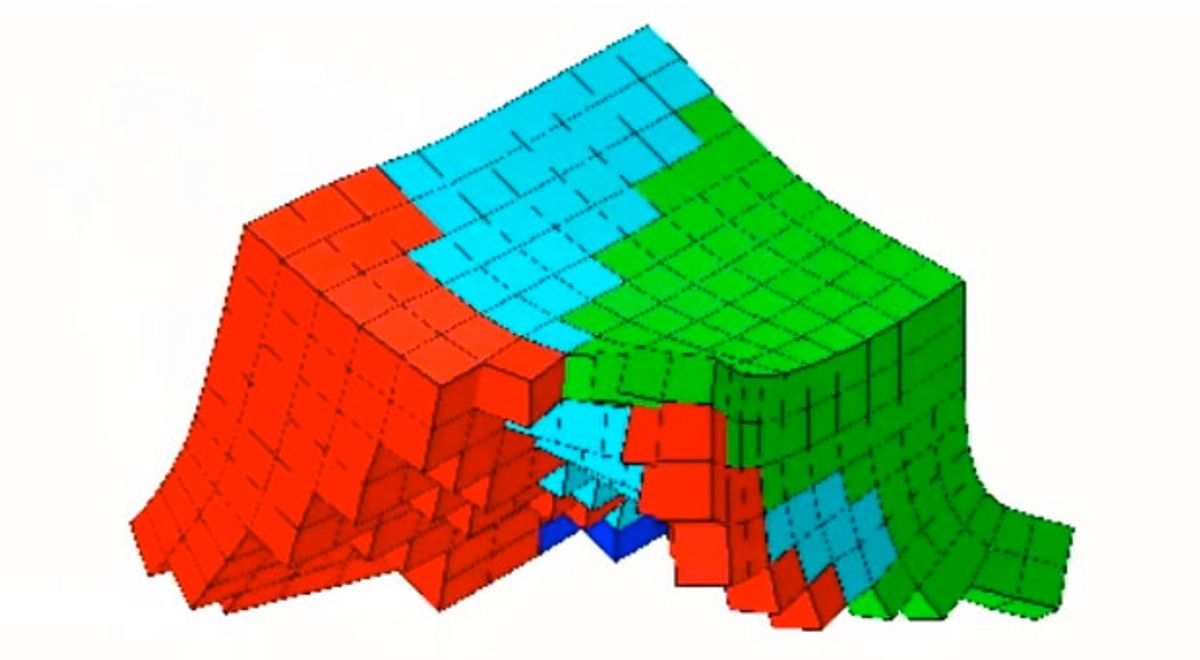

This crazy looking thing is a simulated robot, made up of two different kinds of muscles along with bones and soft tissue for structure. This robot wasn't designed, it was evolved over a thousand virtual generations to move as fast, as far, and as functionally as possible.

It's nice that these researchers (including Jeff Clune from the University of Wyoming, who posted this video) are totally aware that these robots are wacky little things, but it's kind of amazing how successful evolution is at creating success out of just a few basic structures. And in the greater scheme of things, 1,000 generations is not a whole lot: in human terms, that's only 25,000 years, while modern Homo Sapiens have been around for ten times as long.

If this whole thing seems a bit familiar, it's because it's from some of the same researchers who worked on the Golem Project over a decade ago, including Cornell's Hod Lipson. Golem took things a step farther by evolving robots and then actually building them with a 3D printer:

The Golem paper, Automatic design and manufacture of robotic lifeforms (one of the coolest paper titles ever), can be read here.

The current research has been published in Proceedings of the Genetic and Evolutionary Computation Conference, with the impressive title of Unshackling Evolution: Evolving Soft Robots with Multiple Materials and a Powerful Generative Encoding.

[ Jeff Clune ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.