A Tesla in Every Garage? Not So Fast

Elon Musk’s sunny vision of the electric-car future sells well to the tech elite, but it won’t captivate the masses

Last summer, as I drove around the San Francisco Peninsula, I caught glimpses of a sea change in American automobile culture. Plug-in electric vehicles and charging stations seemed to be everywhere. Near the entrance to Stanford University, I witnessed a three-car fender bender involving only electric cars. And perhaps most remarkable: the prevalence of the Tesla Motors Model S, a luxury electric sedan that’s become the new status symbol among the tech-savvy. With more than 90,000 built to date, the Model S is now a common sight on Bay Area highways and byways.

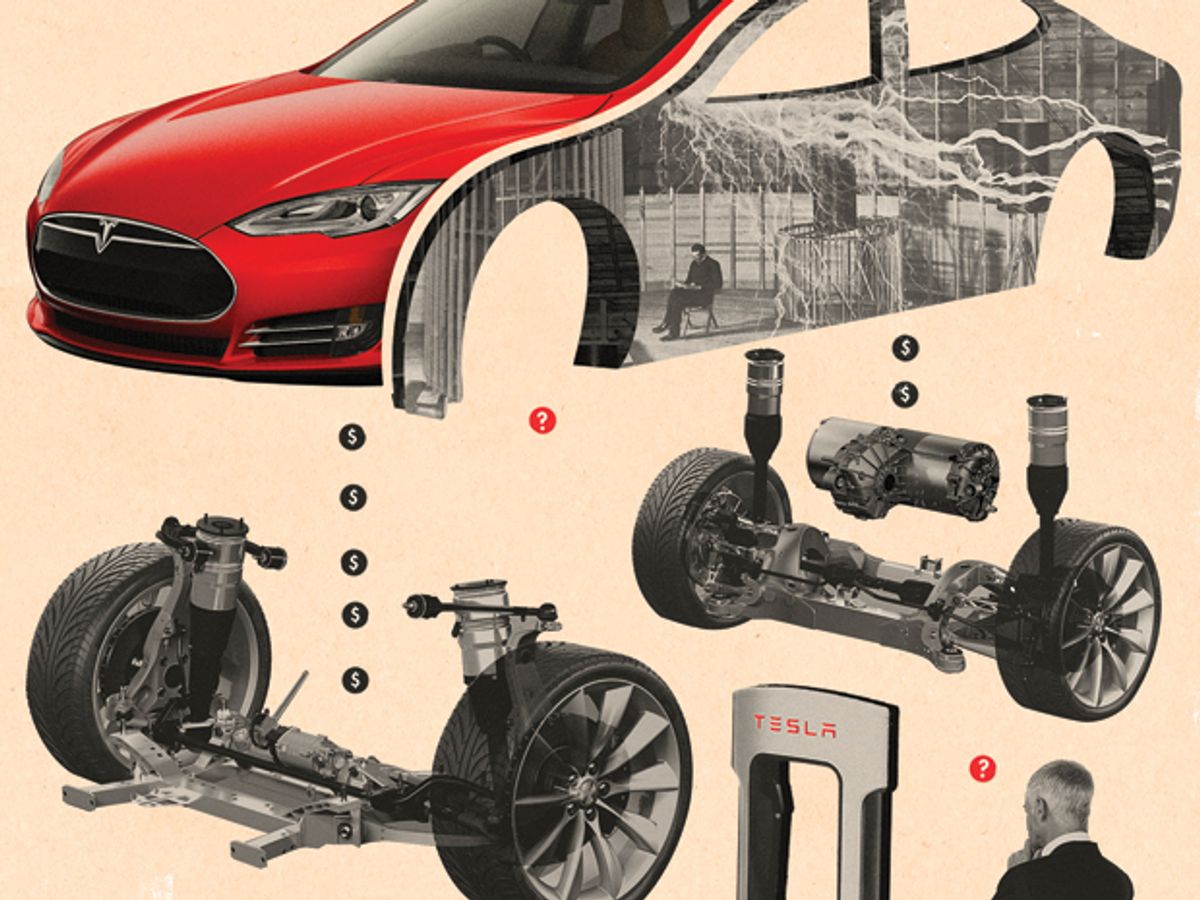

The Model S and Tesla’s newer Model X sport-utility vehicle are unquestionably engineering marvels. And in the vision of Tesla CEO Elon Musk, they are nothing less than agents of change. Rivaling the best-performing internal-combustion automobiles, these green supercars are designed to reconcile comfort, power, and convenience with environmental sustainability, an ethos encapsulated in the current marketing slogan for the Model S: “Zero Emissions. Zero Compromises.”

Sales of the high-end models S and X—versions of which sell for well over US $100,000—are supposed to provide the revenue needed to produce the Model 3, an affordable electric supercar for the masses, slated to be unveiled in March and in production in 2017. Eventually, as they and other electric vehicles proliferate and get tied into rooftop photovoltaic and energy storage systems, they will disrupt Rust Belt car manufacturing as well as the fossil-fuel industry, accruing environmental benefits in the process. As Musk sees it, Tesla Motors is not simply an automaker. It is an “energy innovation company,” a critical element in its broader quest for “zero emission power generation.”

Skeptics in financial and environmental circles have questioned the ability of the Bay Area startup to deliver this future, as well as the whole idea that the car market can be substantially “greened.” I won’t rehash their arguments here. I’m a historian of science and technology, and I do believe that Tesla is making history, of a sort. I spent last summer talking with electric vehicle owners about cars, class, and politics. And what I learned suggests that the battery electric vehicle, or BEV, represents a more thorough upsetting of the existing order of things than Musk and his acolytes might like to admit.

Electric cars have been aroundas long as gasoline-powered ones. But their strong resurgence in recent decades is due almost entirely to California’s air-quality politics, which led to the creation of the Zero Emission Vehicle (ZEV) mandate in 1990.

Promulgated by the California Air Resources Board (CARB), the state’s “clean air” agency, the mandate was the first such initiative in the world, and it had international repercussions. It compelled the seven major automakers then doing business in California (Chrysler, Ford, General Motors, Honda, Mazda, Nissan, and Toyota) to start producing vehicles that emitted no harmful tail-pipe pollutants, with a rolling quota for each manufacturer based on its market share of conventional vehicles. The larger the share, the larger the ZEV quota. Specifically, CARB mandated that a carmaker’s California fleet consist of “at least 2 percent ZEVs [in] each of the model years from 1998 through 2000, 5 percent ZEVs in 2001 and 2002, and 10 percent ZEVs in 2003 and subsequent model years.”

The board was forbidden from specifying the kinds of technology that carmakers could use to achieve the desired air-quality outcomes, but the only technology that then met the ZEV criteria was the battery electric car. The car industry, uninterested in shaking up existing product lines, responded with something like this: Consumers want an automobile that does it all—one that is clean but also as fast, long-ranged, stylish, and convenient as a good gasoline vehicle. Given the state of the art of electric vehicles, this is impossible. We will roll out advanced zero-emission technology eventually, but it will take time.

This was a straw argument. Automakers had never before let the quest for perfection get in the way of marketing a merely good or just plain awful gasoline automobile. Nevertheless, the argument worked: In 1996 CARB weakened the mandate, eliminating the quotas for the years 1998 to 2002 (which it later extended by a year). In return, the industry agreed to deploy some BEVs ahead of schedule, but in very small numbers and only for lease.

Even as the industry dragged its collective heels on the battery EV, it continued to push for alternatives to satisfy the ZEV category—in particular, hybrid electric and fuel-cell electric vehicles, which the board agreed to recognize in 1998. The inclusion of hybrids enabled portions of an automaker’s ZEV quota to run on gasoline. Eventually, CARB created the oxymoronic ZEV subcategory of “partial” zero-emission vehicles (PZEVs), which implied hybrid technology.

Hydrogen fuel-cell cars, by contrast, would emit no tail-pipe pollutants. Ever since its invention in the mid-19th century, the fuel cell had impressed technologists as a kind of miracle engine that combined the best features of the battery and the internal combustion motor. By electro-oxidizing gaseous and liquid fuels stored in conventional tanks, fuel cells would enable electric vehicles to use the vast and existing fossil-fuel infrastructure and drive farther than battery-powered EVs.

At least that was the theory. In fact, researchers were—and still are—struggling to make the technology practicable. Yet the promise of a fuel-cell super EV was enough for CARB to further revise the mandate. In a series of increasingly complex equivalence formulas, the board allowed automakers to gain ZEV credits through a mixture of battery, fuel-cell, and hybrid electric vehicles. It also allowed carmakers to trade ZEV credits and bank them.

The ZEV mandate set the stage for General Motors’ EV-1. The company had unveiled an all-electric concept car called the Impact at the January 1990 Los Angeles Auto Show. But the Impact had been commissioned by then CEO Roger Smith for internal political reasons rather than out of any serious desire for large-scale production, according to Michael Shnayerson in his classic 1996 book, The Car That Could: The Inside Story of GM’s Revolutionary Electric Vehicle. Smith quickly realized he’d let a genie out of a bottle and went into damage control, publicly pointing out the limitations of existing rechargeable batteries. But with ZEV quotas to fulfill, GM introduced the Impact to the market in 1996 as the EV-1, for lease in California and Arizona.

Now, CARB didn’t require GM or any other carmaker to maintain its leased fleets of such first-generation “compliance cars.” And so the automakers didn’t, instead choosing to repossess and decommission them. GM sent most of its 1,117 EV-1s to the crusher, an event that outraged popular sentiment, as documented in the film Who Killed the Electric Car?

It was as a direct response to this fiasco that Silicon Valley engineers Martin Eberhard and Marc Tarpenning founded Tesla Motors in 2003. In crafting their business model, they embraced the auto industry’s rationale for not producing the BEV: that existing batteries were inadequate and that consumers would not buy electric cars that did not deliver pulse-elevating performance. Accordingly, they decided to produce a high-end sports car—the Roadster—equipped with a lithium-ion battery, the most powerful available chemistry and also the most promising.

In this way, the green supercar myth, invented by the automaking establishment to maintain the status quo, became the basis of a business plan to undermine that establishment.

Joining Tesla Motors in 2004, Musk kept the supercar philosophy alive. As a business model, it made sense. For an upstart company trying to overthrow the status quo in an industry with enormous barriers to entry, the hype associated with supercars was and is essential to Tesla’s ability to attract investment capital.

In important ways, however, the supercar mythos has obscured the technological and industrial implications of battery-powered electric vehicles. Observers tend to focus on battery cost per kilowatt-hour as the most important factor in commercializing the electric vehicle. Indeed, Tesla is devoting a vast effort to drive costs from upwards of $400 per kilowatt-hour to below $200. With plenty of help from the state of Nevada and in partnership with Panasonic, it is now building an enormous $5 billion battery-pack assembly plant (the so-called Gigafactory 1) near Reno.

Large battery packs do represent a significant share of the cost of an electric vehicle. In the highest-performance versions of the Model S, these packs account for up to 30 percent of the suggested retail price of $95,000 to $138,000.

But this obsession with cost per unit energy obscures the real challenge with EV batteries: battery aging. While increasing the capacity and power of batteries has been relatively straightforward, making batteries last longer has proved a hard and incremental slog. Battery lifetime in cellphones, tablets, and other portables is less of an issue because portable consumer electronics are designed to last only a few years. Where electric vehicles are concerned, however, lifetime is crucial.

Evaluating the useful life span of a battery is an imperfect science. The basic metric is the number of charge-discharge cycles, which can mean very different things depending on how and where the battery is used. Designers of most contemporary EVs favor lithium-ion chemistry, and in particular the variants that are optimized for power and energy. Such batteries tend to have a relatively short shelf life, age rapidly when exposed to high temperature and voltage, and get worked harder than the batteries in cellphones or laptops. Some types of lithium-ion batteries are also highly flammable and require expensive control systems to be used safely.

EV batteries are, of course, rigorously tested in the lab. But real-world driving presents a much more complex set of conditions, and assumptions about battery lifetimes are often disproved in the field. Some Nissan Leaf owners, for instance, were dismayed to learn that driving their cars a lot caused the battery capacity to decline far more rapidly than they expected.

What is certain is that even the best batteries will wear out long before the electric motors they serve. Which means that battery-powered EVs have hefty replacement costs that consumers may or may not even realize, let alone be willing to pay. Consider as well that carmakers typically do not produce their own advanced battery cells (although a few, like Tesla and BMW, do assemble such cells into battery packs). Auto executives no doubt loathe the idea of creating an electric fleet whose chief component is made not by them but by dedicated manufacturers like LG Chem or Panasonic. In the world of vertically disintegrated manufacturing, parts suppliers get paid first.

Why don’t automakers simply build their own EV batteries? For one thing, established battery makers have economies of scale, often in multiple lines of business; trying to catch up would require Herculean effort. Only Nissan has taken this route, and then only in collaboration with the Japanese electronics giant NEC. Even there, as demand for the Nissan Leaf has waned, the automaker has been looking to cut its costs by switching to South Korea’s LG Chem, which makes the battery pack for the Chevrolet Volt plug-in hybrid electric.

Indeed, most new EV users are choosing to lease rather than buy, in part because automakers are promising cheaper and more capable batteries in future versions. But that tactic may backfire: Subsidizing the cost of battery aging in this way may keep consumers happy, but it will doubtless erode the carmakers’ ability to profit from EVs.

It’s no surprise, then, that most mainstream automakers have been reluctant to develop battery-powered all-electric vehicles. An alternative, less risky approach to EV technology is the hybrid, which combines a small internal combustion engine with a small battery pack.

The only major automaker thus far to bet big on hybrids is Toyota. It selected a relatively small nickel metal hydride battery, a reliable, safe, and reasonably powerful chemistry pioneered by the U.S. inventor Stanford R. Ovshinsky. In the first-generation hybrids, the battery was used in a power-assist role; unlike the battery in an all-electric car, it was rarely if ever deeply discharged, a practice that shortens battery life span. A hybrid battery typically doesn’t last as long as the automobile itself, but replacement costs average less than $3,500 including labor. As a result, the original Prius, which Toyota introduced in 1997, had a life cycle resembling that of a conventional gasoline automobile.

You can’t say the same for the battery-powered all-electric car. Power packs for the Model S, which currently come in 70-, 85-, and 90-kilowatt-hour versions, are technological wonders, bolstered by an eight-year unlimited-mileage warranty. The battery may indeed still work after eight years, but it will do so at a significantly reduced capacity. Most drivers won’t be too happy to have their driving range erode by 25 percent or more. And the sustainability of such warranties is also an open question, given Tesla’s dependence on generous but temporary public subsidies. These include the $7,500 U.S. federal tax credit to buyers (available for all makes of electric vehicles, up to 200,000 cumulative unit sales), a host of state subsidies, and the ability to earn cash by selling ZEV credits to its competitors.

All this uncertainty over battery lifetimes has had an interesting effect on the used EV market. Lower-end models depreciate faster than gasoline vehicles and are now available at bargain prices. A 2012 Nissan Leaf that sold for around $36,000 retail was worth a little over $8,000 on average in 2015.

The Model S, on the other hand, is retaining most of its value, thanks to Tesla’s resale guarantee, which encourages customers to trade in after three years. The success of this approach has had the unintended consequence of generating a large number of very expensive used EVs. When I visited the Tesla plant in Fremont, Calif., last June, I was struck by the huge lot devoted to surplus supercars. It made me wonder: Why would a reasonably well-informed consumer pay $65,000 to $100,000 for a used Model S with a limited warranty when she could plunk down a few thousand more for a brand-new one with a full warranty?

While battery-lifetime economicstends to be glossed over in public discussions of electric cars, the question of charging infrastructure is robustly engaged. Here, too, however, confusion and paradoxes abound, in good measure because of the supercar ideology. Just like the assumption about EVs themselves, the assumption here is that users must have an experience that replicates the convenience of gas stations as much as possible. So charging means fast charging—the ability to replenish a battery to 80 percent of capacity in 30 minutes or less. This is the approach embraced by Tesla, which has built a proprietary network of supercharging stations capable of adding 270 kilometers of range to a vehicle in a half hour, for free.

Because the large-battery Model S and Model X are so long-legged, this network is located primarily along intra- and interstate corridors in the United States (plus a few in Canada). And because it can be used only by Tesla cars, EV boosters and builders complain that it has stymied the popularization of electric cars. Indeed, Tesla’s supercharging is one of three largely incompatible fast-charging standards in the United States (the others are CHAdeMO and SAE). Some critics have called out the federal government for its failure to support fast charging while simultaneously subsidizing the production of electric vehicles.

Yet the fact is that all EV charging systems require changes in consumer behavior. EV drivers have to learn to plug in their cars at home overnight or at other points of access during the day; they may also have to hire an electrician to reconfigure the receptacles in their garages. Even a high-amperage Supercharger requires the user to wait 30 minutes or more for a “refueling.”

California currently has more nonresidential charging stations than any U.S. state—more than 5,700 as of August 2014. But many of these stations are clustered at a few high-profile workplaces and are virtually nonexistent in apartment complexes and commercial parking lots. This was a frequent complaint among the EV owners I interviewed. Pacific Gas & Electric Co., the major electric utility in northern California, plans to install an additional 7,500 level 2 (that is, 240-volt AC) chargers, at a cost of $222 million to taxpayers.

But the reality is that in some places, charging infrastructure for the masses is hiding in plain sight. Back before direct-ignition and fuel-injection devices improved the starting capabilities of gasoline engines, drivers in colder climates often had to warm the engine blocks of their cars. As a result, 120-volt AC sockets were widely installed in public parking lots in places like Alaska, Canada, and Scandinavia. Much of this Frostbelt infrastructure still exists, and similar plug-in spots could be built quickly and cheaply elsewhere as a cost-effective way of stimulating affordable short-range battery electric fleets. And yet such a system is not being considered seriously in California or anywhere else in the Sunbelt, which speaks to the pervasive influence of big-battery, supercar thinking in current EV planning.

Given the highly competitive nature of the auto industry, why did Tesla receive so much support from other automakers? For example, Daimler and Toyota invested $50 million apiece in Tesla in 2009 and 2010, respectively. And in 2010, the company was able to buy its Fremont plant, which had been built for the Nummi partnership between GM and Toyota, for the rock-bottom price of $42 million.

The answer is that in various ways the major car companies saw the Bay Area startup as a means of hedging their risk during a period of forced technological change. For them, producing small numbers of unprofitable compliance cars was, and continues to be, a short-term annoyance and also raises the disconcerting possibility that these all-electric vehicles will eventually become popular.

But with Tesla, they had an easy way out: The establishment players purchased ZEV credits from Tesla, thereby decreasing the number of compliance cars they had to produce. Such sales raised $51 million for Tesla in the first quarter of 2015.

Daimler and Toyota also contracted with Tesla to supply power trains and battery packs for their compliance cars, notably the Mercedes-Benz B-class hatchback and the RAV4 sport-utility vehicle. Besides outsourcing their ZEV responsibilities, the auto giants were likely motivated by the opportunity to learn what the startup was doing, in the same way that the Nummi partnership allowed GM to learn about Toyota’s lean manufacturing. With all of this industry and government assistance, Tesla’s stock skyrocketed, from around $26 per share in 2010 to more than $250 in mid-2015. In October 2014, amid plummeting oil prices, Daimler and Toyota cashed out, reportedly at a tidy profit. Analysts offered varying opinions as to why, but I think it’s likely that by then their experience with Tesla had proved beyond a doubt that in a world of cheap gasoline, BEVs made no economic sense once the federal rebate money ran out.

And for Toyota, the hybrid is the electric automobile of the future. In a speech in 2013, Takeshi Uchiyamada, team leader of the original Prius project and the current chair of Toyota, dismissed the idea that hybrids are just an interim solution on the way to an all-electric vehicle, adding that his company saw the technology as a “long bridge and a very sturdy one.”

Nobody should write off Musk and Tesla just yet. The fundamental conditions that gave rise to the company persist. Blessed with a mild and dry but fragile ecology as well as rich engineering and capital resources, California has an ecofriendly entrepreneurial culture. It was the ideal setting for Eberhard, Tarpenning, and Musk to cultivate their electric supercar ideology. Nowhere else does the belief in better living through advanced technology run as deep.

Tesla cars, and modern BEVs in general, have largely been shaped within this unique context and are now being exported to the world. But when the technology has been transferred to other contexts, things have not always proceeded smoothly: Recall New York Times reporter John M. Broder’s abortive test drive of a Model S, in which he tried to go from Delaware to Connecticut. He became stranded after he exhausted the battery in cold weather.

The ensuing row between him and Musk (who accused Broder of sabotage) overshadowed the fact that Broder acted precisely as Tesla implied its users should. That is, he took at face value the suggestion that the all-electric vehicle requires no changes in consumer behavior or expectations. Doubtless Broder would have been better off researching how cold as well as hot weather can detract from BEV performance.

Several inconvenient truths thus come into focus. The first is obvious but nevertheless bears repeating: Tesla sloganeering aside, electric vehicles are significantly unlike internal combustion vehicles in fundamental ways. Most important, they age in ways that are not yet fully understood and that have huge implications for ownership and manufacturing.

Less obvious but equally pertinent is that the user’s experience of an electric vehicle will vary significantly depending on climate, culture, and class. Many people identify strongly with their gasoline-fueled vehicles. To them, a silent, clean, superefficient EV is just not a car.

With the Model 3, to be unveiled next month but not expected to be in production until 2017, Musk will be targeting not his loyal and wealthy fans but rather the non–true believers: drivers socialized to the very high levels of cost-effectiveness, convenience, and sophistication of modern gasoline-engine technology. Musk wants the Model 3 to compete with BMW’s 3 Series, but the kind of people who are considering a BMW are unlikely to be awed by electric supercar mythology. And on a practical level, there’s the problem of how to profitably build and market the Model 3 in large volumes, especially outside California. A recent Morgan Stanley analysis forecasts an average cost that’s nearly double the Model 3’s planned $35,000 retail price.

Tesla’s dreams for the Model 3 face a further challenge in Chevy’s Bolt, slated to begin production in late 2016. General Motors has high hopes for this $30,000, 320-km-range BEV, and some have claimed that the auto giant has beaten Tesla in the race to deploy a mass-market all-electric auto. But the Nissan Leaf is a more credible contender for that title, with some 200,000 sold to date. And so the Bolt may end up replicating the unhappy experience of Chevy’s loss-making Volt hybrid-electric car, arriving late to a market created and dominated by an established player. Chevy deployed the Volt more than a decade after Toyota first introduced its Prius, a delay that may prove fatal to the American automaker’s ambitions in this segment. With the Bolt, Chevy is entering a technology field in which the incumbent players have yet to even establish profitability.

Indeed, the reality is that the hybrid is the affordable electric vehicle for the masses. Toyota has sold more than 8 million of them to date, mostly Priuses, an order of magnitude greater than the cumulative sales of all BEVs. Hybrid electrics are a formidable market segment that will prove difficult to challenge, especially as more data on the economics of large EV batteries come to light.

No doubt the technology of BEVs is here to stay in one form or another, and for that alone, Tesla has accomplished something significant. But we can’t ignore the fact that the technology inevitably demands enormous changes in the ways automobiles are manufactured, used, and maintained. The question is not whether the battery electric vehicle can be made to adapt to society but whether society is willing to adapt to it.

This article originally appeared in print as “A Tesla in Every Garage?”

About the Author

Matthew N. Eisler is a visiting assistant professor in the department of integrated science and technology at James Madison University, in Harrisonburg, Va. His first book, Overpotential: Fuel Cells, Futurism, and the Making of a Power Panacea, was published by Rutgers University Press in 2012.

To Probe Further

David A. Kirsch’s The Electric Vehicle and the Burden of History (Rutgers University Press, 2000) and Gijs Mom’s The Electric Vehicle: Technology and Expectations in the Automobile Age (Johns Hopkins University Press, 2004)offerdefinitive accounts of the early history of electric vehicle technology.

Michael Shnayerson’s The Car That Could: The Inside Story of GM’s Revolutionary Electric Vehicle(Random House, 1996) chronicles the making of General Motors’ EV-1.

Sally H. Clarke’s Trust and Power: Consumers, the Modern Corporation, and the Making of the United States Automobile Market (Cambridge University Press, 2007) provides a broad perspective on the U.S. automobile market and culture.

In Auto Mania: Cars, Consumers, and the Environment (Yale University Press, 2007), Tom McCarthy presents an environmental history of the automobile.For an analysis of the contemporary industrial and environmental politics of automobiles, see Daniel Sperling and Deborah Gordon’s Two Billion Cars: Driving Toward Sustainability(Oxford University Press, 2009).