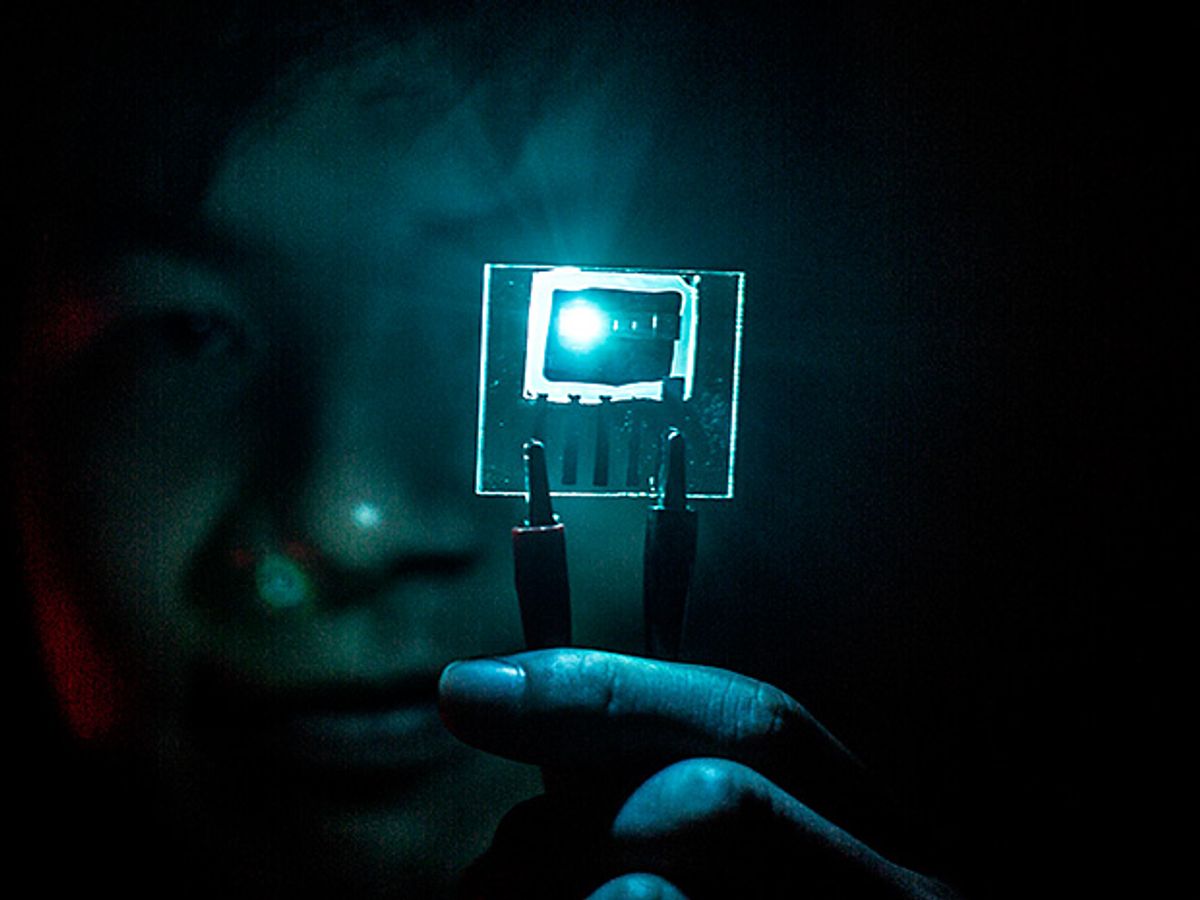

Many displays in smartphones and televisions generate red and green light with phosphorescent organic light-emitting diodes but use more energy-hungry fluorescent devices for blue. That's because blue PHOLEDs only last for a couple of days. Now researchers have found a way to extend the lifetime of blue PHOLEDs by a factor of 10, bringing them much closer to commercial use.

“We moved that 55 hours to 616 hours, which is a pretty big step,” says Stephen Forrest, head of the Optoelectronic Components and Materials group at the University of Michigan in Ann Arbor. “It’s still not really long enough, but it’s getting close.”

The pixels in smartphone displays consist of red, green, and blue OLEDs. But while the red and green phosphorescent OLEDs still retain half their brightness after a million hours of use, the blue fades within hours. Chris Giebink, then a Ph.D. student in Forrest’s lab, proposed an explanation back in 2009. He thought that when the OLED was turned on and the holes and electrons were excited to a higher energy level, these excitons would collide with the phosphor’s molecular bonds and dump their extra energy into them, destroying the molecule.

So instead of trying to build a better phosphorescent molecule, Forrest’s group took an engineering approach to the problem. The semiconductor layer of an OLED is generally doped with phosphors that control the characteristics of the light they emit. Forrest’s team dispersed the dopant material along a gradient, placing different concentrations at different locations. When the phosphor is doped uniformly, Forrest says, the excitons tend to cluster along the edge—increasing the chance of the molecular mayhem of exciton collisions. But with the dopants dispersed along a gradient, collisions are less likely. “We still have the same amount of excitons, but just spread them out spatially,” Forrest says.

Not only does the spreading extend the lifetime of the molecule, it also makes the blue version more efficient than its red and green counterparts, because the excitons are also less likely to collide with each other and waste energy. And Forrest says the results, published in today’s Nature Communications, shows that Giebink was correct about the failure mechanism.

After running at 1000 candela per square centimeter for 616 hours, the team’s blue PHOLED still produces 80 percent of its possible light output. That’s not quite good enough for commercial use, Forrest says, but now that the failure mechanism is understood, it should be possible to improve that by a factor of 100, or even 1000, more than enough to make the device commercially viable.

Neil Savage is a freelance science and technology writer based in Lowell, Mass., and a frequent contributor to IEEE Spectrum. His topics of interest include photonics, physics, computing, materials science, and semiconductors. His most recent article, “Tiny Satellites Could Distribute Quantum Keys,” describes an experiment in which cryptographic keys were distributed from satellites released from the International Space Station. He serves on the steering committee of New England Science Writers.