You’re probably swimming in Bluetooth radio signals right now. But none of those are coming from the smallest, lowest-power end of the Internet of Things. These battery-powered and energy-harvesting millimeter-scale sensors are meant to last for years without needing replacement, but their radios can’t muster the energy needed to communicate using even the lowest energy version of Bluetooth, called Bluetooth Low Energy (BLE).

Engineers at the University of Michigan have now built the first millimeter-scale stand-alone device that speaks BLE. Consuming just 0.6 milliwatts during transmission, it would broadcast for 11 years using a typical 5.8-millimeter coin battery. Such a millimeter-scale BLE radio would allow these ant-size sensors to communicate with ordinary equipment, even a smartphone.

The transmitter chip, which debuted last month at IEEE International Solid-State Circuits Conference, had to solve two problems, explains David Wentzloff, the Michigan associate professor who led the research. The first is power consumption, and the second is the size of the antenna. “The size of the antenna is typically physics-based, and you can’t cheat physics,” says Wentzloff. The group’s solution touched on both problems.

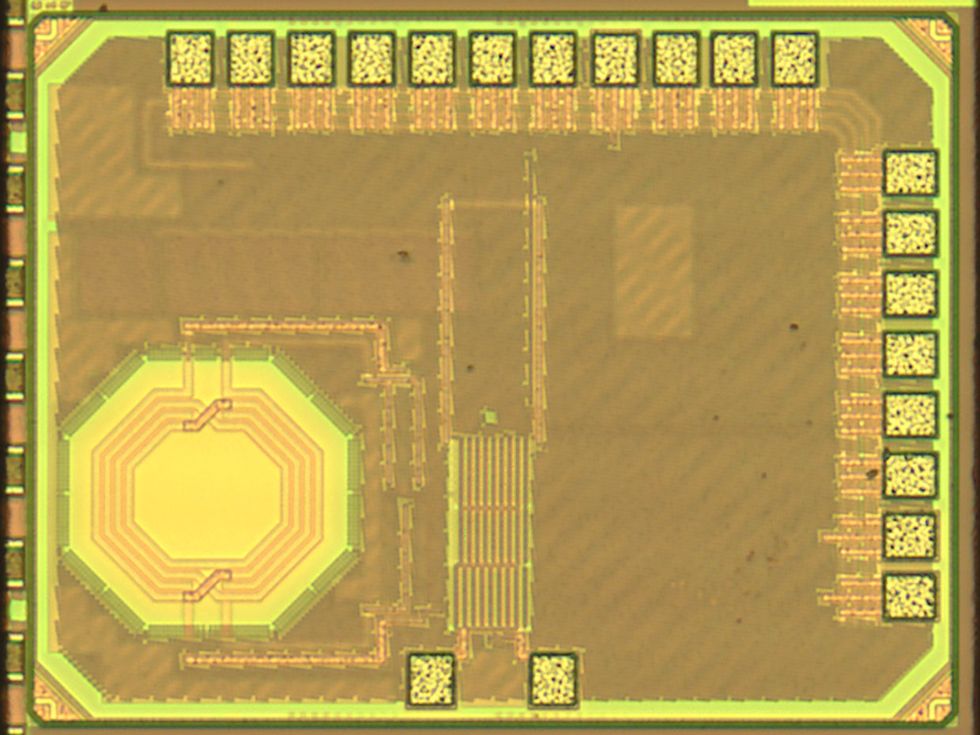

An ordinary transmitter circuit requires a tunable RF oscillator to generate the frequency, a power amplifier to boost its amplitude, and an antenna to radiate the signal. The Michigan team combined the oscillator and the antenna in a way that made the amplifier unnecessary. They called their invention a power oscillator.

The key part of an oscillator is the resonant tank circuit: an inductor and a capacitor. Energy sloshes back and forth between the inductor’s magnetic field and the capacitor’s electric field at a resonant frequency determined by the capacitance and inductance. In the new circuit, the team used the antenna itself as the inductor in the resonant tank. Because it was acting as an inductor, the antenna radiated using a changing magnetic field instead of an electric field; that meant it could be more compact.

However, size wasn’t the only thing. “The big advantage there is that the antenna is a much higher quality factor inductor than on-chip inductors,” says Wentzloff. Quality factor, or Q, is a dimensionless quantity that basically says how efficient your resonator is. As a 14-mm long loop of conductor, the antenna was considerably larger than an on-chip inductor for a millimeter-scale radio could be. That led to a Q that was about five times what an on-chip inductor would deliver.

Though it was a much more efficient solution, in order to meet BLE specifications, the team needed a better way to power the power oscillator. Their solution was to build an on-chip transformer into the circuit that supplies power to it. The transformer looks like two nested coils. One coil is attached to the supply voltage end of the oscillator circuit, and the other is attached to the ground side. Pumping the transformer at a frequency twice that of the power amplifier wound up efficiently boosting the flow of power to the antenna, says Wentzloff.

The new transmitter was tested by broadcasting the BLE “advertising” packet—a set of bits that tell receiving devices that the transmitter is out there. “If you wanted to make a millimeter-scale tracker device, this is all you’d need,” says Wentzloff. But the advertising packet also has a payload section of up to 31 bytes, which is perfect for packing with sensor data.

The research was part of the University of Michigan’s M3 project, which is developing modular, millimeter-scale sensors. The next step, says Wentzloff, is integrating the BLE radio into one of these sensors. “We have multiple radios we use in the M3 project,” he says. “BLE would be another option in that modular platform.”

Samuel K. Moore is the senior editor at IEEE Spectrum in charge of semiconductors coverage. An IEEE member, he has a bachelor's degree in biomedical engineering from Brown University and a master's degree in journalism from New York University.

![The Bluetooth transmitter chip [lavender, right] is connected to a magnetic monopole antenna [green, far right], which acts as an integral part of the transmitter's resonator circuit.](https://spectrum.ieee.org/media-library/the-bluetooth-transmitter-chip-lavender-right-is-connected-to-a-magnetic-monopole-antenna-green-far-right-which-acts-as-a.jpg?id=25588253&width=1200&height=721)