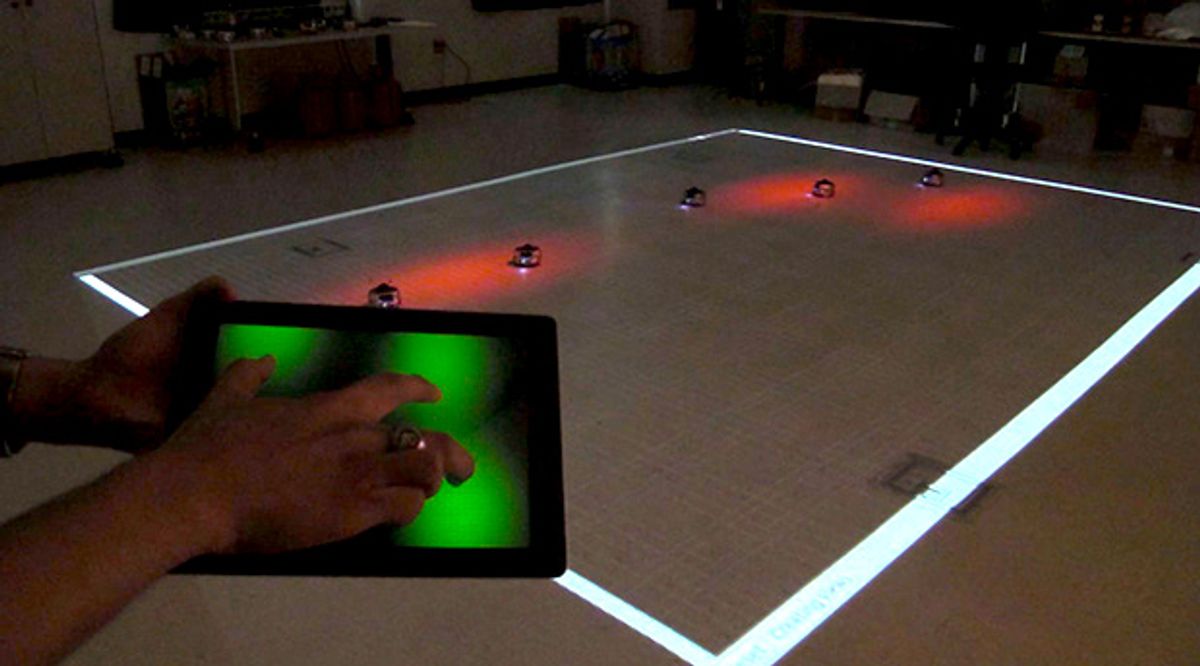

As robots get smaller, cheaper, and more capable, it often makes sense to rely on swarms of little bots instead of one big one, and as swarms grow in size and complexity, intuitive methods of real-time control become critical. Georgia Tech’s GRITS Lab has developed a way to dynamically control large swarms of robots using just a tablet and a finger (or two).

“It’s not possible for a person to control a thousand or a million robots by individually programming each one where to go,” said Magnus Egerstedt, Schlumberger Professor in Georgia Tech’s School of Electrical and Computer Engineering. “Instead, the operator controls an area that needs to be explored. Then the robots work together to determine the best ways to accomplish the job.”

While robots are usually pretty good at determining efficient ways of completing tasks, they’re far less good at adapting to change and figuring out which tasks need to be done, especially if they need to change priorities on the fly. This is where the humans come in: with Georgia Tech’s system, a novice user can assign goals just by poking at a tablet, and a swarm of robots will coordinate with each other to achieve those goals.

The scenario that this system was designed for is the obligatory disaster search-and-rescue mission, where you have a large amount of rugged terrain that needs to be covered optimally. Robots are good at doing things optimally, and they have no trouble cooperating to search an area. Meanwhile, a human can identify areas of interest, and set those areas as goals for the robot swarm. Once a new goal is assigned, the robots redeploy themselves based on an algorithm that guarantees optimal coverage, without the human having to get any more involved. Here’s that part of the system in action:

The latest research works very much like this, except you have a human dynamically selecting the areas that the robots should care about most.

This sort of control can also come in very useful in commercial contexts, according to the researchers:

“In the future, farmers could send machines into their fields to inspect the crops,” said Georgia Tech Ph.D. candidate Yancy Diaz-Mercado. “Workers on manufacturing floors could direct robots to one side of the warehouse to collect items, then quickly direct them to another area if the need changes.”

Cleaning robots, surveillance robots, delivery drones… Really, any multi-robot system that needs to adaptively cover an area could benefit from an interface like this, and it works even if (especially if) you have no experience with robots, and no idea what you’re doing. And that’s what makes it so cool.

[ GRITS Lab ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.