Fiber Lasers Mean Ray Guns Are Coming

A clever configuration of industrial lasers is set to finally make laser weapons practical

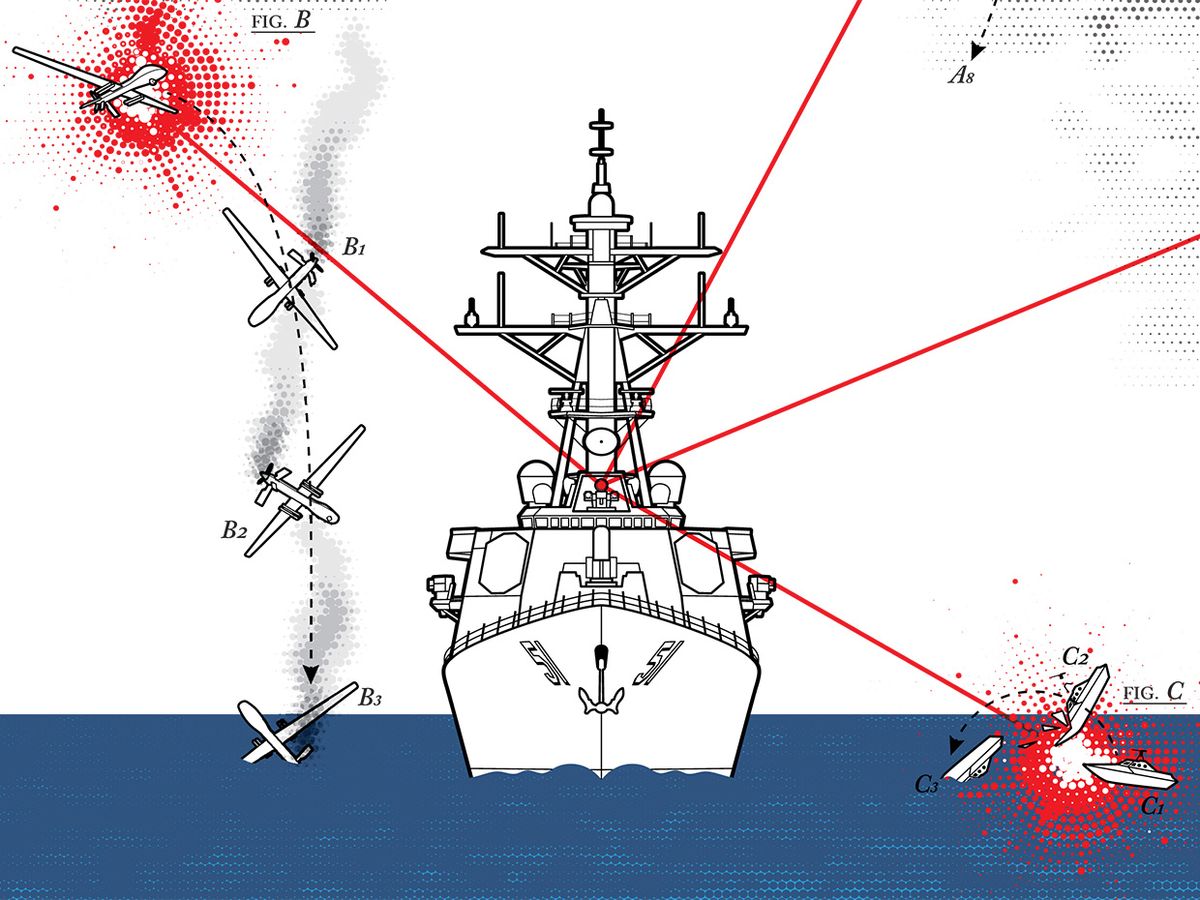

The U.S. Navy’s most advanced laser weapon looks like a pricey amateur telescope. As it emerges from a chassis high on the USS Ponce to look out onto the daytime sky above the Persian Gulf, its operator sits in a darkened room elsewhere on the ship holding what looks like a game controller. The screen before him is showing a small boat floating near the Ponce, carrying a dark object. The infrared beam hitting the object is invisible, but you can see one spot grow brighter until the object suddenly explodes, sending metal shards spiraling into the water.

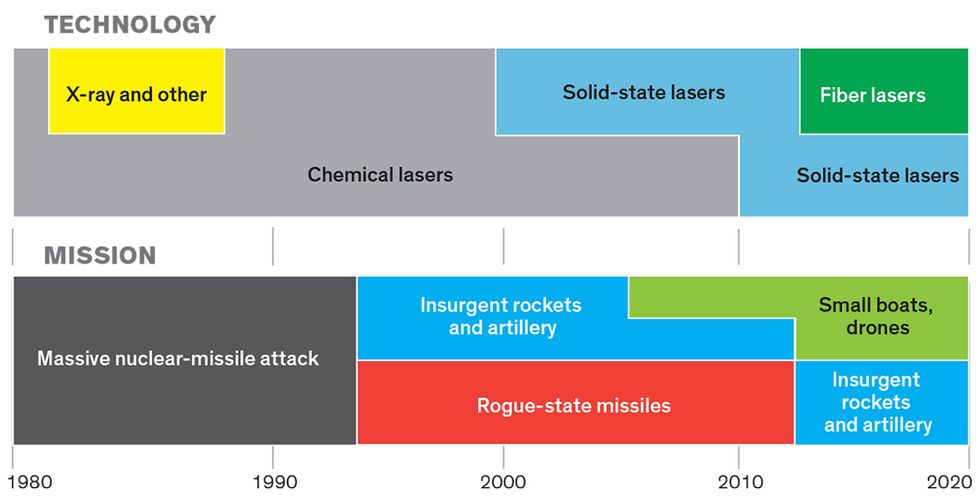

This weapon, cobbled together from a half-dozen industrial cutting and welding lasers to produce a total power of only 30 kilowatts, was hardly the megawatt monster military scientists dreamed of decades ago to shoot down ICBMs. But it’s a major milestone, advocates say, toward a future in which directed-energy weapons are deployed in real military engagements. Such a future, they add, will come from changes in mission and in technology. The mission shift has been going on for years, from global defense against nuclear-armed “rogue states” to local defense against insurgents. The technology shift has been more abrupt, toward the hot new solid-state technology of optical-fiber lasers. These are the basis of a fast-growing US $2 billion industry that has reengineered the raw materials of global telecommunications to cut and weld metals, and it is now being scaled to even higher power with devastating effect.

Pentagon officials think the technology for high-energy lasers, like the one tested on the now-decommissioned Ponce, can serve a variety of roles on land and at sea: zapping the cheap rockets, artillery, drones, and small boats loaded with weapons that insurgents have deployed in places like Iraq and Afghanistan. Today, destroying an insurgent rocket costing around a thousand dollars can require a tech-laden Patriot interceptor costing $2 million to $3 million. By comparison, a laser shot from a fiber-laser weapon would cost only $1 in diesel fuel, officials claim.

On Land, at Sea, in the Air

On Land Deployment: 2022 Power: 100 kilowatts The Indirect Fire Protection Capability Increment 2 will be tested from the High-Energy Laser Mobile Test Truck.

At Sea Deployment: 2020 Power: 60–150 kilowatts The US $150 million High Energy Laser and Integrated Optical Dazzler with Surveillance (HELIOS) program will be installed on a destroyer and tested at sea.

In The Air Deployment: 2021 Power: Tens of kilowatts The Pod-Mounted Self-Protect High-Energy Laser Demonstrator will be tested on a fighter jet in flight. Deployment: 2023 Power: Multi-kilowatt class The Low-Power Laser Demonstrator will target a missile in flight from a drone.

Other military powers besides the United States are also aiming for fiber lasers at the 100-kW level needed to reliably destroy targets kilometers away. China’s Poly Technologies, Israel’s Rafael, and the German defense firm Rheinmetall have developed fiber lasers at least as powerful as the prototype the U.S. Navy demonstrated on the Ponce. The United Kingdom is spending £30 million to build a 50-kW laser called Dragonfire, and Japan is investigating fiber lasers to block attacks by short-range rockets as well as North Korean ballistic missiles. But the United States has led the way since launching a program 15 years ago to develop electrically pumped high-energy lasers, and it has benefited from the rapid growth of high-power industrial fiber lasers, led by IPG Photonics. Based in Oxford, Mass., the company was founded in Russia in 1990 but moved its headquarters to the United States in 1998. It now has facilities around the world and dominates the global market for fiber lasers.

“The Defense Department has wanted a laser weapon system ever since the laser was invented,” says Robert Afzal, senior fellow for laser and sensor systems at the defense contractor Lockheed Martin, in Bothell, Wash. “The key element has been to build this high-power electric laser small enough and powerful enough that we can put it on Army trucks, Air Force planes, and Navy ships, and not take everything [else] off” to make room for it. Though there are still other technologies in development, it appears that fiber lasers will be the technology that will accomplish that mission first.

The Pentagon has been dazzled by visions of laser weapons since physicist Gordon Gould walked into the then months-old Advanced Research Projects Agency in 1959 with a proposal to build a laser. Gould, one of three people credited with conceiving the laser, had gotten the idea of generating coherent light as a 37-year-old grad student at Columbia University in late 1957. Within weeks of his inspiration, he had sketched out his vision of a pair of mirrors at opposite ends of a long, thin cylinder. Chain smoking over a pile of references and a notebook at his kitchen table, he realized the laser could concentrate light into a powerful beam. Once he worked out the laser idea, Gould abandoned his Ph.D. studies and set out to patent his invention, eventually enlisting the help of TRG, the company where he started working in early 1958.

Nuclear-missile defense was among the top items on the agenda the U.S. Department of Defense handed its new research arm. So the fledgling agency was deeply intrigued by the prospect of a speed-of-light weapon. ARPA bestowed $1 million (about $8 million today) on Gould’s proposal. (Unfortunately for him, though, once the Pentagon decided to classify the work, his youthful dalliance with the Communist Party blocked him from getting the security clearance he needed to work on his own project.)

Making a powerful beam required more than a pair of mirrors. It needed something to put between the mirrors that emitted light and a way to pump energy into that material. The first functioning laser was built around a solid, synthetic ruby, which contained light-emitting chromium atoms that could be energized by bright pulses of photons from a flash lamp. Other types soon followed: An electric discharge passing through a tube filled with helium and neon, it was found, could generate coherent light. So could pulses of current in gallium arsenide diodes with their edges polished as mirrors.

But the Pentagon wanted high power, and that was impossible to get from any of these sources. In ARPA’s initially classified Project Seaside, researchers built solid-state lasers with rods several centimeters thick, but most of the input light energy went into heating the light-emitting solid, while too little came out in the beam. So that approach was abandoned. Similar problems eliminated early gas and semiconductor lasers from consideration.

The U.S. military was about to give up on laser weapons in the mid-1960s when researchers at the Avco-Everett Research Laboratory, near Boston, came up with a startling new approach. They burned a hydrocarbon fuel and forced the hot exhaust gas through a set of rocketlike nozzles so it flowed between a pair of mirrors, generating tens of kilowatts of infrared laser light. [See “Gasdynamic Lasers,” IEEE Spectrum, November 1970.]

That flowing-gas technology would fuel U.S. laser weapon research throughout the Cold War. New fuels capable of delivering megawatt levels of power led to dreams of orbiting laser battle stations. U.S. president Ronald Reagan’s Strategic Defense Initiative spent billions researching space-based lasers to shoot down Soviet ICBMs. After the Cold War ended, the U.S. Air Force spent billions more to squeeze a huge missile-defense laser into a Boeing 747, to combat launches by rogue states like North Korea. In 2010, this megawatt-level behemoth actually shot down a ballistic missile in a test—a first—but it was far from practical. Then Secretary of Defense Robert Gates killed the program, declaring, “There’s nobody in uniform that I know who believes that this is a workable concept.”

Smaller, less-powerful chemical lasers developed for the Pentagon’s new anti-insurgent mission ultimately met a similar fate. In 1996, the United States and Israel joined in a program to test a 100-kW-class chemically fueled gas laser built by TRW (now part of Northrop Grumman). The Tactical High Energy Laser shot down rockets and artillery shells in 2000 and 2001. Around the same time, the 2000 suicide attack on the USS Cole underlined the danger of small boats and the need to find a countermeasure for them.

But this TRW laser had two big problems: First, it was impractically large, consisting of four 18-wheeler-size trailers and a separate beam director about as large as a supersize searchlight. Second, and more important to Pentagon logistics experts, were its special chemical fuels. Special fuels are always logistics liabilities because any supply glitch can leave weapons useless. Worse, the chemicals in question were basically weapons all by themselves. They react to form hydrogen fluoride, a gas that can destroy corneas, scorch lungs, and severely damage skin—posing serious risks to the soldiers operating it.

Meanwhile, another laser technology was advancing rapidly. In the 1960s, Zhores Alferov in Russia and IEEE Medal of Honor recipient Herbert Kroemer in the United States invented structures that dramatically improved the performance of semiconductor devices, including diode lasers, by confining light and current flow—an accomplishment that earned them the 2000 Nobel Prize in Physics. Over a period of about seven years, ending around 1977, Bell Labs had stretched diode-laser lifetimes from mere seconds to 100 years for use in fiber-optic communications. After that, others increased power dramatically and improved efficiency to the point where diode lasers could convert about half of the input electricity into laser light.

Diode lasers don’t generate the tightly focused beams needed for weapons, but they opened up another possibility: replacing lamps as the source of input energy in solid-state lasers. Fired into slabs of glass or crystal doped with light-emitting elements, these lasers have a huge advantage over lamps because they generate light far more efficiently and emit a single wavelength. Fiddle with the composition of the semiconductor that makes up the laser and its wavelength can be matched to one soaked up almost completely by the crystal, allowing it to convert that input light into laser energy very efficiently. Diode-laser pumping allowed the first solid-state laser weapon test bed to convert about 20 percent of the input electric energy into the output laser beam—a huge improvement on 1 percent for lamp-pumped lasers.

Here, high efficiency means much more than saving the Pentagon a few bucks on the power bill. The input energy not converted into light winds up as waste heat, which limits performance and must be removed from the laser. In practical terms, diode lasers put kilowatts and even tens of kilowatts within reach, though not the megawatts needed for long-range missile defense.

The High Energy Laser Joint Technology Office (HEL-JTO) was launched to develop solid-state laser weapons. These systems, using slabs of glass or crystal, reached their peak in March 2009 with a Northrop Grumman demonstrator. It delivered a steady 105-kW beam for a full 5 minutes. [See “Ray Guns Get Real,” IEEE Spectrum, July 2009.] The laser didn’t require special fuels or produce toxic gases, but it weighed 7 metric tons and occupied 10.8 cubic meters—about the volume of a large cement truck.

The U.S. military, of course, wanted something smaller than a cement truck. And another of the HEL-JTO programs, the Robust Electric Laser Initiative, managed to do it. With a mandate to develop solid-state lasers that were better suited for the battlefield, HEL-JTO set itself a goal of building a 100-kW laser that occupied about 1.2 cubic meters and could generate more than 150 watts per kilogram, operating at 30 percent efficiency or better. Two of the four projects HEL-JTO launched considered new variations on a hot technology for laser machine tools: fiber lasers.

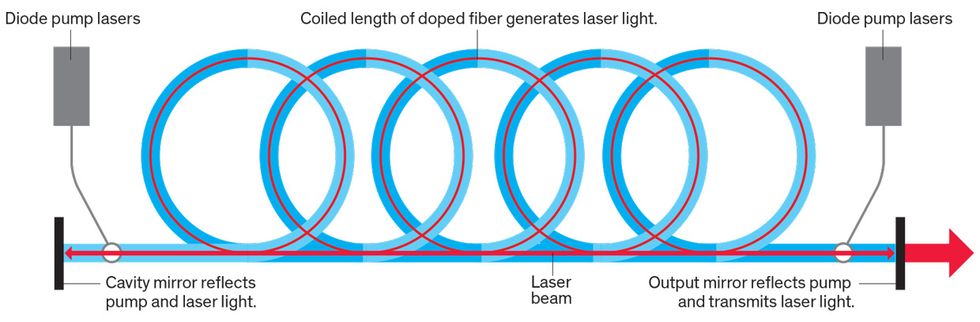

A fiber laser is essentially an optical fiber with some important modifications. It has a central core with a slightly higher refractive index than the surrounding glass cladding. A telecom fiber uses that structure to guide optical signals from laser transmitters through its central core, which is made of extremely pure and nearly lossless silica. In a fiber laser, however, this central core contains light-emitting atoms, usually ytterbium.

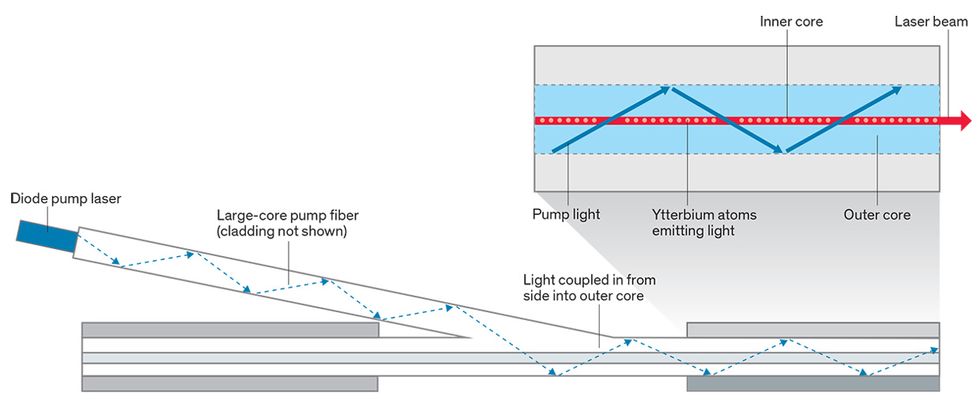

Fiber lasers also have an extra layer, between the light-emitting central core and the outer cladding. This intermediate layer, called the outer core or inner cladding, has a refractive index in between that of the core and the outer cladding. The inner cladding is also made of high-purity glass because its job is to guide light from external diode pump lasers directed into the outer cladding through separate optical fibers. From there, the light bounces along inside the outer core as it travels the length of the fiber, repeatedly passing through the inner core, where the ytterbium atoms grab the photons and emit laser light. The outer core is deliberately shaped unevenly—a D shape, an ellipse, even a rectangle—to ensure that as much light as possible is directed through the central core.

Like the signal in a telecommunication fiber, the light emitted by ytterbium atoms in a fiber laser remains confined within the light-guiding central core. But instead of traveling tens of kilometers in one direction to the next optical amplifier or receiver, the light in a fiber laser bounces back and forth between a pair of reflectors fabricated into each end of the fiber. With each pass, more ytterbium atoms amplify the light, building up the laser power.

The tight connection between the inner and outer cores ensures that most of the pump light is absorbed by ytterbium atoms. And in 2016, IPG Photonics reported converting just over half of the electric power to light in the lab, well above what you could get from the bulk crystal or glass of older, solid-state laser schemes. Generating light in the long, thin fiber core also produces a beam that can be focused tightly over long distances, which is exactly what’s needed for delivering lethal energy to targets a few kilometers away. Because fiber lasers are thin—with diameters in the range of 125 to 400 micrometers—they have a high surface-to-volume ratio, allowing them to dissipate heat much faster than shorter and thicker lasers.

Fiber lasers started small, largely as spin-offs of the development of fiber amplifiers for long-haul telecommunications in the 1990s. The push to high power came from IPG. Starting with a 1-W fiber laser in 1995, the company has basically added an order of magnitude to that figure every three years through 2012. The company grew along with the power of its lasers. Its 2017 sales of $1.4 billion accounted for about a third of the revenue of the entire market for industrial lasers that year.

Industrial fiber lasers can be made very powerful. IPG recently sold a 100-fiber laser to the NADEX Laser R&D Center in Japan that can weld metal parts up to 30 centimeters thick. But that high of a power output comes at the sacrifice of the ability to focus the beam over a distance. Cutting and welding tools need to operate only centimeters from their targets, after all. The highest power from single fiber lasers with beams good enough to focus onto objects hundreds of meters or more away is much less—10 kW. Still, that’s adequate for stationary targets like unexploded ordnance left on a battlefield, because you can keep the laser trained on the explosive long enough to detonate it.

Of course, 10 kW won’t stop a speeding boat before it can deliver a bomb. The Navy laser demonstration on the USS Ponce was actually half a dozen IPG industrial fiber lasers, each rated at 5.5 kW, shot through the same telescope to form a 30-kW beam. But simply feeding the light from even more industrial fiber lasers into a bigger telescope would not produce a 100-kW beam that would retain the tight focus needed to destroy or disable fast-moving, far-off targets. The Pentagon needed a single 100-kW-class system for that. The laser would track the target’s motion, dwelling on a vulnerable spot, such as its engine or explosive payload, until the beam destroyed it.

Alas, that’s not going to happen with the existing approach. “If I could build a 100-kW laser with a single fiber, it would be great, but I can’t,” says Lockheed’s Afzal. “The scaling of a single-fiber laser to high power falls apart.” Delivering that much firepower requires new technology, he adds. The leading candidate is a way to combine the beams from many separate fiber lasers in a more controlled way than by simply firing them all through the same telescope. Two approaches looked promising.

One idea was to precisely match the phase of the light waves emerging from several identical fiber lasers so they add together to form a single, much more powerful beam. The light waves of each fiber laser are coherent, meaning all emitted waves march along in lockstep, with every crest locked in synchrony with every other crest, and every trough with every other trough, and so on. In principle, coherently combining the beams of several different fiber lasers should make a powerful beam that could be tightly focused onto targets kilometers away. Phased-array antennas can combine, in synchrony, the coherent outputs of many radio transmitters, but the trick is much more difficult with light. That’s because light wavelengths are orders of magnitude shorter—around 1 micrometer compared with centimeters for radar—making it extremely hard to align the waves precisely enough for them to add together constructively rather than interfere with one another.

The other approach is to ignore phase and combine beams from many fiber lasers that each have optics that limit them to emitting in a unique spectral slot. The resulting beams each occupy a different wavelength. So when they are combined into a single beam, that beam spans a range of wavelengths, which don’t interfere with one another. Called “spectral beam combining,” the technique is adapted from wavelength-division multiplexing technology, which has been enormously successful in packing more data into fiber-optic communications channels. [See “Is Keck’s Law Coming to an End?,” IEEE Spectrum, February 2016.]

To implement the technology, Lockheed developed special optics that bend light from separate fiber lasers at angles that differ slightly depending on their wavelength, the same way prisms separate the colors of the spectrum. That bending merges their outputs to form a single beam. In 2014, the company “built and tested on our own money a 30-kW laser to figure out the physics and basic engineering,” says Afzal. That system combined 96 beams of 300 W each at different wavelengths into a single beam with a total power of 30 kW. The lasers produce higher-quality beams when run at such relatively low powers, and it is easier to combine their output to produce a high-power beam than to build a single high-power laser with the same beam quality, says Afzal.

Lockheed scaled that technology to 60 kW in a laser it delivered to the U.S. Army Space and Missile Defense Systems Command, in Huntsville, Ala., last year for installation in a battlefield-ready military truck. That laser “set a world record for [weapons-grade] solid-state laser efficiency, in excess of 40 percent,” claims Adam Aberle, lead of the command’s high-energy laser technology development and demonstration. Such high efficiency greatly eases the problem of thermal management. With that efficiency, a laser system whose beam is at 100 kW generates less than 150 kW of waste heat. Compare that with more than 400 kW of waste heat, which is what Northrop Grumman’s 2009 nonfiber laser put out while delivering a beam of the same power. On 1 March, Lockheed announced that by 2020, it would supply the U.S. Navy with two copies of a similar laser, called HELIOS, that will deliver at least as much power. The Navy will install one on a destroyer and integrate it with the ship’s battle management system, and it will test the second on land at the White Sands Missile Range, in New Mexico.

“We view development of the high-power, beam-combined fiber laser as the final piece of the puzzle,” says Afzal. Maybe so, but the quest for laser weapons is far from over. Now that a high-energy laser technology looks viable, armed services around the world will need to figure out how to deploy it in combat, and against what. Those challenges, in turn, will require designing, building, testing, and refining the hardware needed to turn a powerful laser into a mobile weapon system, including trucks, ships, and aircraft to carry the laser; sensors and computer systems to spot and track targets; power management systems to deliver the electricity to the laser; cooling systems to keep it from overheating; and optics to focus the powerful beam onto moving targets long enough to destroy or disable them.

Nor is hardware the full extent of the challenge. Military R&D groups will be turning their powerful new lasers over to operational groups like the U.S. Naval Sea Systems Command to integrate the new technology into combat plans and develop procedures to support it in operation. The operational groups also are charged with critical tests of laser lethality against potential targets and with the strategy and tactics for using lasers in the field.

In short, the ability to blast some rockets out of the sky over a test range won’t be enough to earn laser weapons a place in the arsenal. It has taken the military almost 60 years to get to the point where lasers look like they might actually be useful in combat. But the Pentagon is full of military brass who grew up with “kinetic weapons”—guns and rockets—and must be thoroughly convinced that the age of Buck Rogers has really arrived. Without such widespread support, there won’t be money for the hard and expensive work of deploying a radically new weapon. As one wag put it famously (and in a completely different context), “No bucks, no Buck Rogers.”

This article appears in the April 2018 print issue as “The Ray Guns Are Coming.”

On Land

Deployment: 2022

Power: 100 kilowatts

The Indirect Fire Protection Capability Increment 2 will be tested from the High-Energy Laser Mobile Test Truck.

On Land

Deployment: 2022

Power: 100 kilowatts

The Indirect Fire Protection Capability Increment 2 will be tested from the High-Energy Laser Mobile Test Truck. At Sea

Deployment: 2020

Power: 60–150 kilowatts

The US $150 million High Energy Laser and Integrated Optical Dazzler with

At Sea

Deployment: 2020

Power: 60–150 kilowatts

The US $150 million High Energy Laser and Integrated Optical Dazzler with  In The Air

Deployment: 2021

Power: Tens of kilowatts

The Pod-Mounted Self-Protect High-Energy Laser Demonstrator will be tested on a fighter jet in flight.

Deployment: 2023

Power: Multi-kilowatt class

The

In The Air

Deployment: 2021

Power: Tens of kilowatts

The Pod-Mounted Self-Protect High-Energy Laser Demonstrator will be tested on a fighter jet in flight.

Deployment: 2023

Power: Multi-kilowatt class

The