Ever wanted to send secret information just by passing along an ordinary-looking object? That’s the premise of Microsoft Research’s new project, InfraStructs, which pioneers techniques for concealing identifiers inside 3-D-printed objects. Anyone with a 3-D printer can fabricate an object with coded air pockets, or voids. And then anyone with a terahertz scanner can decode the tag hidden in the object—whether it’s a shape, a line of binary, or a gray code. It’s the modern microdot.

Microsoft presented the scheme at Siggraph 2013, the 40th International Conference and Exhibition on Computer Graphics and Interactive Techniques, sponsored by the Association for Computing Machinery, on 25 July. IEEE Spectrum’s Davey Alba had Andy Wilson, a principal researcher at Microsoft Research who studies human-computer interaction, explain how InfraStructs works.

Transcript:

Davey Alba: Welcome to the Full Spectrum. I’m Davey Alba for IEEE Spectrum. We’re here today with Andy Wilson from Microsoft Research. He’s here to tell us about InfraStructs, a research project that pioneers techniques for reading hidden information in objects. InfraStructs lets you embed binary codes, 3-D watermarks, and geometric shapes into 3-D-printed objects, and then it reads it back with terahertz scanning. Andy, welcome.

Andy Wilson: Hi, how’s it going? Thanks for having me.

Davey Alba: Thanks so much for joining us. So, what exactly is InfraStructs and how does it work?

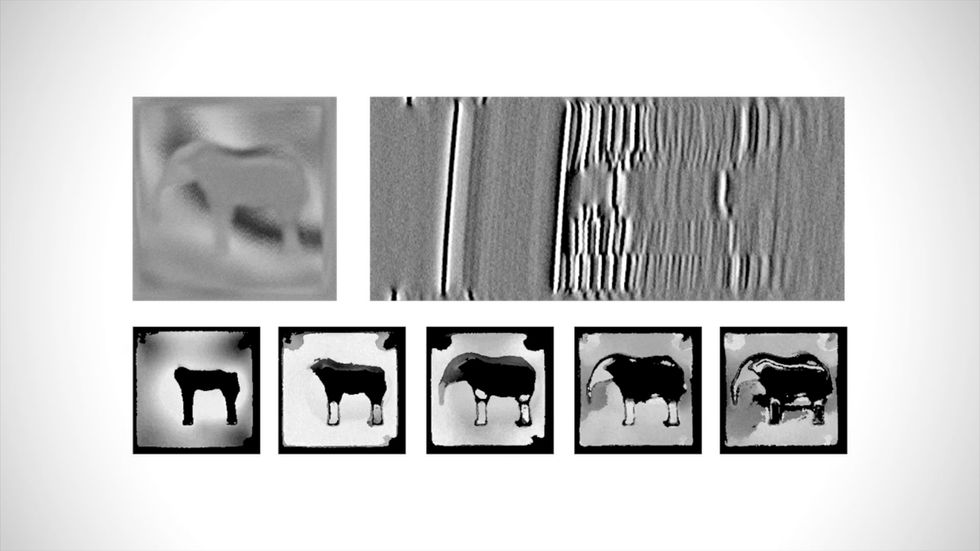

Andy Wilson: So there’re all different kinds of imaging technology we’re interested in. This is some work where we’ve investigated terahertz imaging. So we put the 3-D printing stuff together with the terahertz-imaging techniques that are out there and combined them in an interesting way to embed patterns within 3-D-printed objects. People are studying various techniques like object recognition in the field of computer vision. InfraStructs does something rather differently, where we actually make it relatively easy to identify an object by constructing a recognizable pattern underneath the surface.

So you’ve probably also seen techniques in augmented reality, for example, where you actually put a printed code on the surface of an object. So this is a little bit related to that, where we’re looking at different kinds of binary patterns on objects, except that we don’t have to make the object look different here. We actually can hide the pattern underneath the surface and make it part of the structure itself. Another sort of related area would be RFID [radio-frequency identification]. Typically with RFID you need some kind of little circuit embedded in the object, along with an antenna, you know, which requires its own fabrication considerations and manufacturing. And here we don’t need those kinds of special circuitry and antennas. We actually just put the structure in the object, and we rely on the terahertz scanning to recover that. Another application would be embedding what’s called a gray code in the object, and that’s a particular binary pattern, which actually varies over the surface of the object. And when you recover the binary pattern, you then know exactly where you are in the binary pattern.

There are limits to what you can do. We found that the approach works best when we had material and then interfacing with a void or an air pocket within the material, since chiefly what you have is the ability to sense changes in the index of refraction in the material. So the biggest and easiest way to create a change in the index of refraction is to go from the 3-D-printed material to air. And so that gives you a big jump in the index of refraction. That’s the part that—these interfaces reflect very nicely in the terahertz domain.

Davey Alba: So is it possible to combine the different tags that you talked about into one object?

Andy Wilson: Oh, absolutely. You could certainly construct an object where part of the object has a certain tag scheme and another part has a different tag scheme. One idea is to just print some kind of identifier into the object so that the camera can actually look at some part of the structure underneath the surface of the object and identify it very quickly.

Davey Alba: So what exactly inspired you to do this work? Why 3-D printing?

Andy Wilson: So this work was pursued by Karl Willis, who was an intern. In trying to figure out what to do, what kind of projects would interest both of us, we both came to this particular combination of his interests in 3-D printing and mine in sensing.

Davey Alba: What sorts of challenges did you run into while you were developing this project? And can you expand on some of those, give us examples?

Andy Wilson: Well, so there’s a couple of interesting challenges. One is just in understanding the limits of the technology. So we, Karl and I, put together a bunch of prototypes that just tried to test the limits of what you could sense with terahertz imaging. So that involved building very specialized little objects that looked at—varied the angle for example, that the beam would hit the objects. So we performed a number of different tests like this, which weren’t especially useful but then allowed us to perform some examination later, processing of the scans to determine that yes, you could get away with—you could see a surface that was up to, I think, about 15 degrees away from the camera. So that was the first thing, sort of establishing the performance of the device. And then that led us into designing the actual patterns themselves, starting to figure out what kinds of structures you can at first fabricate with a 3-D printer, or a laser cutter, or other kinds of digital fabrication techniques. And then in concert with that, to be able to write computer programs that can efficiently and reliably recover those patterns. So that was definitely one of the more challenging aspects of the work.

Davey Alba: So this technology kind of lends itself—actually this was one of our first thoughts—to sci-fi sort of spying applications, passing secret messages, using objects where you embed these messages in these seemingly innocent-looking objects. Can you say anything to that?

Andy Wilson: Well the thing of it is, it has to—it’s a little tricky because that message has to be there at the time the object is created. You can’t just sort of tuck it into an existing object. I’m really reminded, now that I think about it, of some of the stuff that Craig Venter’s company is doing where they, you know, assembling DNA strings and then putting a copyright message in there or encoding other kinds of data into DNA. I think that’s the kind of thing you can do kind of invisibly, I guess. Is that sci-fi? It seems to me like all this stuff is like, you know, not too far off.

Davey Alba: Great. Thanks so much for your time, Andy.

Andy Wilson: Thanks! Thank you so much.

Davey Alba: We’ve been talking to Andy Wilson from Microsoft Research about the InfraStructs project. For IEEE Spectrum, I’m Davey Alba.