Printed electronics have opened up applications—flexible circuits and rollable displays, to name two—that were impossible with conventional electronics. Usually, printed electronics are created using organic or metal-oxide inks whose electronic properties often pale in comparison to silicon. Now scientists have discovered a new way to print silicon, potentially ousting its erstwhile usurpers.

The ability to print silicon onto substrates has existed for some time, but producing solid silicon from liquid polysilane ink required exposing the silicon to temperatures upwards of 350 degrees Celsius—far too hot for many of the flexible surfaces onto which one might want to print. The new technique, from Delft University of Technology in the Netherlands and the Japan Advanced Institute of Science and Technology in Ishikawa, completely bypasses this step. The collaborators detailed their findings in the 21 April online edition of the journal Applied Physics Letters.

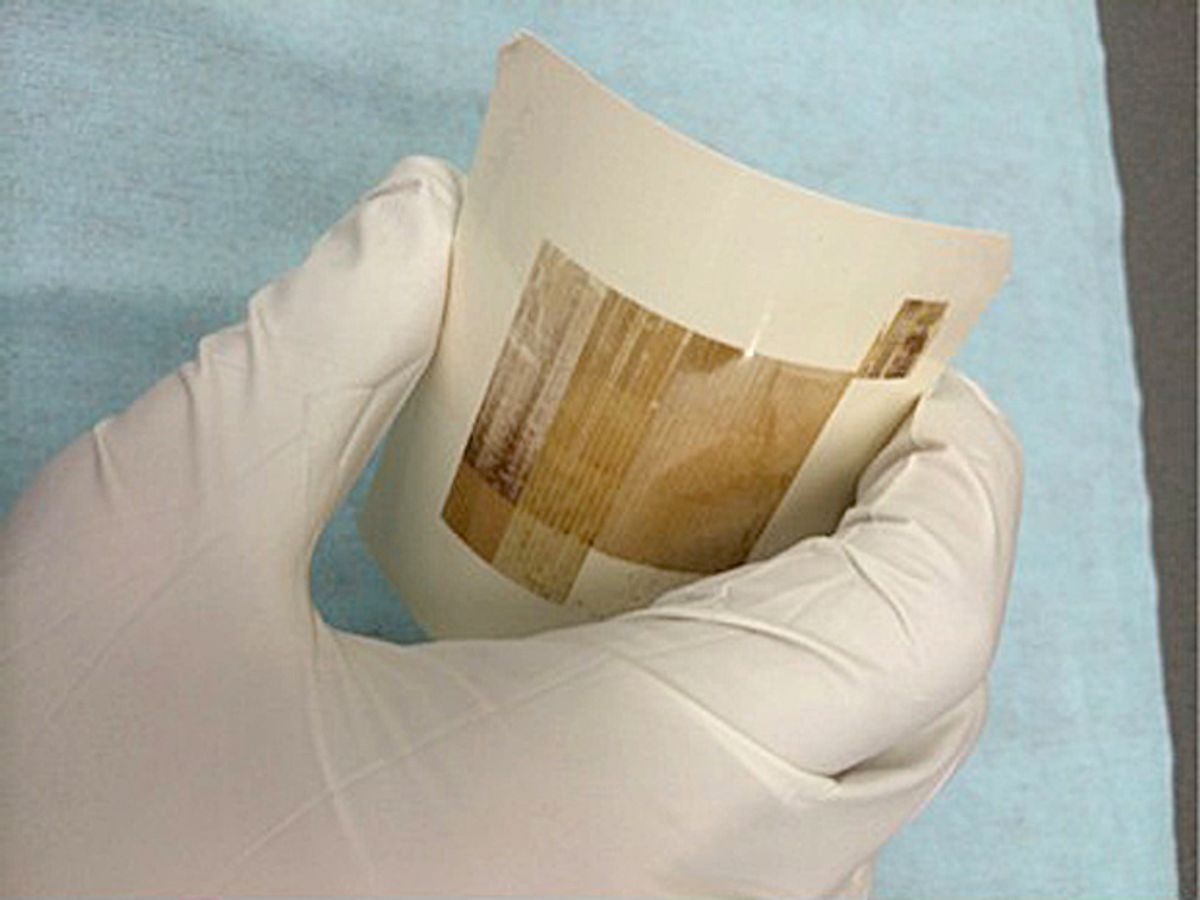

First, the researchers coated paper with liquid polysilane by skimming the fluid onto the surface with a blade in a virtually oxygen-free, water-free environment. They next transformed this ink into polycrystalline silicon with a blast from an excimer laser, a tool commonly used for manufacturing smartphone displays. The laser pulse only lasted a few dozen nanoseconds, leaving the paper completely intact.

The final silicon film, which is about 200 nanometers thick, required “baking” at a maximum temperature of only 150 °C. The researchers found that the thin-film transistors they created using this new strategy performed on par with conventional polysilicon devices and far better than other ink materials.

The researchers say this work could lead to low-cost, high-speed, flexible, biodegradable, recyclable electronics that could show up in wearable electronics, solar cells, RFID tags, edible devices, and trillions of Internet of Things sensor nodes.

Charles Q. Choi is a science reporter who contributes regularly to IEEE Spectrum. He has written for Scientific American, The New York Times, Wired, and Science, among others.