Chip designers would love to use light beams rather than copper wires to move data between microprocessors. Such optical interconnects would overcome the bandwidth bottleneck inherent in the wires and take full advantage of the leaps in processor speed, but marrying two very different technologies—electronics and photonics—has been a high hurdle to overcome.

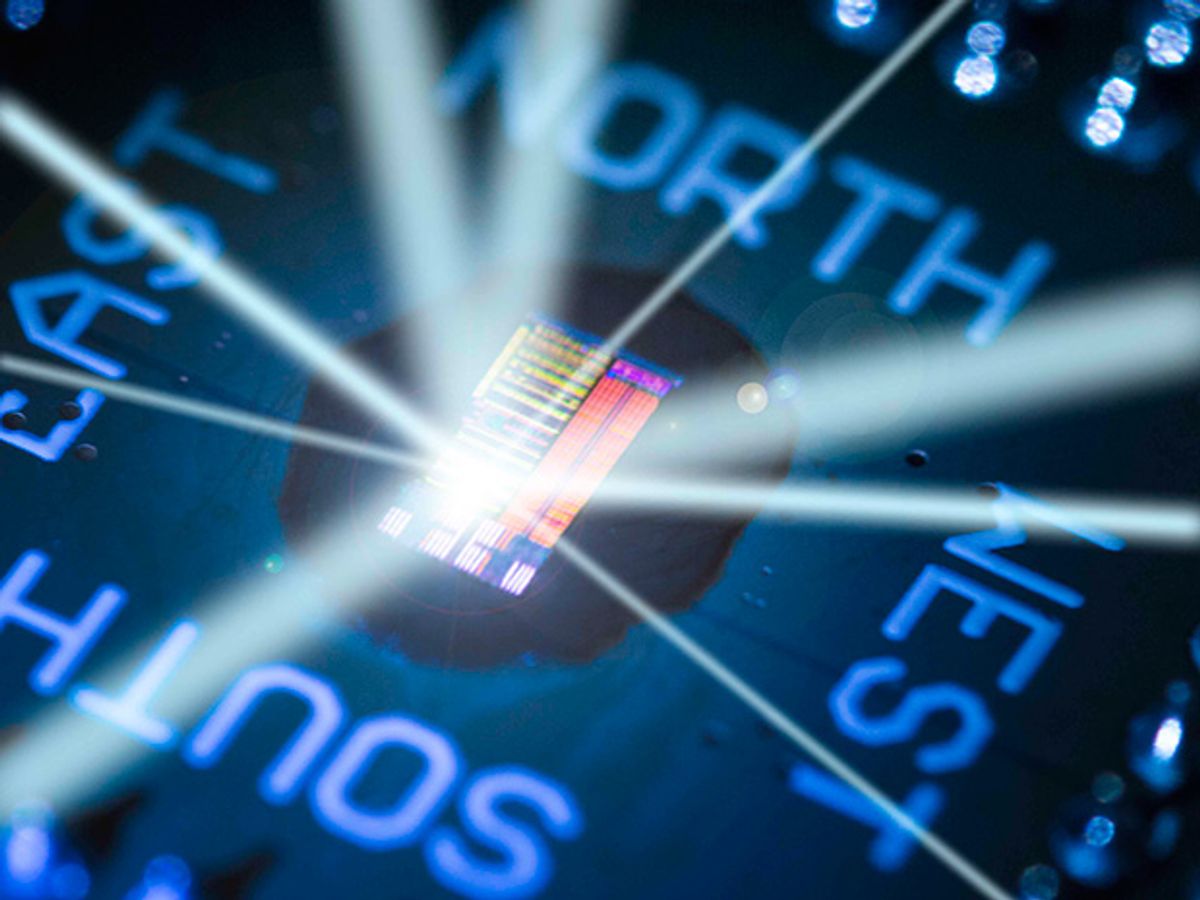

Now a group of researchers has proposed a way to build transistors and optics on the same chip, doing so for the first time without a major overhaul of the chip-making process. And they used it to build an IC containing 70 million transistors and 850 photonic components, which together provide all the logic, memory, and interconnection functions a processor needs.

Engineers at MIT, the University of California, Berkeley, and the University of Colorado, Boulder founded a start-up to commercialize what they call their “zero-change” approach to chip-making. It relies on the standard CMOS processes used to make today’s computer chips—specifically a high-performance process for the so-called 45-nanometer node, which debuted in 2007. “We didn’t make any changes to the process,” says Chen Sun, lead author of a paper on the process that appears in this week’s issue of Nature. .

They started with a silicon substrate, then added a 200-nm thick layer of silicon-oxide, which acts as an insulator. Over that is the active layer—100 nm of crystalline silicon—plus a 100-nm layer of nitrides and a dielectric coating. The crystalline silicon includes a small amount of germanium to produce strain on the silicon and speed up the circuits.

“We are able to use those existing layers to make our processors,” Sun says. The processor they constructed was a dual-core RISC-V architecture—an open instruction set architecture originally developed at Berkeley. It also included 1 megabyte of SRAM memory.

One key component to the photonics portion of the chip is a micro-ring resonator, a loop 10 micrometers across that’s coupled to a waveguide. They dope the structure with the same elements used to make p-n junctions in the transistors, and that action creates a notch filter, which passes all incoming light but a single wavelength. Putting a negative voltage across the junction pushes the charge carriers out of the ring, while a positive voltage returns them, creating a modulator that imprints digital signals on the light beam.

The micro-ring also lets the photodetector work. Normally, a photodetector made of the SiGe in the chip would have to be many millimeters to a centimeter long in order to have a chance of absorbing enough photons to actually detect the light. With the micro-ring resonator, the light passes through so many times that the SiGe can absorb it.

Micro-ring resonators have existed for a while, but “a lot of people in industry kind of ignored them,” says Sun. That’s because as they heat up, the index of refraction shifts and they drift away from the desired wavelength. The team developed active thermal stabilization to overcome this. The stabilization system includes a separate photodetector and a digital controller. When the detector notices a change in the amount of photocurrent coming to it, the controller alters the voltage across the micro-ring, which changes how much heat it dissipates.

Another aspect of the design requires etching away some of the silicon substrate. Because the oxide layer is so thin, the light passes through it to the substrate, which carries it away. Removing the substrate reduces that loss. However, the team leaves the silicon in place under the microprocessor and memory, where no light is coming out anyway, so they can attach a heat sink. The lack of silicon also allows them to deliver light from an external laser to power the optical components, even though the chip is bonded face down to the printed circuit board.

Sun says his startup company, Ayar Labs, hopes to be able to commercialize the technology within a couple of years, but at least one expert is skeptical. Anthony Levi, a professor of electrical engineering and physics in the Photonics Center at the University of Southern California, says the engineers involved in the optoelectronic processor are to be congratulated for making a working chip that integrates photonics and electronics, but he doubts the approach is practical. “The challenges of silicon photonics remain the same as they have always been: this includes too much optical loss, too much power dissipation, too much chip area, and so on,” Levi says.

He says the federal Defense Advanced Projects Research Agency, which funded the work, has poured “massive amounts of precious research money” into silicon photonics, but that the industry and customers, whose decisions come down to cost, haven’t bought into it. “Even if the technology worked, there has to be a compelling reason to adopt a new and disruptive approach to building systems,” Levi says.

Neil Savage is a freelance science and technology writer based in Lowell, Mass., and a frequent contributor to IEEE Spectrum. His topics of interest include photonics, physics, computing, materials science, and semiconductors. His most recent article, “Tiny Satellites Could Distribute Quantum Keys,” describes an experiment in which cryptographic keys were distributed from satellites released from the International Space Station. He serves on the steering committee of New England Science Writers.