We first covered SRI’s electroadhesion tech in 2010 (although it’s been public since at least 2008). More recently, SRI spun it out into a company called Grabit. Grabit was demonstrating an electrostatic gripper at RoboBusiness earlier this month, so we thought it might be fun to take a look at some of the more exciting stuff that SRI has done with electroadhesion, including conveyors, climbing robots, and delivery drones.

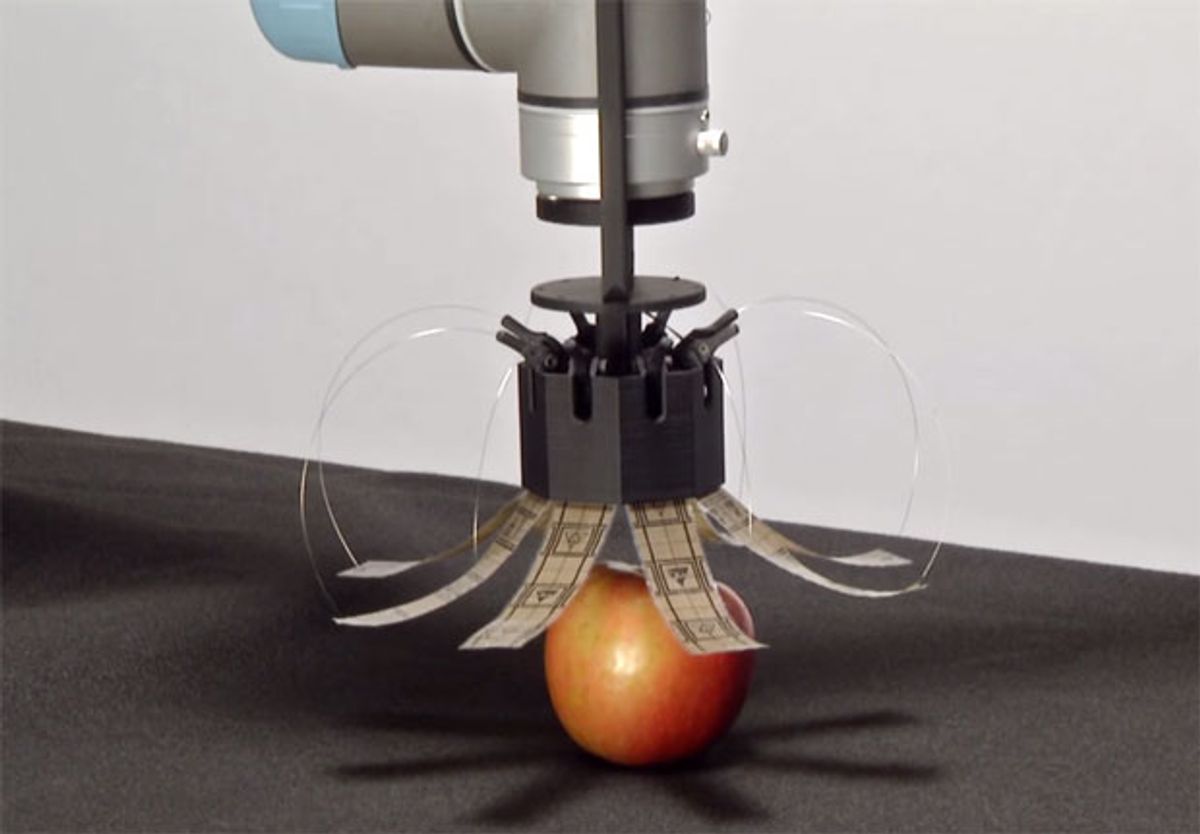

Here’s the gripper that Grabit was demoing in Boston:

Electroadhesion can introduce a “stickyness” in just about anything that you can turn on and off whenever you want. It’s sort of like duct tape that comes with a toggle switch. The flexible bits are electrodes that generate alternating positive and negative charges, inducing opposite (i.e. attractive) charges in whatever they’re close to (anything at all, conductive or not), causing them to stick. Like geckotape, electrostatics depend on a lot of surface contact to adhere well, which is a problem if you’re trying to attach to surfaces that aren’t flat. Grabit’s “fingered” gripper is compliant enough to get around that issue.

As far as a business model goes, grabbing stuff is probably the best way to actually, you know, make money or whatever. If you like that sort of thing. But there are other interesting applications, like climbing walls:

Here’s a slightly wobbly YouTube video:

Electroadhesive surfaces stick to things, but that also means that things stick to electroadhesive surfaces. Flip the gripper idea around, and you get a conveyor belt that can grab onto objects and carry them up at steep angles:

And no demo of any robotic technology would be complete without delivery drone integration:

[ Grabit ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.