Researchers at Rensselaer Polytechnic Institute (RPI) have taken a significant step towards transforming high quality 2D graphene sheets into 3D macroscopic structures that could be used for applications such as thermal management for high power electronics, structural composites, flexible and stretchable electrodes for energy storage, sensors, and membranes.

In research published in the journal Science, the RPI researchers developed a new layered structure for graphene that addresses the problem of achieving the mechanical strength of graphene in its 3D form while maintaining its attractive thermal and electrical properties in its 2D form.

“We have developed a new approach in reassembling 2D sheet structures into 3D macroscopic structures with greatly enhanced physical properties,” said Jie Lian, one of the researchers and the lead author in the paper, in an e-mail interview. “The discovery of the highly thermally conductive and mechanically strong fibers using different size graphene sheets is unprecedented for conventional fiber technology.”

The fiber was made with a scalable wet spinning process, according to Lian, and he believes the strategy of using different sized sheet structures can be applied to construct macroscopic structures (papers, fibers, tubes, and fabrics) for other materials with 2D sheet structures.

In previous studies, macroscopic graphene oxide (GO) fibers have been assembled from a dispersion of GO in aqueous media by a simple wet spinning process, with graphene fibers produced upon reduction of the GO fibers. Unfortunately, the reported mechanical strength of graphene fibers produce in this way is relatively low and no thermal properties were evaluated previously, says Lian.

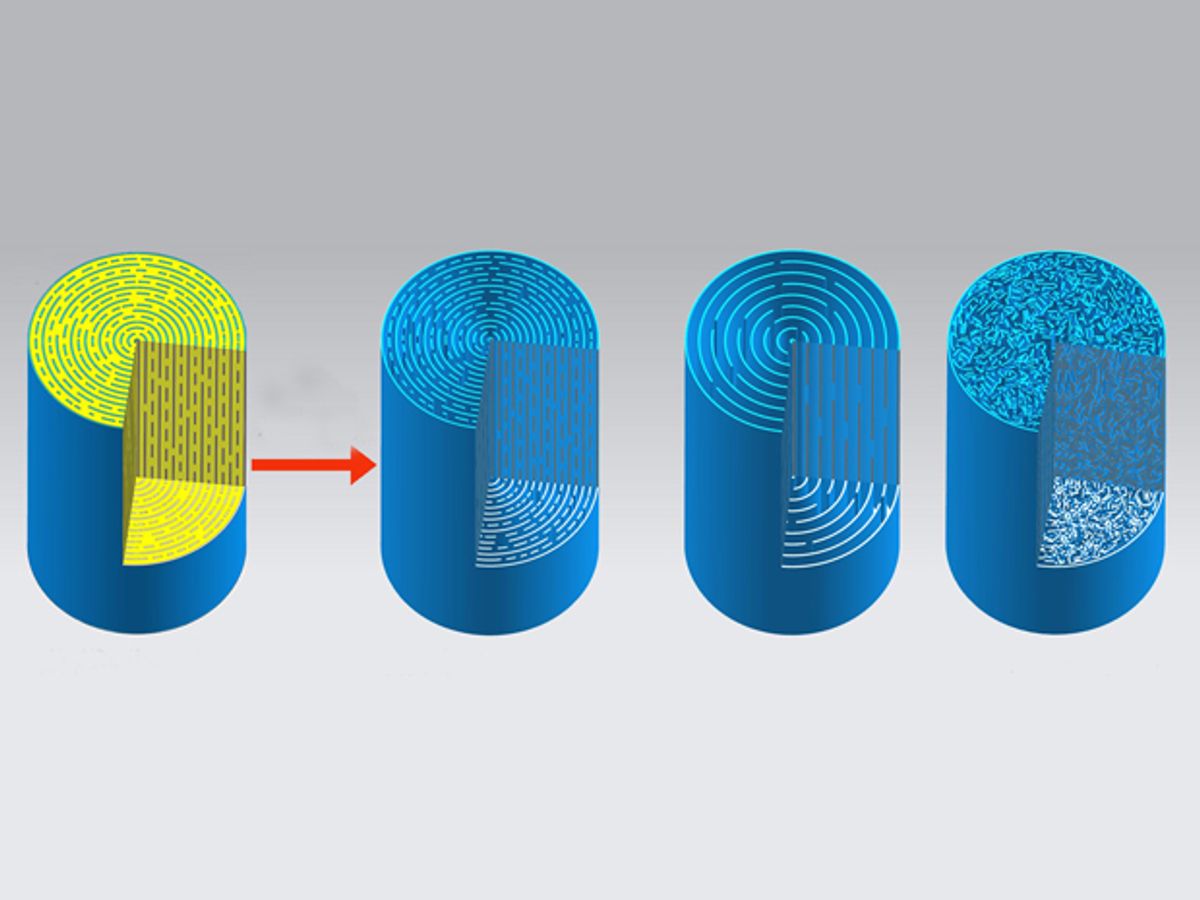

Because un-optimized microstructures and defects in the graphene fibers can significantly affect the thermal-mechanical properties, the RPI team believed that new approaches were needed to improve graphene sheet alignment, compactness and removal of defects and functional groups in order to enhance the physical properties.

The researchers will continue to characterize the inner fiber structure to further understand its properties. But the RPI team envisions perhaps more lofty goals.

“We are also interested in exploring the large-scale manufacturing of graphene fibers by wet spinning process or combining with additive manufacturing for large-scale components,” Lian says. “This should lead us to using graphene fibers in functional textiles for thermal energy storage, thermal management and structural components.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.