Annoying noise—what the automotive industry calls “buzz, squeak, and rattle” (BSR)—is the leading cause of customer complaints about new cars. Eliminating noise during the design and prototyping phase can pay big dividends…but locating transient, intermittent, ill-defined sounds like BSR or cricket chirps can be exasperatingly difficult.

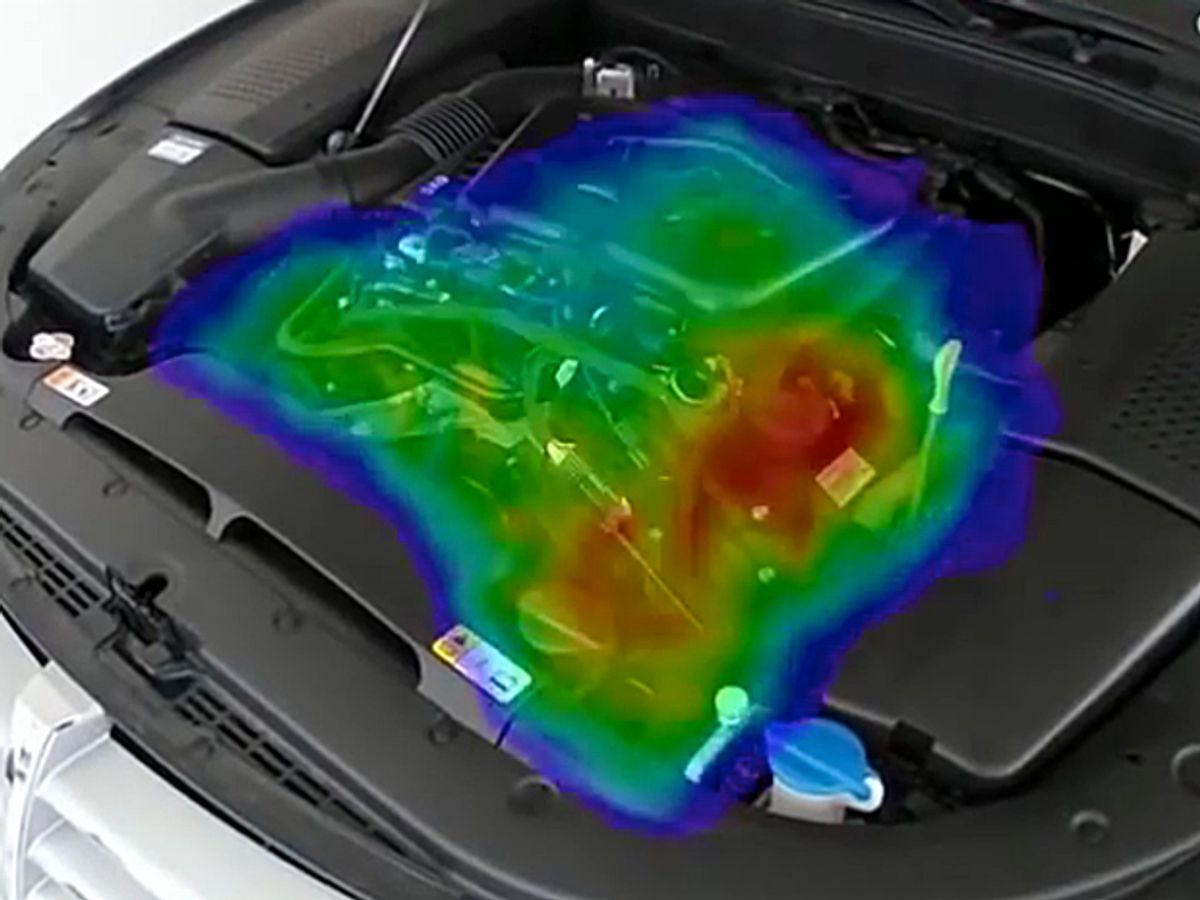

[Localizing dashboard rattle in real time. Video courtesy Hyundai and SM Instruments]

Designers at Hyundai Motor Group enlisted SM Instruments, a Korean acoustic-engineering firm, to help them quickly locate irritating 200 Hz-to-20 kHz noises in car engines, bodies, instrument panels, seats, doors…any place components can vibrate or rub. The result was the SeeSV-S205, a compact, hand-held “sound camera”—an array comprising dozens of inexpensive-but-sensitive MEMS microphones (similar to those found in cell phones) in a five-armed spiral around a video camera. The device (like other acoustic cameras that have preceded it) compares the signals from all of the microphones—the process is called beamforming—to trace the incoming sound back to its source.

Though developed for the automotive industry, the compact acoustic camera can be applied to locating and eliminating unwanted noise in any engineering project. The sleek SeeSV won finalist recognition for Hundai’s Kang-Duck Ih and SM Instruments’ Youngkey K. Kim at the 2014 NI Engineering Impact Awards (formerly the Graphical System Design Achievement Awards), presented 5 August in Austin, Tex.

Images: Hyundai Motor Group and SM Instruments

Douglas McCormick is a freelance science writer and recovering entrepreneur. He has been chief editor of Nature Biotechnology, Pharmaceutical Technology, and Biotechniques.