The use of smart packaging often comes down to cost. If a company is considering including a radio frequency identification (RFID) tag in the packaging of one of its products, the decision may well depend on whether the tag will cut into profits more than it adds value.

One of the obstacles to reducing the costs associated with smart packaging is the need to heat up the nanoparticles so they melt together and achieve good conductivity. Because of this, you can’t print the circuits on substrates made from inexpensive plastics or paper because the heat can destroy these less robust materials.

Now researchers at Duke University say they may have developed a solution for this after an exhaustive look at a range of silver-based nanostructures that are used to print the circuits for smart packing. They discovered that silver nanowires are able to achieve the desired level of conductivity for printed circuits without needing to be heated to the point where they would harm the less expensive substrates.

“The nanowires had a 4,000 times higher conductivity than the more commonly used silver nanoparticles that you would find in printed antennas for RFID tags,” said Benjamin Wiley, assistant professor of chemistry at Duke, in a press release. “So if you use nanowires, then you don’t have to heat the printed circuits up to such high temperature and you can use cheaper plastics or paper.”

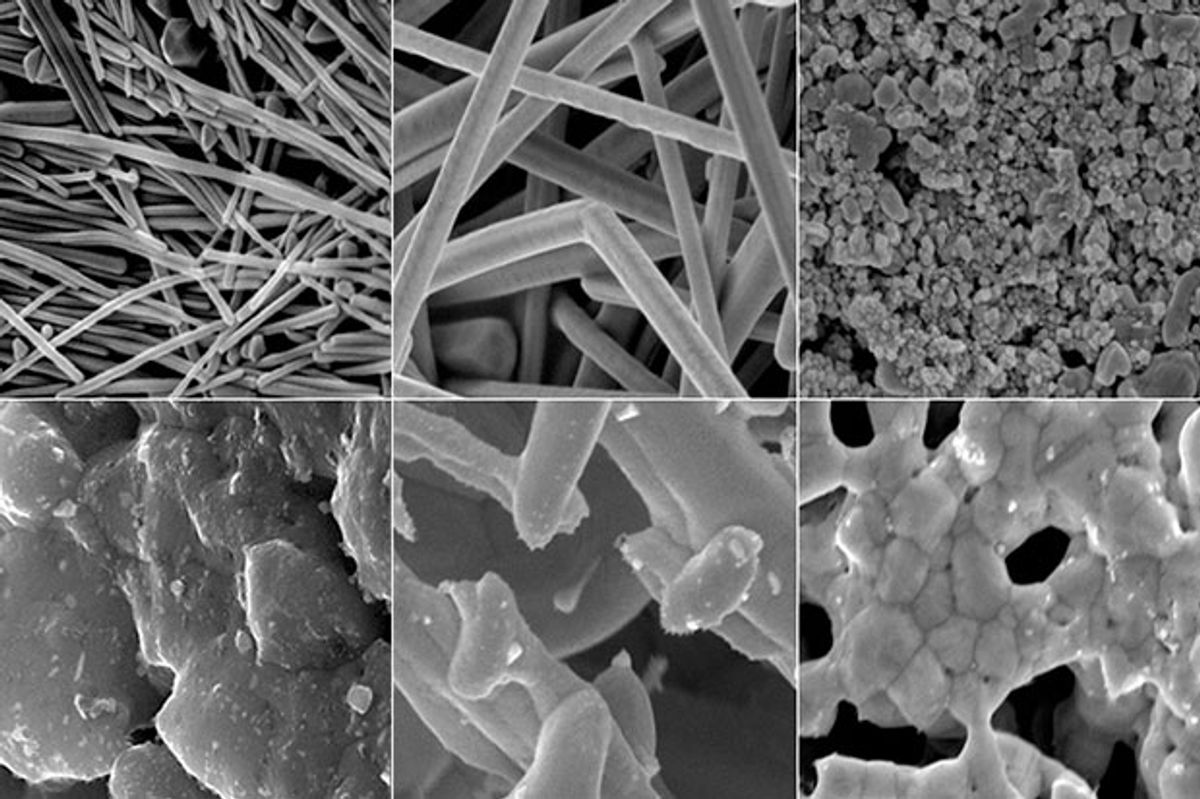

In research described in the journal ACS Applied Materials and Interfaces, the Duke team compared the silver nanowires with silver nanoflakes and silver nanoparticles in the form of films. The results showed that the silver nanowires were able to achieve the tremendous conductivity Wiley describes when heated to only 70 degrees Celsius.

“There is really nothing else I can think of besides these silver nanowires that you can just print and it’s simply conductive, without any post-processing,” Wiley added.

The advantage the silver nanowires have over the nanoparticles and flakes is the individual nanostructures provided by the nanowires offers a better way for electrons to move along without being interrupted. When the electrons have to jump from one nanostructure to another, as they do with the nanoparticle and nanoflakes, they do not flow as easily. For this reason, the researchers were not surprised that the nanowires outperformed the other materials in conductivity, but the extent of the difference was a bit unexpected.

“The resistivity of the long silver nanowire films is several orders of magnitude lower than silver nanoparticles and only 10 times greater than pure silver,” said Ian Stewart, a recent graduate student in Wiley’s lab and first author of the paper.

In continuing research, the team is looking at using aerosol jets to print circuits using the silver nanowire inks. In the future, they will also be looking to see if they can reduce costs further by coating copper nanowires with silver and seeing if they get comparable conductivity.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.