Engineers and Architects Are Already Designing Lunar Habitats

NASA and the European Space Agency’s plans for moon colonies call for advanced life-support systems and shielding from cosmic rays

Skidmore, Owings & Merrill is the architectural firm known for designing and engineering Dubai’s Burj Khalifa, the world’s tallest building, such iconic structures being one of the firm’s specialties. But at its New York City office, architects are working on something even more striking—drawings for SOM’s first extraterrestrial assignment. The firm is designing a moon base in collaboration with the European Space Agency (ESA) and MIT.

Daniel Inocente, the lead designer, presents schematics and renderings of white puffy pods scattered across the lunar landscape, connected by tubular walkways and surrounded by robots and solar panels and astronauts, all overseen by a recognizable blue orb in the sky.

These visions may never come to be, but they’re helping ESA think through possible futures. The moon offers many opportunities. Planetary scientists want to study its composition to learn about the early solar system and Earth’s origins. Astronomers want to build radio telescopes on the far side. Medical researchers want to understand how the human body reacts to extended stays in low gravity. Explorers want to test equipment or produce propellant for voyages to asteroids, Mars, and beyond.

Talk of sending people back to the moon—for the first time since the Apollo missions ended in the 1970s—has heated up recently. In 2016, the head of ESA announced Moon Village, a deliberately nebulous vision encouraging private and public players to collaborate on robotic and human exploration of the moon. Last year, eight Chinese volunteers completed a yearlong stay in a simulated habitat called Lunar Palace 1 to test life-support systems.

And while private industry doesn’t plan to send people to the moon’s surface anytime soon, rockets from SpaceX and Blue Origin could drastically reduce the cost for governments to do so. Just a few months ago, U.S. vice president Mike Pence pledged to return astronauts to the moon within five years.

But settling people on the moon will require experts to work out some kinks, to put it lightly. These include coping with the harsh environment, building structures out of locally sourced materials, mastering life support, and dealing with one potentially deadly complication for which we currently have no clear solution: dust.

The three most important factors in identifying a site for a lunar settlement are, as any realtor will tell you, location, location, location. Skidmore, Owings & Merrill (SOM) has deemed the most enticing option to be a nice bit of property on the rim of the Shackleton Crater near the moon’s south pole.

There’s strong evidence that permanently shadowed regions of the crater contain water ice from ancient comets—good for drinking, cooking food, bathing, making concrete, and splitting into oxygen and hydrogen for rocket propellant.

Wherever they build, space architects and engineers face constraints that traditional practitioners never worry about. The moon has almost no air, of course, so any habitat must be sealed and pressure-tight. And while most space rocks burn up in Earth’s atmosphere, the moon’s surface is constantly pelted with micrometeoroids. So structures would have to be built to take that punishment.

Gravity is about one-sixth as strong there as on Earth. That can allow for long-span structures, but it also requires more anchor points. And weak gravity makes it hard to dig: Pushing down pushes you up. Where temperatures are extreme, habitats will need to incorporate powerful heating and cooling systems, and the materials they are made of will have to withstand dramatic amounts of expansion and contraction.

Then there’s the radiation. The sun emits a constant stream of high-speed protons and electrons—the solar wind. While Earth’s magnetic field shields us from most of this wind, the moon has no magnetic field, so it all hits the surface. Even more dangerous are the sun’s coronal mass ejections. These events hurl bursts of higher-energy protons and electrons into space. A strong one could generate several sieverts—a sievert being a measure of radiation exposure—on the moon’s surface, enough to kill a person if she or he doesn’t return to Earth for a bone marrow transplant. And if such dangers weren’t enough to endure, astronauts on the moon will also be subject to a constant shower of galactic cosmic rays, which will probably increase their lifetime risk of cancer.

At SOM’s New York City office, Inocente describes his firm’s proposal to 3D-print walls around the pods of a lunar habitat to guard against deadly radiation. Long-term occupants will need up to 3 meters of shielding to protect themselves from galactic cosmic rays. It wouldn’t make sense to ship tons of concrete from Earth, so astronauts will apply what’s known as in situ resource utilization—in other words, they’ll use what’s there.

In SOM’s conception, the walls will be made from lunar soil—which, lacking organic material, is more properly called regolith. One way to do this is to 3D-print the walls, either all in one piece where they’ll stand, or as bricks that lock together when stacked. Some space architects propose depositing regolith-based cement, layer by layer, through a robotically controlled nozzle.

But what if the liquid used in the cement mixture evaporates or freezes before the concrete in the wall or brick sets? European researchers working with the architecture firm Foster + Partners have explored binding liquids and injection methods that would prevent this, and they have printed a section of a wall using a regolith simulant. However, contractors would still need to ship the liquid binder or special cement powder to the moon.

SOM prefers extruding melted regolith through a nozzle like hot glue. Yet another approach is sintering—heating regolith to near its melting point until it fuses. In one ESA project, called RegoLight, researchers focused sunlight into an intense beam and traced it over the surface of regolith simulant, baking bricks layer by layer. The process was slow, though, and the test bricks were weak, so many researchers believe the winning strategy will be microwave sintering, which uses microwave ovens or beams to bind dust. SOM is closely following the sintering research.

For relatively low habitats, regolith may simply be piled on top of metal structures (with space left open for maintenance). Another, more speculative option, is to place habitat modules inside the moon’s lava tubes—large empty tunnels through which molten rock once flowed.

Regolith will be used not only to protect buildings but also to pave launchpads and roads. Brent Sherwood, chair of the Space Architecture Technical Committee of the American Institute of Aeronautics and Astronautics (AIAA), suggests baking regolith paving tiles in microwave ovens. Spacecraft landing on platforms or vehicles driving on roads made of these tiles would kick up less dust. The roads would also make it easier for robots to navigate the terrain. “You basically want to make the surface of the moon into a predictable factory floor, like an Amazon warehouse,” he says.

Hanna Läkk, a space architect at ESA with a background in architecture and textile technology, has offered a more far-out use of regolith. With collaborators, she’s managed to melt simulant and extrude it into fibers that can be robotically wound across metal frameworks into fibrous shell structures. With this fabrication method, a habitat module could be placed in a crater with woven webs spanning it, supporting more regolith piled on top. They have also used a robot to fabricate a miniature version of such a cover. In the end, many techniques for using regolith will likely be adopted in any future moon colony.

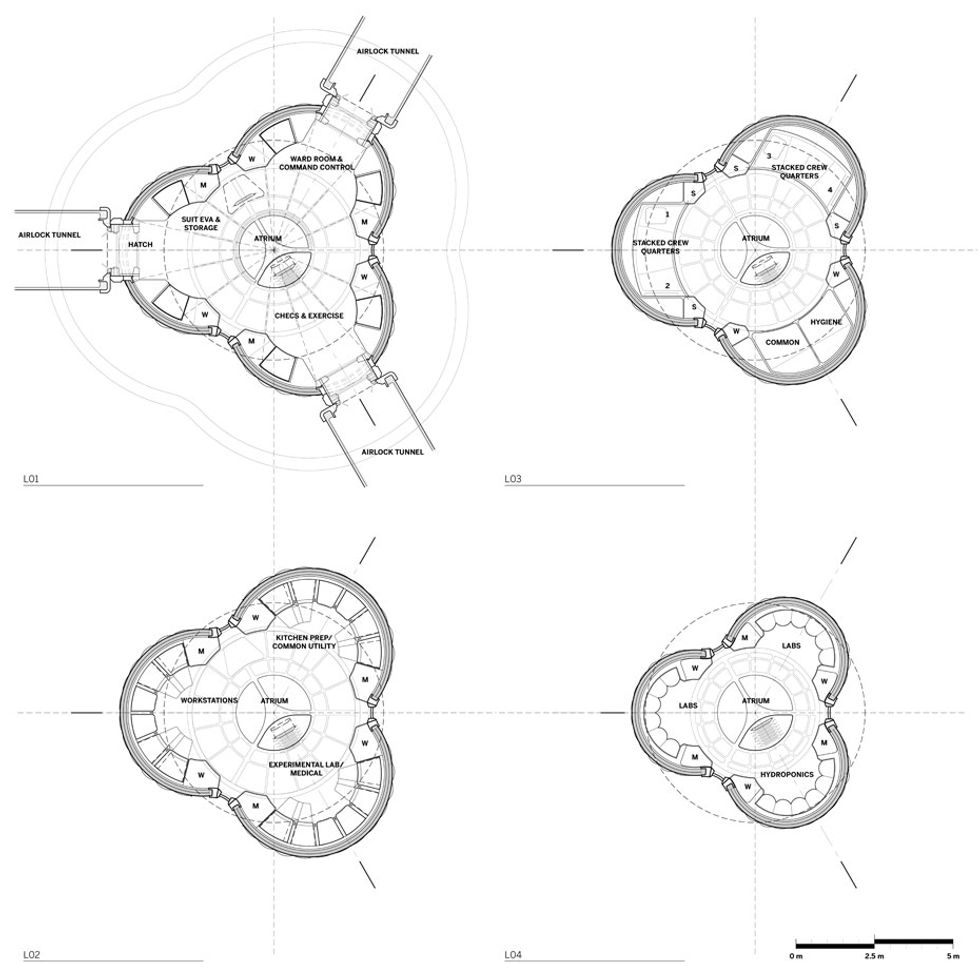

Behind barriers made of moon regolith, what will lunar habitat modules actually look like? SOM’s in-progress designs are an outgrowth of proposals made by engineers over the decades, usually for domes or cylinders, sometimes buried or half-buried.

Space architects and engineers widely believe that the first moon habitats will resemble units of the International Space Station (ISS). “The first-generation technology is a little bit less sexy” than sci-fi renderings, says Haym Benaroya, a mechanical and aerospace engineer at Rutgers University and the author of Building Habitats on the Moon: Engineering Approaches to Lunar Settlements (Springer, 2018). The original habitat will be some sort of pressure vessel covered in regolith for radiation protection—in a sense, a buried tin can.

According to Sherwood, who worked on ISS modules for Boeing, engineers already know how to fabricate, test, launch, and repair such a unit. “The amount of learning that we’ve gotten out of the space station is enormous,” he says.

Eventually, we might switch to inflatable modules—which could expand to greater volumes, once we better understand how to integrate them with rigid structures and how to pack them so they unfold properly. Bigelow Aerospace, a company based in Las Vegas, licensed NASA patents to build an inflatable unit that was attached to the ISS in 2016 for testing. While it’s currently being used only for storage, Bigelow continues to collect data on its response to temperature changes, radiation, and impacts from space debris.

In its work with ESA, SOM has opted for something between a can and a balloon. The module its architects have designed is vaguely cylindrical and stands 9.5 meters tall. It has three floors, with a vertical core that allows inhabitants to climb between them. Three inflatable portions run the height of the module and add living space to all floors. The bottom level has three doors to connect to neighboring units.

SOM hasn’t yet decided on the technology for environmental control systems, life support, power, and crew accommodations. But the common architectural practice of getting users involved early should make it a comfortable place to live. Larry Toups, a space architect at NASA overseeing contracts for space habitation concepts, says engineers sometimes need reminders about the user experience: Waste treatment shouldn’t go next to the galley, for example.

One thing SOM never had to think about when designing Burj Khalifa was recycling urine. The first life-support system on the moon might be “open loop,” like those on the Apollo missions: Oxygen, food, and water are provided, and waste is disposed of on-site. By one calculation, each person would need 5 to 15 metric tons of expendables—mostly air, food, and water—per year.

A more likely first step, though, would be a physicochemical recycling system like that on the ISS. The space station collects urine, wastewater, and condensation from astronauts’ sweat and breath, then filters it and makes it drinkable. A set of molecular sieves (using crystals of silicon dioxide and aluminum dioxide) scrubs CO2 from the air, while electrolysis splits water to create oxygen.

NASA’s Next Generation Life Support project is working on some new approaches, but “we are often not trying to invent new chemistry,” says Molly Anderson, principal technologist. Mostly NASA wants to increase the efficiency of current systems. The agency also wants to make the hardware lighter, more reliable, and easier to fix. As for new toys, the team is testing prototypes for a compressor to recharge space-suit oxygen tanks, pyrolysis systems that use heat to break down solid waste into useful elements, and portable DNA sequencers for monitoring microbes on surfaces and in the water.

Anderson says the moon makes life support easier than on the ISS in at least one way: Gravity lets you shower and flush toilets.

The next stage for life support on the moon would be a bioregenerative system, in which organisms within the habitat provide food, scrub the air and water, and break down waste. ESA’s Micro-Ecological Life Support System Alternative (MELiSSA) program ran an experiment in which three rats and some algae lived together for six months at a time. The rats turned oxygen into CO2 and the algae did the reverse.

We might even build with biology. ESA’s Läkk has grown bricks with mycelium and plant matter and shown that the fungus withstands both simulated weightlessness and the radiation it would encounter on the moon. This locally grown material could potentially replace regolith as a construction material.

Likely, we’ll need a hybrid system with some food shipped from Earth. Even if scientists genetically modify crops to produce all the required nutrients, astronauts may still need variety for gut health. People also won’t want to eat the same thing every day, and turning plants or algae into food takes a lot of processing. “We don’t want to send astronauts there for the purpose of being farmers,” Anderson says.

Sherwood of AIAA agrees on the need for variety—especially if the moon is ever to attract space tourists. “You can’t have a hotel until you can mix a martini and cook an omelet,” he says. But we know little about how to cook in low gravity.

To allow people to live on the moon, SOM must also plan for a robotic workforce. “The surveying, the regolith moving, the construction, the resource extraction, the simple maintenance—none of those things are best done by people,” Sherwood says. SOM expects that robots will set up a habitation module, and maybe a food production module, and construct walls of regolith before anyone moves in.

But there’s one complication that can be deadly for both humans and machines: dust. For billions of years, micrometeoroid strikes have pulverized the lunar surface to produce sharp, glassy shards of dust in a place with no air or water to smooth out the edges. Between 10 and 20 percent of the mass of the moon’s shallow regolith consists of particles smaller than 20 micrometers across, like fine talcum powder.

These particles are electrostatically charged [PDF] from the solar wind, so they hover, too tiny to see, and stick to everything. On the Apollo missions, after just a few hours of moonwalking, the dust caked boot treads, wore away space suits, scratched lenses, destroyed machinery, clogged air filters, and irritated the astronauts’ eyes and noses. If inhaled, it may even cause cancer.

SOM has proposed dust-off areas at habitat entrances, but even if they render interiors spick-and-span, they won’t prevent degradation of outside equipment. “We know what’s in regolith and we know why it’s the way it is,” Sherwood says, “but no one has a clue how to design a sustainable system around those environmental conditions.”

Getting to the moon was hard, and staying there will be tougher still. But if engineers and architects can overcome the odds, a world of possibilities awaits.

This article appears in the July 2019 print issue as “Homesteading the Moon.”