There is such a thing as the “IKEA effect,” which, according to one description, suggests that “when individuals construct products themselves, they tend to overvalue their (often mediocre) creations.” The “IKEA effect” highlights the importance of “self-agency”: when you make something yourself, the work it takes to make that thing gives you a richer sense of initiative and ownership. The result is you get a more positive perception of your creation (even if it’s made of particle board).

Now two researchers from Pennsylvania State University’s Media Effects Research Laboratory want to find out if the same thing applies to robots. The researchers, Yuan Sun and S. Shyam Sundar, say previous studies in human-computer interaction have demonstrated that the “self-agency” effect is present in things as basic as customizing the interface of a software application, resulting in “more positive attitudes toward the technology, a heightened sense of control and identity, greater user engagement, and product attachment.” If the same is true of robots, how can we leverage it to make them more acceptable to people? Sun and Sundar did a series of experiments and presented the results at the ACM/IEEE International Conference on Human-Robot Interaction in New Zealand earlier this year.

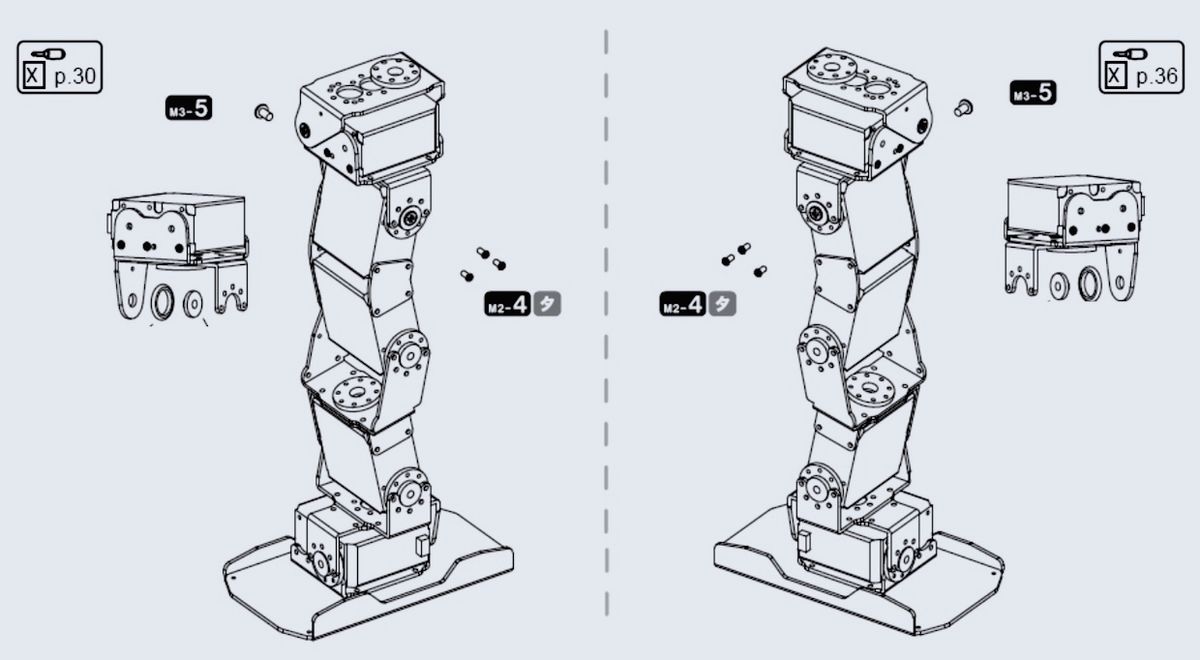

The researchers recruited 80 undergrads to participate in a robot assembly study. The goal was determining how their perception of the robot changed depending on what they were told about the robot in advance, and how much they participated in the assembly of the robot. One group of undergrads were given a robot (a Kumotek KT-X Gladiator humanoid) that they had to equip with a battery, plug into a computer, and run through a simple software setup process, while the other group watched an experimenter go through the same steps. After setup, both groups got to interact with the robot for 5 to 10 minutes. Afterwards, all the undergrads filled out a survey full of questions about sense of ownership, sense of accomplishment, and how they felt about the setup process, and here are the results:

The results of the study clearly demonstrated that robot users hold higher sense of self-agency when they set up a robot by themselves, which generated more positive evaluations to the robot and the interaction process. As with self-assembling furniture and self-designing products, building a robot also seem to have generated a positive “I designed it myself” effect. The perceived sense of ownership is a significant determinant, which in the absence of actual or legal ownership, could lead to an increase in valuation of the robot. By setting up a robot and familiarizing oneself with the robots’ inner workings rather than simply interacting with a pre-assembled robot, individuals indeed get the feeling that the robot is “mine,” thereby cueing the “own-ness heuristic” (that which I own is good), and leading to positive consequences for evaluations of the quality of the robot as well as its interaction with users.

This kind of thing works as long as the assembly process isn’t long enough or difficult enough that users start to get frustrated, but when it works, it works very well: “The sense of agency derived from self-assembly is so strong that the intended purpose or function of the robot does not seem to affect its outcomes,” the researchers write.

Overall, the study suggests that even if you can sell your robot as fully assembled and ready to go right out of the box, people will like your robot better (and think that it’s a better robot) if you let them participate in the setup process, and perhaps let them do a little bit of simple customization:

A few simple final steps in assembling the robot can imbue agency among users. The bulk of the robot assembly could be done by the manufacturer, leaving a few superficial parts for the user to assemble—perhaps aspects that are customizable for individual user, to make it their own. This activity, by itself, can imbue agency among users and lead to positive robot evaluations, as long as the assembly is not onerous.

The researchers say that continuing this ability to tinker over the life of the robot could potentially lead to a stronger and more fulfilling relationship by periodically refreshing that sense of agency, while also helping the robot adapt to the evolving needs of the user. What this study doesn’t address is how long these feelings persist—how long the sense of agency lasts, and how often it might need to be reestablished, but that’s something the researchers hope to explore in a future study.

“Psychological Importance of Human Agency: How Self-Assembly Affects User Experience of Robots,” by Yuan Sun and S. Shyam Sundar from Penn State University, was presented in March at HRI 2016.

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.