves, pinned by the walls of the columns much the way a vibrating guitar string is held fixed at both ends. This makes it difficult for phonons traveling in the silicon membrane to flow, study co-senior author Mahmoud Hussein, a structural dynamicist and materials physicist at the University of Colorado at Boulder, and his colleagues found.

All in all, the scientists discovered that their new design reduced the material’s overall thermal conductivity by 21 percent while leaving its electrical conductivity unchanged. This reduction in thermal conductivity may have doubled the efficiency at which silicon converts heat to electricity. “We are introducing a new design principle for thermoelectric materials,” Bertness says.

However, “silicon is a terrible material to choose for a thermoelectric device,” Bertness says. The reduction in thermal conductivity may have only improved silicon’s thermoelectric conversion efficiency from 0.16 percent to 0.3 percent, she notes.

The research team’s models do suggest that their new strategy could reduce thermal conductivity by more than 99 percent. This in turn could lead to thermoelectric conversion efficiencies of about 18 percent, Bertness says.

The scientists note that the effect they saw does not result from the nanopillars acting like cooling fins on a heat sink, Bertness says. The gaps between the columns in their samples are too small to permit air to form cooling convective cells.

The researchers are now working on structures made entirely of silicon to simplify the design, and aim to explore the performance of materials other than silicon in the future. In addition, they are investigating other geometries with potentially even better results, such as membranes with etched surfaces, Bertness says.

The scientists will first target cooling applications for their prototype thermoelectric devices, Bertness says. Still, they would also like to generate power from waste heat.

“We can now consider many other materials for thermoelectric devices, and those materials, like the silicon we used in our experiment, are more abundant and less expensive than conventional thermoelectric materials,” Bertness says.

The researchers detailed their findings online 10 May in the journal Advanced Materials.

9 June 2023 Update: The story was revised to clarify that the $100 billion equivalent of energy wasted per year in the U.S. only represents the portion that is estimated to be recoverable.

- Stretchy Devices Spin Electricity From Body Heat - IEEE Spectrum ›

- A Thermoelectric Generator That Runs on Exhaust Fumes - IEEE ... ›

- Thermoelectric Heating Comes In From the Cold - IEEE Spectrum ›

- IoT Devices Could Tap Ambient Heat for Power - IEEE Spectrum ›

Charles Q. Choi is a science reporter who contributes regularly to IEEE Spectrum. He has written for Scientific American, The New York Times, Wired, and Science, among others.