Researchers at the University of Liverpool in the UK have demonstrated the ability to manipulate a material so that it has both magnetic and electrical polarization, a feature that could lead to low-power electrical writing of information with non-destructive magnetic reading, and logic devices that can operate without charge current flow.

A fair amount of research has gone into exploiting this property of both electrical and magnetic polarization in bismuth ferrite, which has the rare property of possessing a permanent local magnetic field while always possessing an electric polarization that can be switched by applying an electric field.

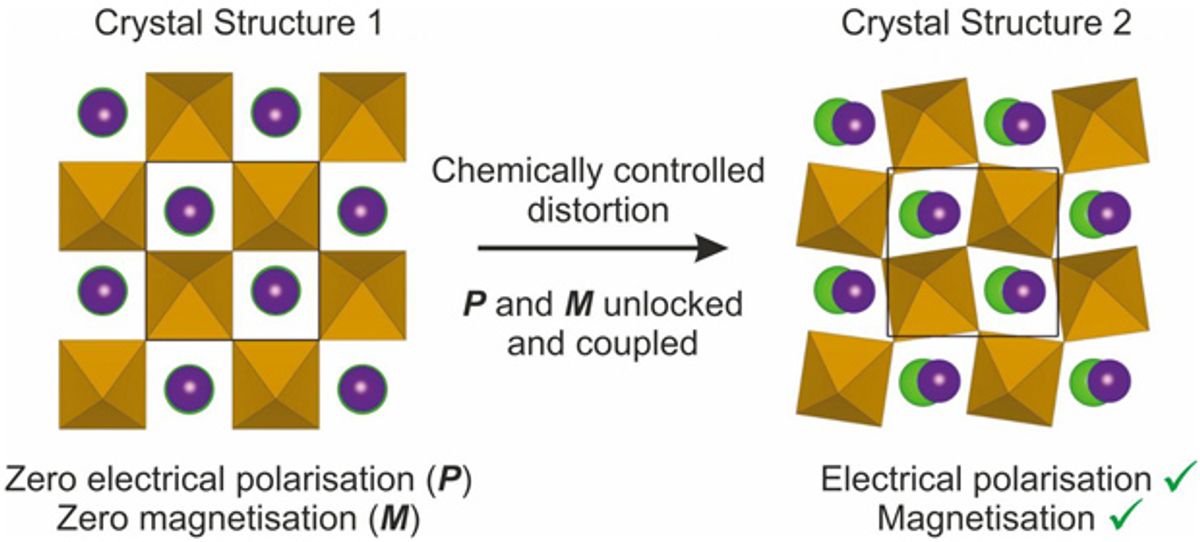

However, in research published in the journal Science, the Liverpool team employed crystal chemistry to engineer specific atomic displacements in a layered perovskite to give it properties it did not previously possess. Perovskites are a class of crystals that have become all the rage, especially in the world of photovoltaics, because of their low cost, high charge-carrier mobility, and long diffusion lengths. In real world terms, this means that the electrons in perovskite-based photovoltaics can travel through thicker solar cells, which absorb more light and thereby generate more electricity than thinner cells.

In these most recent experiments, concern for perovskites’ attractive properties in photovoltaics were set aside so that the perovskite crystal could be engineered to have a novel set of properties.

“By designing in the required atomic-level changes using both computation and experiment together, we produced three properties (polarization, magnetization, magnetoelectricity) from a material that initially displayed none of them,” said Liverpool professor Matthew Rosseinsky, in a press release.

Rosseinsky added: “We were able to demonstrate that the magnetization and polarization are coupled by measuring the linear magnetoelectric coefficient, a key physical quantity for the integration of such materials in a device. This coupling arises because both properties are produced by the same single set atomic motions that we built in to the material.”

While these developments could potentially lead to applications for information storage, the researchers concede that a number of challenges still have to be overcome before making that step, including switching the polarization and making the material more electrically insulating.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.