Initially, laboratory-produced graphene was the result of what has been dubbed the “Scotch Tape” method, in which graphene is pulled off in single-layer flakes directly from graphite. The method does produce a high quality, single crystal graphene that possesses many attractive properties like high electron mobility, but it is decidedly not scalable.

Chemical Vapor Deposition (CVD) has been hotly pursued as a potentially scalable way to grow graphene on a metal substrate like copper or nickel. However, it has struggled with the step of peeling the graphene off of the metal substrate without ruining or contaminating it.

Now researchers at the Massachusetts Institute of Technology (MIT) and the University of Michigan have devised a way in which graphene can be grown directly onto an insulator like glass or silicon, eliminating the need to peel the graphene off of a metal substrate.

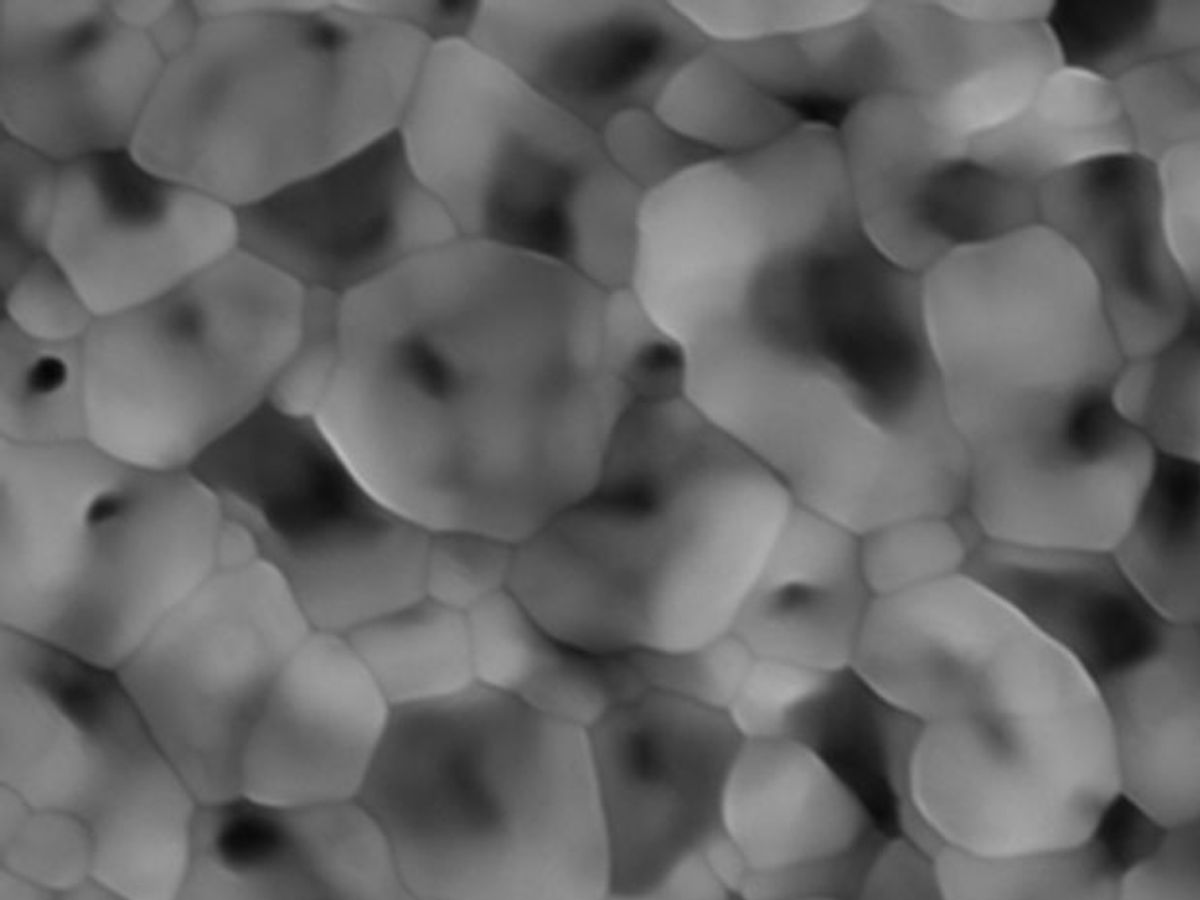

In the research, which was published in Nature’s Scientific Reports, the team was able to grow the graphene at the interface of nickel and silicon dioxide. They followed that step by mechanical removal of the nickel from the substrate.

This process eliminates the need for the wet etching steps that researchers from the National University of Singapore (NUS) employed in a similar process where graphene was grown at the interface between copper and a silicon substrate. Some researchers believe that the Singaporean method would suffer from contamination and wouldn’t be able to produce large, uniform films.

In contrast to this NUS method, the new process grows graphene on both sides of the nickel. In this way, it is possible to peel away the nickel and it will leave the graphene behind on top of the silicon substrate.

The researchers developed the method while working with a glass manufacturer so the aim was always to have a scalable production method.

“To meet their manufacturing needs, it must be very scalable,” says MIT's A. John Hart, in a press release. “We were inspired by the need to develop a scalable manufacturing process that could produce graphene directly on a glass substrate.”

While Hart cautions that the work is still at a preliminary stage due to a lack of consistent uniformity in the graphene films, it does open up some attractive potential applications.

Hart adds: “The ability to produce graphene directly on nonmetal substrates could be used for large-format displays and touch screens, and for ‘smart’ windows that have integrated devices like heaters and sensors.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.