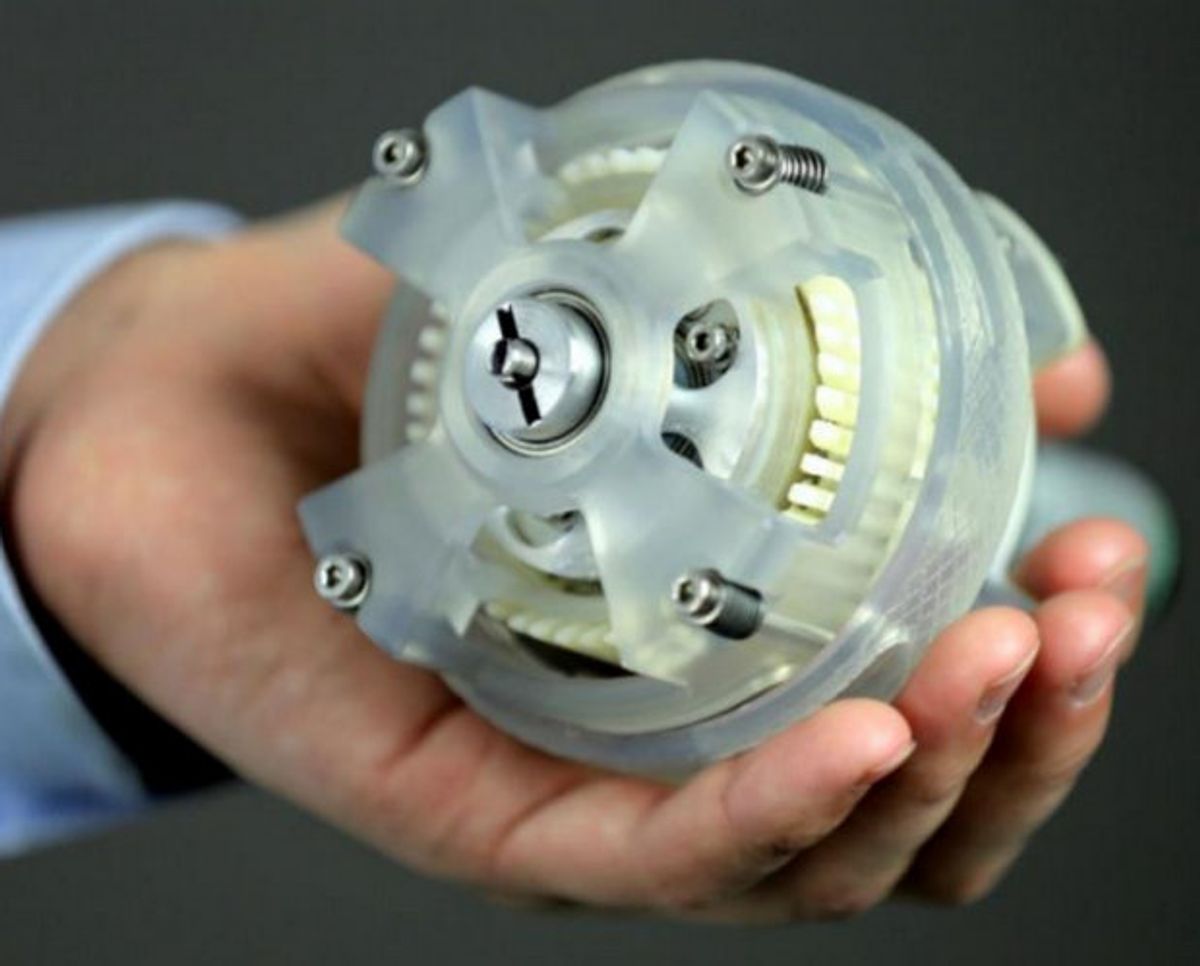

Last year, SRI’s Alexander Kernbaum introduced us to Abacus Drive, a new kind of rotary transmission based on pure rolling motion that promises to be much cheaper and much more energy efficient than harmonic gears, which are the current (and quite expensive) standard. Now Kernbaum is back with another ingenious—and cleverly named—transmission design. It’s called Inception Drive, and he describes it as “an ultra-compact, infinitely variable transmission based on a novel nested-pulley configuration” that’s designed to make robots—and all kinds of other things—safer, more affordable, and vastly more efficient.

In an infinitely variable transmission (IVT), which is a specific kind of continuously variable transmission, the transmission ratio includes a zero point that can be approached from either a positive side or a negative side. In other words, a constant input, like an electric motor turning the same direction at the same speed, can be converted to an output that’s turning faster, turning slower, turning in the opposite direction, or not turning at all (in this “geared neutral” mode, you’d need infinite input revolutions to cause one output revolution, hence the name “infinitely variable transmission”).

IVTs do already exist: The concept is not brand new. What is brand new from SRI is the clever engineering that makes Inception Drive an order of magnitude smaller and lighter than existing IVTs. This is a big deal because it means that IVTs can be integrated into robotic applications in a way that was physically impossible before.

The reason why a transmission like this is important for robotics is primarily because of the efficiency that it enables, as Kernbaum explains in a paper presented at ICRA earlier this year:

It’s not uncommon for a robotic transmission to be less than 50 percent efficient…. When the output speed changes frequently, it is impossible to optimize a motor and fixed-ratio transmission system for size, performance, and efficiency at the same time: The fixed ratio of the transmission causes substantial losses within the motor. For instance, a high-quality electric motor may be 90 percent efficient when operating under high velocity and low torque, but in robotic applications, the system must instead be designed to achieve the needed peak torques and speeds in the smallest package possible, resulting in a system that almost never operates near its peak efficiency.

A variable-ratio transmission can help align the motor velocity with its peak efficiency or peak power, but their size, weight, and complexity have historically precluded their use in most robotic and industrial applications. This is where SRI’s ultra-compact infinitely variable transmission (IVT) can play a key role. Its small size, simplicity, and reversible output enable several new applications for variable-speed transmissions. It is small enough to replace fixed-ratio transmissions in robots, where we believe it can cut the energy consumption of many robotic platforms in half, doubling battery life for mobile platforms.

If you can’t quite understand how it works from the video (and even Kernbaum admits that it’s difficult to visualize), read the explanation we’ve come up with below, and then watch the video again and see if it helps.

There are a few very important things going on here that are very hard to see, because they’re happening inside the drive itself. The first thing is how the two pulleys interact with each other. This happens through the V-belt, of course, but it’s not as though one pulley turns, which turns the belt, which causes the other pulley to turn, as in a conventional transmission. Rather, the outer pulley is fixed and doesn’t turn at all, while the inner pulley, which is nested inside the drive, has a wobble in it, since it’s mounted off-center to the input shaft. (The device’s name is a reference to the movie Inception, but with nested pulleys instead of dreams.)

As the input shaft causes the inner pulley to wobble around in a circular motion, it’s continuously lifting the V-belt off of the outer pulley on its outward wobble, and putting the V-belt back down again when the wobble is inward. If the effective diameters of the inner and outer pulleys are the same, the V-belt will just get transferred back and forth between the two pulleys and not much will happen. But if the effective diameters of the inner and outer pulleys are different, the V-belt will get pulled in one direction or the other as it tries to keep the two pulleys connected. Since the outer pulley doesn’t rotate, the force exerted by the V-belt makes the inner pulley rotate instead, and this is the output of the transmission.

The second thing is how the transmission ratio changes. Remember, each pulley is split into “pulley pairs,” with the V-belt running between them. To alter the transmission ratio, one pulley pair moves farther apart, causing the V-belt to drop deeper into the groove between the pulley halves, while the other pulley pair moves closer together, causing the V-belt to ride up higher in the groove between the pulley halves.

This changes the effective diameter of the pulleys—as far as the V-belt is concerned, the first pulley just got smaller, while the second pulley just got bigger, and this changes the transmission ratio. Making one pulley effectively larger than the other will drive the output in one direction, while switching the ratio will drive the output in the other direction, and you can vary the ratio smoothly all the way down to zero, where the pulleys are the same effective diameter and the output doesn’t move at all (it’s in a geared neutral mode).

Since SRI basically just invented Inception Drive, they’re the first to admit that “there is a great deal to be learned about this transmission.” For example, while the gear ratio can’t be changed instantaneously, they’re pretty sure that it can be changed quickly enough for most robotic applications. There’s also lots of work to do to investigate total system efficiency as well as durability, and the next generation of prototypes will help to more fully quantify the characteristics of the drive. But while they figure stuff out, here are some control strategies that the authors suggest roboticists might get excited about:

- Force control: Apply a constant force at the motor (or spring) and determine the output force by modulating the gear ratio;

- Velocity control: Apply the most efficient motor velocity and determine the output by modulating the gear ratio;

- Energy flow control: Monitor the amount of energy distributed across the system at any point in time, and move it using the transmission ratio and the motor controller to optimize efficiency or power;

- Impedance control: Because the transmission ratio is adjustable, the impedance of the system can be tuned for optimal environmental interactions (excellent for managing impacts and human safety factors).

“An Ultra-Compact Infinitely Variable Transmission for Robotics,” by Alexander S. Kernbaum, Murphy Kitchell, and Max Crittenden from SRI, was presented in June at ICRA 2017 in Singapore.

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.