Memristors—devices that can “remember” their resistance state after the device is shut off—can serve not only as digital memory but also as building blocks of the neuromorphic computers of the future. However, it’s been challenging to build a device that meets the demands of large-scale manufacturability and cost-effectiveness. One promising avenue takes memristors into two dimensions, using atomically thin layers for faster switching and scalability. Now, researchers at the University of Rochester have figured out how to strain a particular 2D memristor to give it the fastest switching speed and lowest operating energy of any such 2D device.

The resistance inside these memristors is controlled by a phase-changing mechanism. Normal phase-change memory works as follows: A glassy material, usually a chalcogenide, is sandwiched between two contacts. Current passing through the glass can alter its phase between a low-resistance crystalline state and a high-resistance amorphous state. This allows for huge differences in resistivity between the two states, making them attractive for memory devices. But inducing this behavior in thin 2D films causes some issues—defects in the glass may inhibit consistent phase changes and increase the necessary operating voltages.

“Whenever you fabricate these devices, you get stresses and strains built up in the wafer anyway, so you can zero everything out or you could just put it to use, and it actually enhances your device.” —Stephen Wu, University of Rochester

Back in 2019, researchers at Purdue University and the National Institute of Standards and Technology came up with a novel phase-change mechanism that is much more amenable to thin films. They used molybdenum ditelluride, a material in the transition-metal dichalcogenide class capable of arranging itself into a few different phases. For their memristor, the team switched the two-dimensional molybdenum ditelluride film between its semiconducting phase, with high resistance, and its semimetal phase, with low resistance. This turned out to be a much more robust phase change in the compact device, but the required switching voltage was quite high—more than one volt per phase change. And the switching energy was three femtojoules per switch—moderately high for devices of its kind.

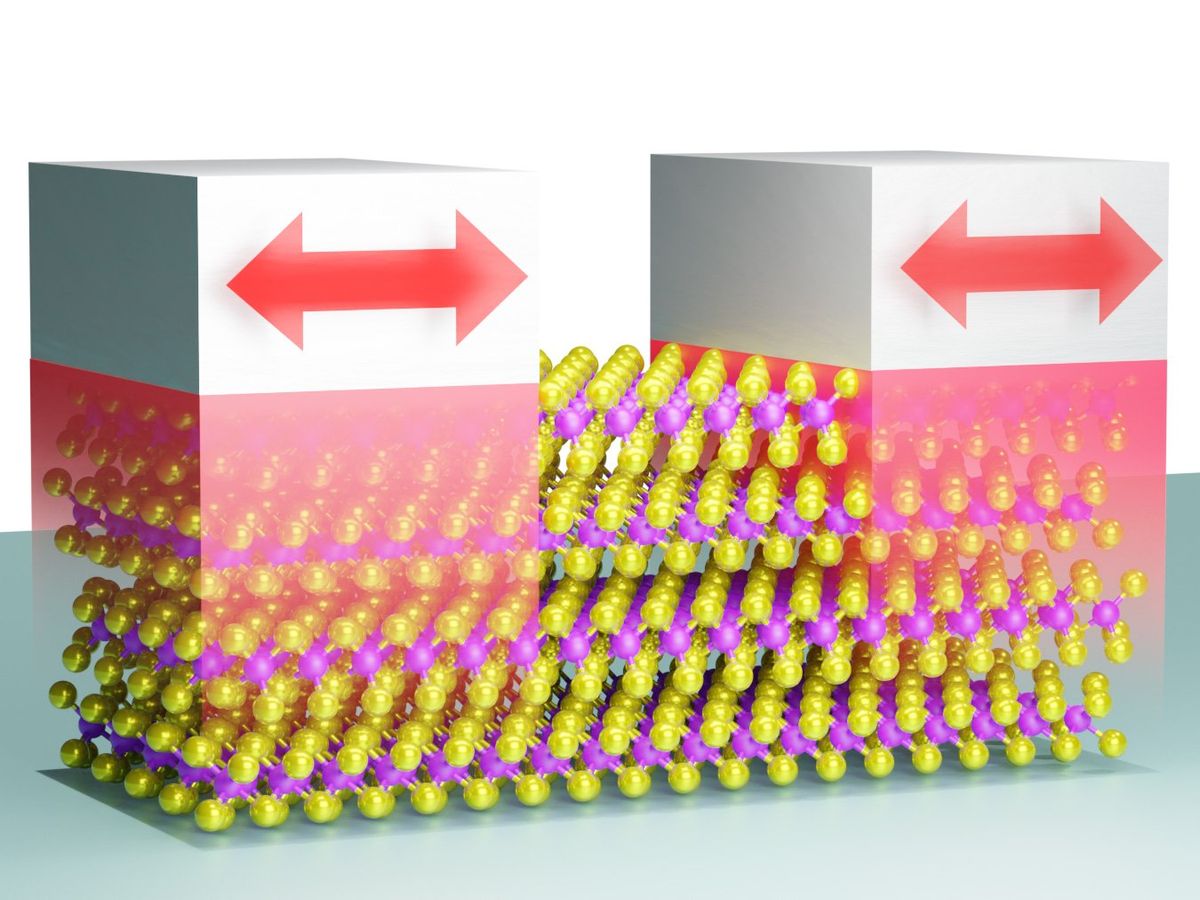

The Rochester team added a controlled amount of strain to the 2D film, forcing it to teeter just on the edge between the two phases. This made both the switching speed and the switching energy orders of magnitude lower—a mere 0.1 volts and 120 attojoules to switch. Plus, the resistance ratio between the two states was 108, the highest for any 2D memristor.

The exciting thing about this approach is that the team is using strain that’s process-engineered. Rather than adding steps to the manufacturing process, they’re using what’s already there to their advantage. The contacts naturally have some stress as they are deposited and patterned. When the device is constructed, the stress from the contacts is released into the molybdenum ditelluride, straining it in two directions at once. By precisely controlling the thickness and angle of the contacts, the team was able to engineer the exact amount and direction of strain that made the device function best.

“Whenever you fabricate these devices,” says Stephen Wu, assistant professor at the University of Rochester and the principal investigator on this result, “you get stresses and strains built up in the wafer anyway, so you can zero everything out or you could just put it to use, and it actually enhances your device.”

Before these devices are ready for prime time, there are several other metrics that need to catch up. This device retains its state for just over a day, and degrades after several hundred switches. The team is working on miniaturizing their memristor, and preliminary results suggest that performance only improves with shrinking, Wu says. They are also looking into retention and robustness. As this is the first demonstration of the device, further engineering is needed. But, Wu says, “these are challenges common to the field, and we may be able to borrow from existing ideas to overcome these roadblocks.”

- The Mysterious Memristor - IEEE Spectrum ›

- Neuronlike Memristors Could Superspeed 6G Wireless - IEEE ... ›

Dina Genkina is an associate editor at IEEE Spectrum focused on computing and hardware. She holds a PhD in atomic physics and lives in Brooklyn.