For decades, nuclear magnetic resonance (NMR) spectroscopy has been one of the key technologies used to study the atomic structures of complex biological compounds. The most popular technique, solid-state NMR, involves putting the material to be analyzed inside tiny cylindrical rotors which are then spun to high frequencies. The big limitation of solid-state NMR, however, is how fast the rotors can spin before they shatter, which depends on the rotor material’s strength.

Now, researchers from MIT’s Center for Bits and Atoms and the MIT Department of Chemistry found a way to fabricate rotors from a single diamond crystal. These rotors are smaller and stronger than the rotors already in use. They also can be spun at far higher frequencies, resulting in an increase in resolution and a decrease in sample-acquisition time, the study’s authors say. Their research was published in the July 2023 issue of Journal of Magnetic Resonance.

One of the techniques used with solid-state NMR is magic-angle spinning, which provides improved resolution and sensitivity. In this technique, after the cylinder is filled with the material being analyzed, it’s suspended in a magnetic field and spun using jets of (usually) nitrogen gas as it’s subjected to radio-frequency pulses. The cylinder spins at the “magic” angle of exactly 54.74 degrees relative to the applied magnetic field, at which angle it is easiest to get the clearest measurements of atomic structure.

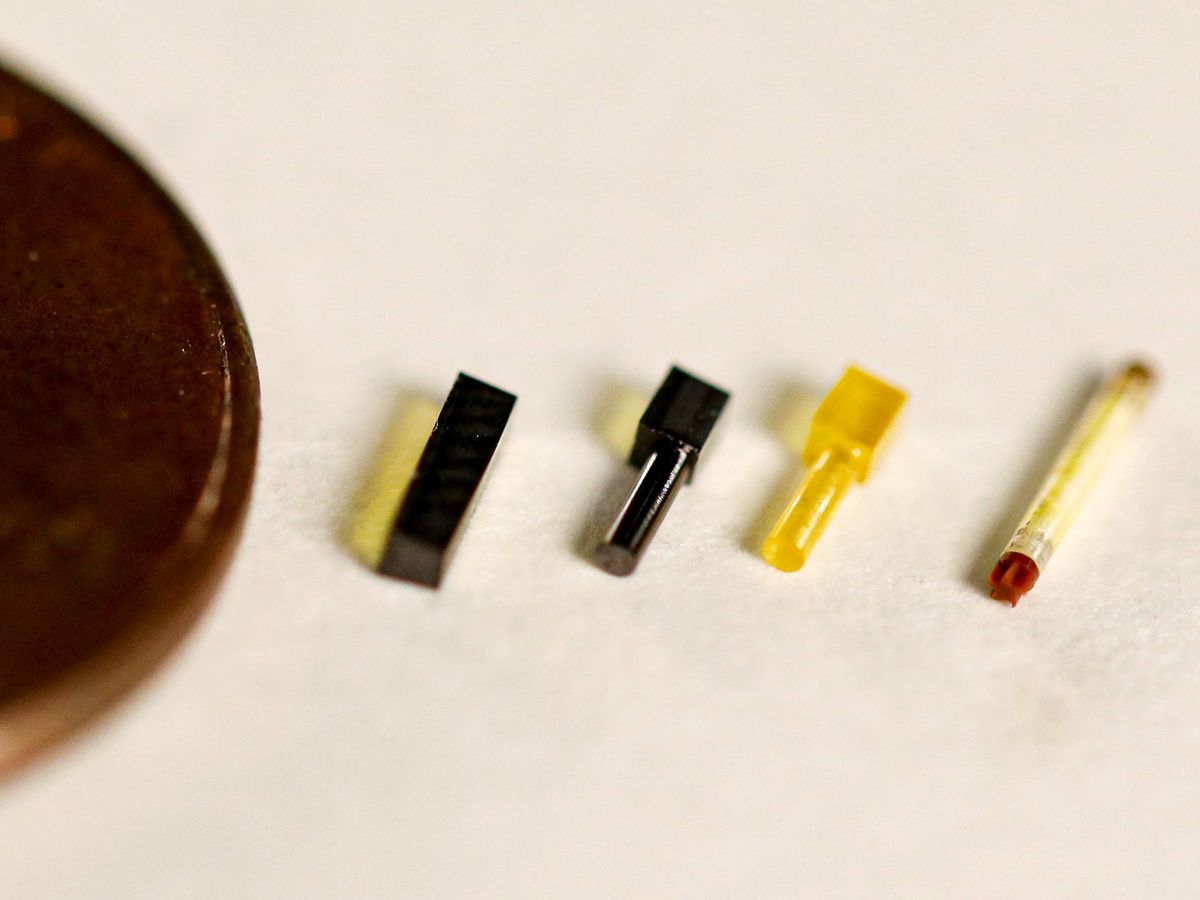

For the past couple of decades, rotors for magic-angle spinning NMR have been made out of yttria-stabilized zirconia (YSZ), a high-performance ceramic material. These rotors, which are as small as 0.7 millimeters in diameter—about the size of a pencil lead, with a hole in the middle for the sample—have a maximum spin speed of about 111 kilohertz, or 7 million rotations per minute. At these speeds, the YSZ rotors tend to fail about half the time—specifically, they explode, along with the sample and the NMR coil. “It’s been the case in solid-state NMR for a very long time,” says Zachary Fredin, one of the paper’s authors, “that any sort of problem, [and] everything disappears and does thousands of dollars of damage.”

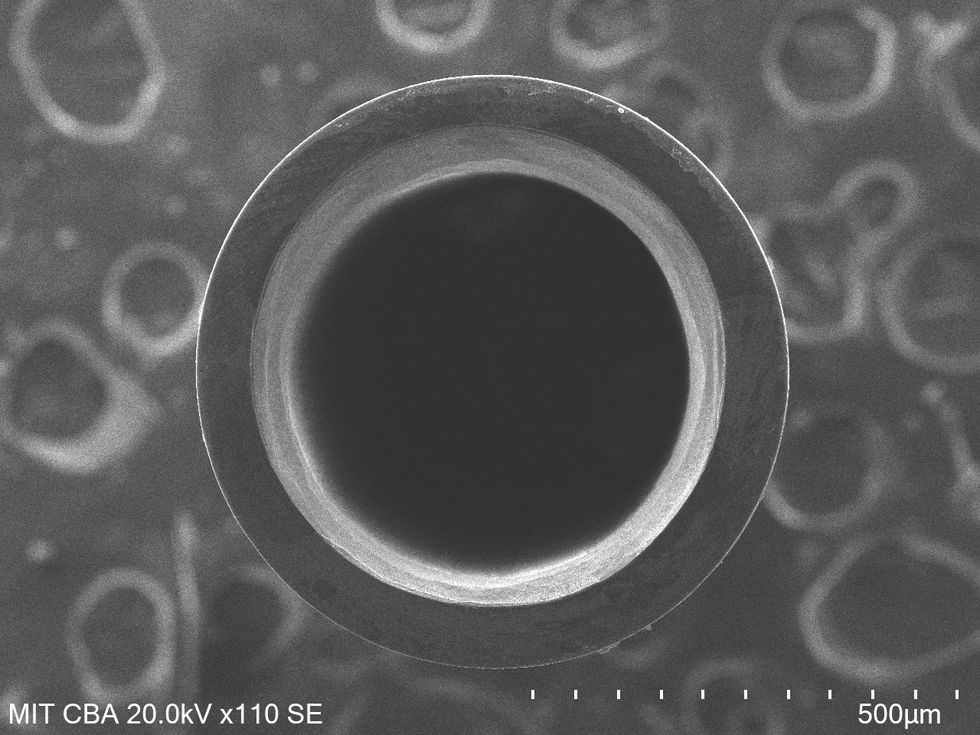

Creating rotors out of single-crystal diamond has been an intriguing option for a while, because not only is diamond very tough, it is also far more permeable to terahertz radiation and has great thermal conductivity. The challenge has always been how to drill high-aspect ratio holes through the diamond crystal. In 2019, a then-student at the Center for Bits and Atoms, Prashant Patil, discovered a method for drilling such holes using laser micromachining. This, Fredin says, was a fairly unexpected outcome

, and it paved the way for crafting diamond rotors for magic-angle spinning NMR.

Like the YSZ rotors, the diamond rotors have a diameter of 0.7 mm, but they can potentially spin much faster. “Theoretically, diamond [rotors] should be good up to three or four times [the speed of YSZ rotors], and we should be able to comfortably spin to 250 or 300 kHz,” says Fredin. In their tests, however, the researchers were able to spin only up to 124 kHz (or 8.5 million RPM), as they were limited by the sonic speed of nitrogen, the drive gas.

“There’s considerable friction in the bearing system, which is the first consideration here,” says Natalie Golota, a graduate student in MIT’s chemistry department and another coauthor. “We don’t want the rotor going faster than the speed of sound, as [at that speed] there is significant turbulence.” Using helium gas could make the spin frequency three times as fast, as helium has a sonic velocity that about three times that of nitrogen.

But as the researchers tested their rotors with a combination of nitrogen and helium, pure helium, and starting with nitrogen and switching to helium, they came up against yet another design limitation. The apertures in the air bearings that support the rotor are designed for nitrogen. “I think our biggest remaining challenge would be that we need to have helium-compatible bearing systems and change the rotor bearing dynamic so that we can actually take advantage of the increased speed of sound of helium gas,” Golota says. This would be a “game changer,” she adds. “A diamond rotor with 100 percent helium gas…can also give us very high resolution data, and a lot of powerful information on the sample.”

The main driving force behind this project—funded by the National Institutes of Health—was to better understand the three-dimensional structure of proteins. “We want to understand, for example, the structure of proteins involved in Alzheimer’s disease, and other amyloid-driven diseases,” Golota says. “But we can also use this to study different viral diseases and membrane protein-based disorders.”

There are also other potential applications, she says, such as in difficult heat-transfer environments, other biological spectroscopies, microelectronic fabrication, and so on. “We’ve gotten very good at having control over very small diamond objects and machining them accurately, so we are definitely still looking into this.”

Payal Dhar (she/they) is a freelance journalist on science, technology, and society. They write about AI, cybersecurity, surveillance, space, online communities, games, and any shiny new technology that catches their eye. You can find and DM Payal on Twitter (@payaldhar).