There are a lot of contenders in the race to become the dominant software platform for robots. One of the factors that will determine the winner is, of course, achieving critical mass. By making your software open source, you can reduces barrier to acceptance to a minimum, helping it to spread faster. This is what is happening with ROS, the Robot Operating System created by Silicon Valley robotics firm Willow Garage.

Research labs across the world are adopting ROS at fast rate. And because these labs are packed with some of the freshest and most clever minds in robotics, the ROS community is constantly adding more capabilities to the software. ROS now offers many advanced packages for robot vision, navigation, and mobile manipulation, among others.

As I considered the evolution and adoption of ROS, I thought that it would be great to have not only start-ups and research labs but also industrial robot companies embracing ROS. (That would be good for ROS too, of course, because the industrial segment is still a big chunk of the robotics market.) But could that ever happen?

In industrial robotics, I feel that lots of people are constantly reinventing the wheel, with different robot manufacturers developing their own proprietary operating system and controller. The result: You can't program a robot from one manufacturer and reuse that same program on a robot from another manufacturer. Furthermore, if you want to develop an add-on component or peripheral for a robot, you need to establish a relationship with the robot's maker; in other words, you need "permission" to get access to the "black box" that is their robot controller.

Maybe things work this way because industrial robotics have traditionally been a slow-moving, conservative, and expensive business. And it's also been tied to manufacturing, where everybody is trying to keep their edge on new ways to make better products at better prices using advanced technologies. As I pointed out in an article about the stagnation of industrial robotics, the proprietary operating system is an important piece of the business model that industrial robot makers rely on. For this reason, I thought that having a major industrial robot manufacturer adopt ROS would never happen.

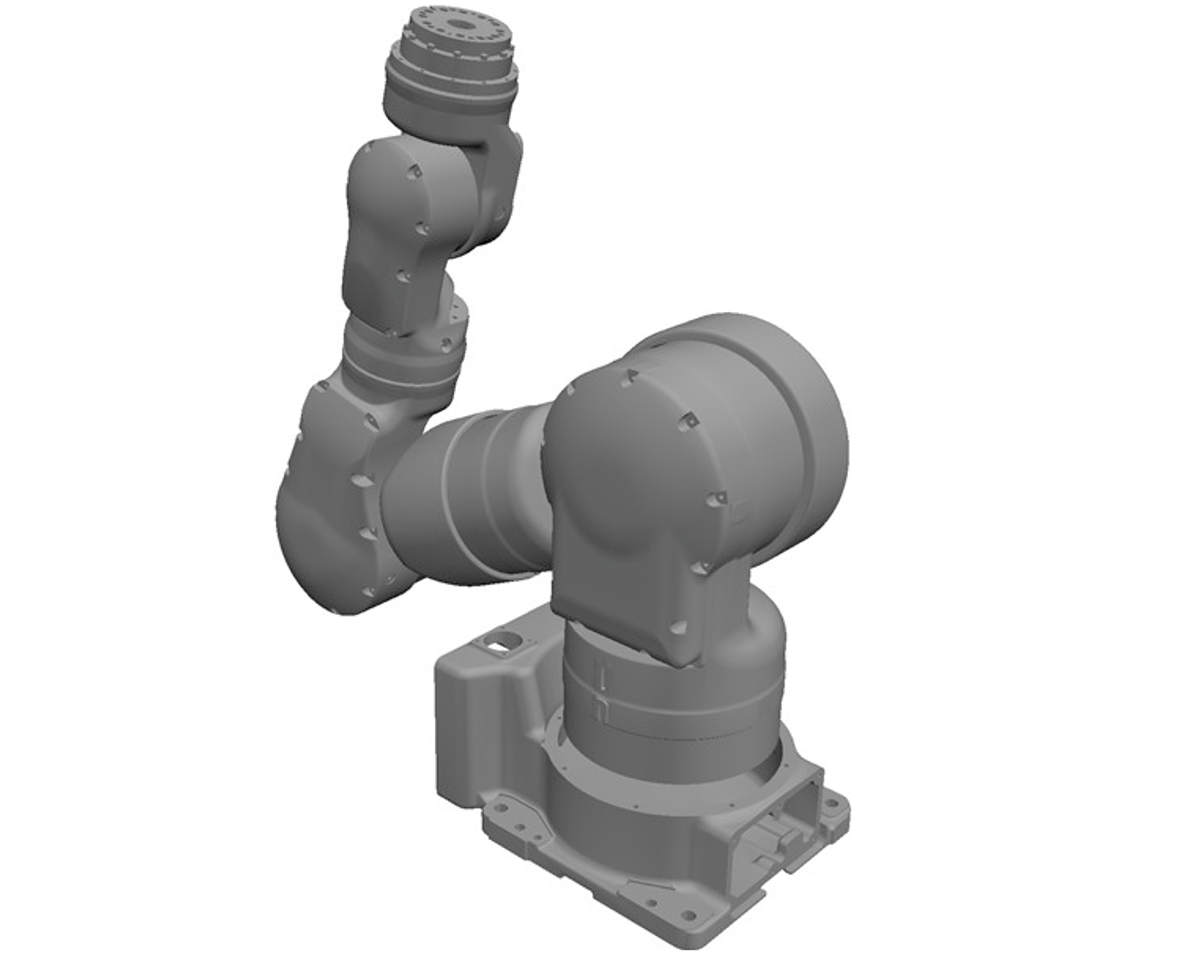

Well, I was wrong. It was a nice surprise to hear that the Southwest Research Institute (SwRI), a private R&D organization based in San Antonio, Texas, announced recently that they've reached an agreement with Motoman, one of the largest industrial robot makers in the world, to develop a ROS interface for the Motoman SIA20 7-axis robot [CAD image and photo above]. By making its robots compatible with ROS, it seems that Motoman is betting that all those tools developed by the ROS community will become very enticing for its customers. And if customers demand that those capabilities be available, relying on a proprietary system doesn't make help you.

This could be the beginning of something big. If more industrial robotics companies adopt ROS, this could enable a lot of technology transfer from the research world to real-world applications. And then, after we get every robot on ROS, imagine we could connect them through the Net so they could share a common knowledge base.

Now you’re ready for a real robot revolution.

Samuel Bouchard is a co-founder of Robotiq, in Quebec City.