Intel Finds Moore’s Law’s Next Step at 10 Nanometers

In 2017, the company will exploit its manufacturing edge to create a new generation of chips

These days, forecasts about the future of Moore’s Law tend to look quite gloomy. But Intel’s outlook—at least for the next few years—is decidedly bright.

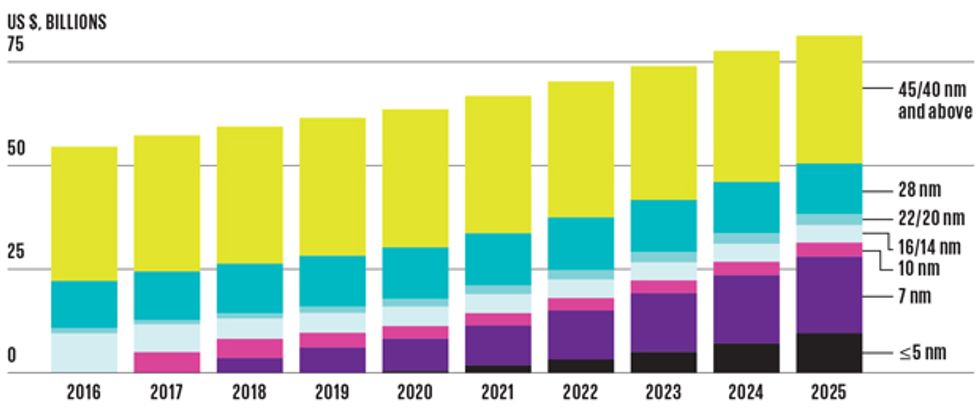

Sometime in 2017, Intel will ship the first processors built using the company’s new, 10-nanometer chip-manufacturing technology. Intel says transistors produced in this way will be cheaper than those that came before, continuing the decades-long trend at the heart of Moore’s Law—and contradicting widespread talk that transistor-production costs have already sunk as low as they will go. In the coming years, Intel plans to make further improvements to the design of these transistors. And, for the first time, the company will optimize its manufacturing technology to accommodate other companies that wish to use Intel’s facilities to produce chips based on ARM architecture, which is nearly ubiquitous in modern mobile processors.

Arm on the Rise

Although it wasn’t always the case, today there is little about the name of a chip-manufacturing generation, or “node,” that aligns with the dimension of any particular feature on a chip. But the transistors on Intel’s 10-nm generation will still be denser than those on today’s 14-nm chips—as well as other companies’ 10-nm offerings, says Intel senior fellow Mark Bohr. Intel has released few figures to date on the dimensions of the new generation. But both the length of transistor gates, which turn transistors on and off, and the distance from one gate to the next—a figure known as gate pitch—will be smaller this time around. The minimum gate pitch will go from 70 nm to 54 nm. And logic cells—transistor combinations used to perform standard logic functions—can be less than 46 percent the size of those built on 14-nm technology.

This is a more aggressive level of miniaturization than in years past, says Bohr, and it helps counteract a recent trend: a slower cadence to the introduction of new chip-manufacturing generations. “One important message is that this node, and the products that we’ll be making on it, will hopefully dispute some of the concerns of the industry that Moore’s Law is slowing down,” Bohr says.

Even though the cost of producing a wafer full of chips will be higher at 10 nm than at 14, Intel says the cost per transistor will be lower. The 10-nm chips are also expected to deliver improvements to switching speed and energy consumption. As has been the case for years already, clock speed isn’t liable to increase, though. “It’s really power reduction or energy efficiency that’s the primary goal on these new generations, besides or in addition to transistor cost reduction,” Bohr says. Improved compactness and efficiency will make it more attractive to add more cores to server chips and more execution units onto GPUs, he says.

In the past, Intel upgraded its transistors once every couple of years, with the introduction of a new manufacturing generation. But at 14 nm, the company offered what might be called a deminode: a set of improvements to its 14-nm transistors before the debut of 10 nm. At 10 nm, the company aims to introduce two of these deminodes (10 nm+ and 10 nm++) before it introduces its next manufacturing generation at 7 nm. This is in part a reaction to the increasing challenges in moving to the next chip generation, Bohr says: “If it’s going to take you longer to [get to] the 10-nm or to the 7-nm generation, then the next best thing to do is to find ways to enhance what you have today and keep delivering better products every year.”

Samsung and TSMC are also making 10-nm chips; in October, Samsung announced that it is the first to reach mass production, with devices bearing its 10-nm chips launching in early 2017. GlobalFoundries is opting to go straight to 7 nm beginning in 2018. All are aggressively pushing the limits of miniaturization, says Dan Hutcheson, CEO of VLSI Research, a firm that analyzes developments in the semiconductor industry. “Everybody’s making these leaps,” Hutcheson says. But they are not marching entirely in lockstep: If you compare 10-nm offerings, he says, “Intel is still about a couple of years ahead” in terms of feature size.

In addition, Hutcheson says, Intel is distinguished from other chipmakers by the control and uniformity of its manufacturing process. This could offer the company a significant advantage when it comes to its foundry services, which use Intel production lines to fabricate chips for other companies.

Manufacturing chips for others is a new approach for Intel. And adding the ability to manufacture ARM processors is an important step. “If you don’t have ARM,” says Hutcheson, “it’s really hard to be a foundry, because it is the standard architecture.”

Intel says the first 10-nm chip to ship will be one of its own processors, with chips for others to follow, but perhaps not until 2018.

This article appears in the January 2017 print issue as “Moore’s Law’s Next Step: 10 Nanometers.”