Researchers at the University of Nebraska-Lincoln have discovered that the same principle that makes some pans non-stick can be exploited to improve the performance of solar cells.

In research published in the journal Nature Communications, the researchers have built a perovskite-based solar cell on a “non-wetting” plastic, making it 1.5 times as efficient at energy conversion as such cells had been previously.

Previously, the best way to get better efficiency in solar cells was to use single crystal material because it has fewer grains—the tiny pieces whose barriers trap and prematurely recombine electrons and holes—than polycrystalline materials. This made for a tough choice: single crystal materials, which are costly and difficult to produce, or polycrystalline materials, whose energy conversion efficiency is comparatively low.

But the Nebraska team has come up with a third choice: polycrystalline materials with a reduced number of grains. That had been tried before, with limited success; the size of the grains was locked in direct proportion to the thickness of the polycrystalline film. But their new production method, featuring the non-wetting surface, dramatically improved the area-to-thickness ratio. The researchers discovered that if they grew the polycrystalline material on this non-wetting surface, the grains grew up to eight times larger than the cell is thick.

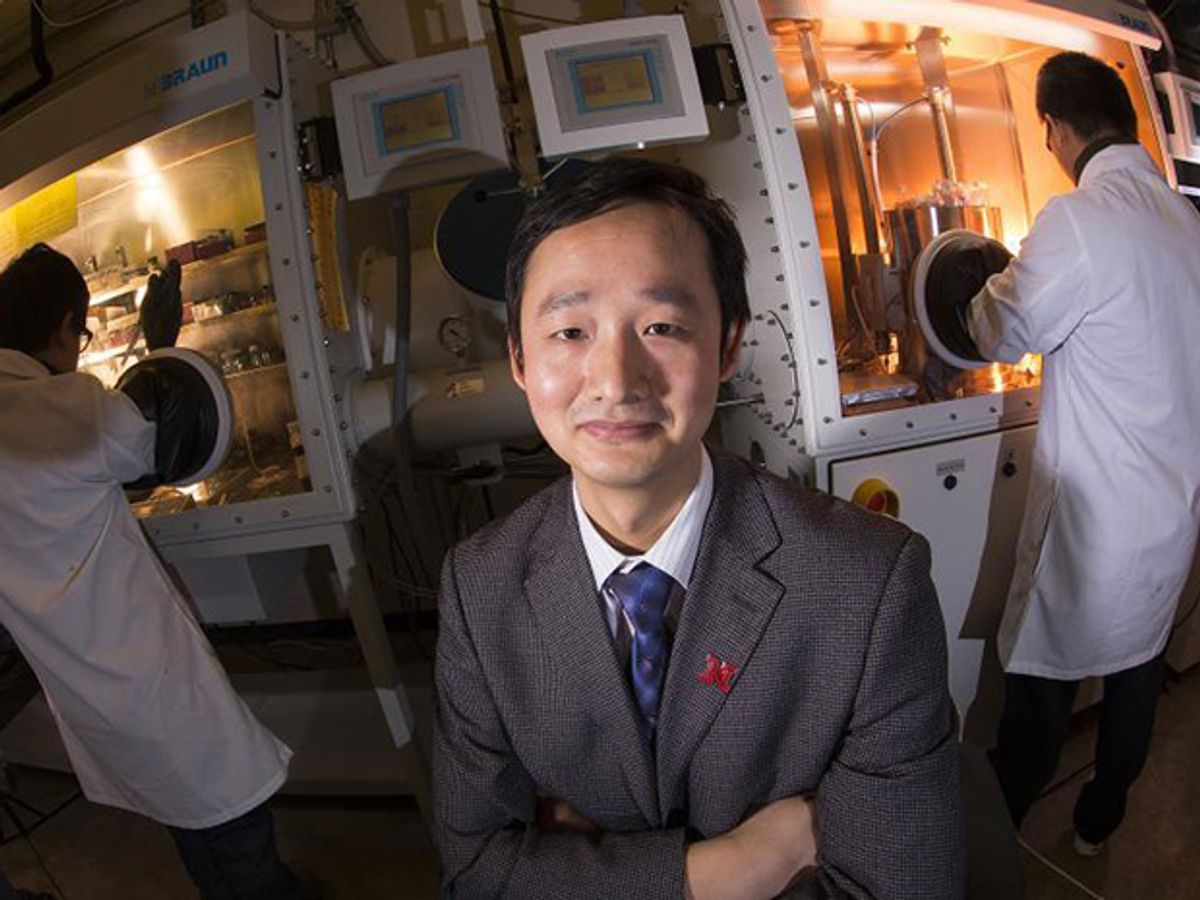

“We found that the difference is huge,” said Jingsong Huang, an associate professor of mechanical and materials engineering, in a press release. “When you have two small grains merge into a larger grain, what happens is that a boundary actually moves from (the middle of two grains) to the end of one or the other. How easily these boundaries move will determine how fast these grains can merge and grow.”

Huang added that “A non-wetting surface is slippery, like when you pour oil on a floor. It's easier for the grain boundary to move because we're reducing some of the drag force on it.”

The researchers believe that this use of a non-wetting surface can be exploited in other areas as well, such as aster transistors and more sensitive photodetectors.

Huang added: “When it comes to electronic properties, crystallinity and grain size determine a lot. So this is a simple method with a lot of potential applications.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.