The lust for untested technological fixes is the curse of energy policy. Take your pick: self-driving solar-powered cars, inherently safe nuclear minireactors, or genetically enhanced photosynthesis.

Why not start with what is proven? Why not simply reduce the demand for energy, beginning with residential and commercial buildings?

In the United States that sector accounts for about 40 percent of total primary energy consumption (transportation is a distant second at 28 percent). Even now heating and air-conditioning account for half of residential consumption, which is why the single best thing we could do for the energy budget is to keep the heat in (or out) with better insulation.

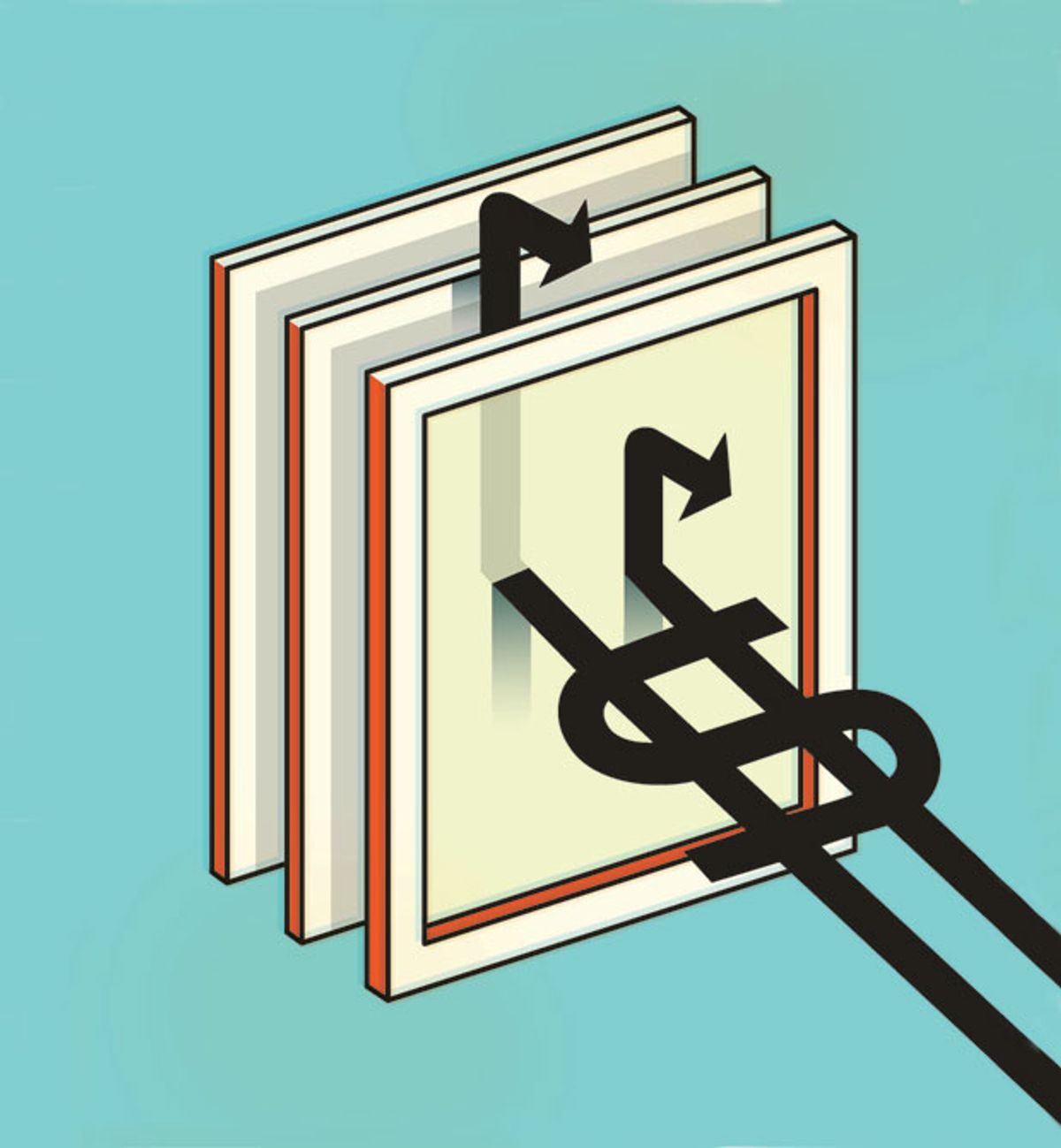

The most rewarding place to do that is in windows, where the energy loss is the highest. That is to say, it has the highest thermal transmittance, measured in watts passing through a square meter of material, divided by the difference in temperature in kelvins on either side. A single pane has a heat transfer coefficient of 5.7 to 6 watts per square meter per kelvin; a double pane separated by 6 millimeters has a coefficient of 3.3. Applying coatings to minimize the passage of ultraviolet and infrared radiation lowers it to between 1.8 and 2.2, and filling the space between the panes with argon chops it to 1.1. Do that with triple-glazed windows and you drop to between 0.6 and 0.7. Substitute krypton for argon and you can get it down to 0.5.

That’s a reduction of up to 90 percent. In the world of energy savings there are no other opportunities of that magnitude applicable on a scale of billions of units. Bonus point: It would actually work.

And there is also a comfort factor: With the outdoor temperature at –18 °C and the indoor temperature at 21 °C, the internal surface temperature of a single-pane window is just around 1 °C, an older double-pane window will register 11 °C, and the best triple-glazed window 18 °C. At that temperature, you can sit right next to it.

And triple windows have the added advantage of keeping out noise and reducing condensation. They are common in Sweden and Norway, but even in Canada windows must meet the standard that is equivalent to just a double-glazed window with one low-emissivity coating.

Cold-weather countries have had a long time to learn about insulation. Not so in the warmer places, which need it now that air-conditioning is becoming widespread. Most notably, in rural China and rural India, single panes are still the norm. Of course, the temperature differential for hot-weather cooling is not as large as in higher latitudes for heating. For instance, at my home, in Manitoba, Canada, the average lows in January are –25 °C, enough to make a difference of 40 °C even when the thermostat is turned down for the night. On the other hand, air-conditioning in many hot and humid regions runs for much longer periods than does heating in Canada or Sweden.

Physics is indisputable, but economics rules. Although triple-glazed windows may cost just 15 percent more than double panes, their payback times are obviously longer, and it is commonly claimed that the step from double to triple design is not justified. That may be so if you ignore comfort, condensation, noise, and above all, the fact that triple panes will keep reducing energy use for decades to come.

Why, then, do visionaries want to pour money into arcane conversion technologies that may not even work and, even if they did, would likely have bad side effects on the environment? What’s wrong with simple insulation?

This article originally appeared in print as “The Visionary Energy Solution: Triple Windows.”