Researchers at the Georgia Institute of Technology have developed a first of its kind: an optical rectenna, which combines the qualities of an antenna with a rectifier diode. If further refined, the researchers believe the device could lead to a new generation of highly efficient solar cells.

While rectennas have been around since the 1960s, they have not been able to operate at optical wavelengths. The challenge in achieving this goal was to make the antenna portion of the devices small enough as well as fabricating some kind of rectifier into them.

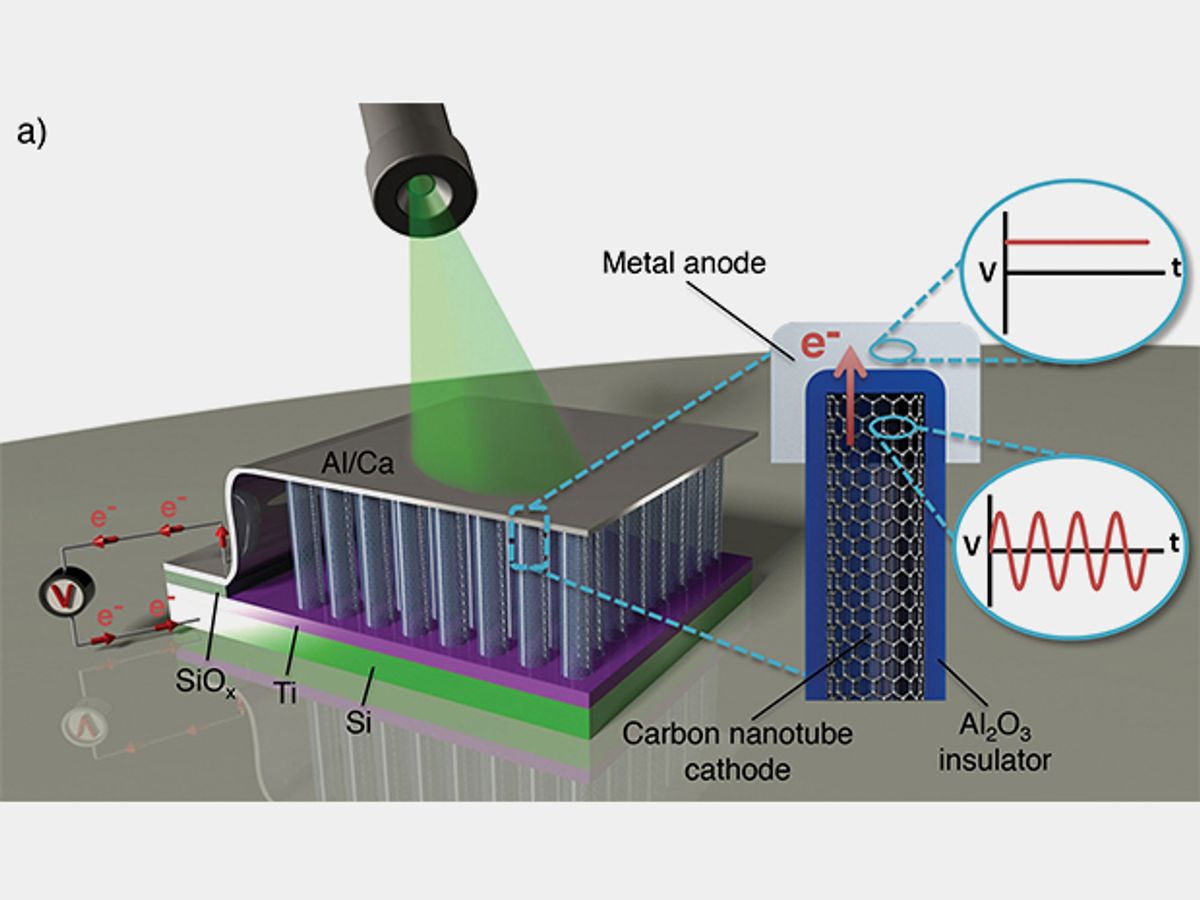

In research published in the journal Nature Nanotechnology, the Georgia Tech researchers were able to overcome this challenge by growing multi-walled carbon nanotubes that serve as antennas for capturing light. In addition, each of the nanotubes has tiny rectifiers built into it that can convert the oscillating charge produced by the waves of light hitting the antennas into a direct current.

“Based on what others have done and what the theory is showing us, I believe that these devices could get to greater than 40 percent efficiency [in solar cells],” said Baratunde Cola, an associate professor at Georgia Tech in a press release. That would be about double today’s best solar cell efficiency.

With an enormous number of carbon nanotubes serving as the antennas, one of these devices can produce a fair amount of current. However, the energy conversion efficiency of these devices is still low at around one percent, which is fine for high-temperature detectors but not so great for a solar cell. Nonetheless, the researchers believe that with some optimization techniques they have up their sleeves, they could produce a device within a year that is commercially viable.

“We could ultimately make solar cells that are twice as efficient at a cost that is ten times lower, and that is to me an opportunity to change the world in a very big way,” said Cola. “As a robust, high-temperature detector, these rectennas could be a completely disruptive technology if we can get to one percent efficiency. If we can get to higher efficiencies, we could apply it to energy conversion technologies and solar energy capture.”

The combination of materials used make the optical rectennas is key to how they function. The researchers first grow metallic multi-walled carbon nanotubes onto a conductive substrate. They then coated the nanotubes with an aluminum oxide material to serve as an insulator using an atomic layer deposition (ALD) process. More than two years ago we saw how ALD fabrication techniques had opened the door for the production nano-antenna arrays for highly efficient solar power devices.

On top of this layer of nanotubes another layer of optically transparent thin films of calcium and aluminum is deposited. The difference in work function between the calcium layer and the carbon nanotubes produces a potential of two electron volts, which is enough to push the electrons out of the nanotube antennas when they are excited by light.

A video describing the devices architecture and function can be seen below.

Cola believes the key to extracting greater efficiency from the devices will involve changing this material mix so that the carbon nanotubes are opened up in such a way as to allow multiple conduction channels, reducing the resistance in the device.

Cola added: “We think we can reduce the resistance by several orders of magnitude just by improving the fabrication of our device structures.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.