Nuclear Reactor Renaissance

Nuclear reactor design is poised for a desperately needed revival. Here are seven contenders

More than half a century ago, the first commercial nuclear power reactors went critical in the United Kingdom and the United States. In the decades since, technology has brought us 3-billion-transistor chips, manned spaceflight, and violin-playing robots. Nevertheless, the basic design of commercial nuclear power reactors has changed not a whit. They seem to be trapped in a land that technology forgot.

Yes, conservatism can be a good thing, perhaps nowhere more so than in the design of nuclear reactors. Electric utilities aren’t known for daring, and you can’t reasonably expect them to risk several billion dollars on a reactor without a track record. On the other hand, you can’t pin hopes for a nuclear renaissance on designs that were fresh back when color TV and transatlantic jet travel were novelties. You need the promise of something much better, and no fewer than a dozen advanced reactor designs are in the running to offer it.

The backers of these designs are eyeing potentially enormous businesses, as “waking giant” countries China and India pursue major electrification schemes. In the United States and Europe, a significant shift to nuclear is far from assured, but several factors seem to be pushing that option, including climate change concerns and awareness of the hidden costs of fossil fuels.

The new reactor designs fall into three categories. First, there are the new light-water reactors, which aren’t radically different from what’s out there right now but add better safety features. Then there are the small modular reactors that produce less than 300 megawatts but can be scaled up. Need more power? Just add more modules to your plant. Finally, there are the really-out-there designs, known in the industry as Generation IV.

There are too many worthy, intriguing designs for us to describe here. So, after talking to a dozen nuclear experts, we simply chose seven reactor designs that struck us as the most innovative and interesting. We picked reactors of different kinds and at different development stages, including those that are only a hair’s breadth from regulatory approval and others that are literally still on the drawing board.

Did we leave out a new reactor design that you think beats all these here? Will new reactors reenergize the nuclear industry? Leave your comments below.

NEW + IMPROVED

Next-Gen Light-Water Reactors

To understand the new generation of nuclear reactors, you need to start with the basics. Think of a reactor as a tightly grouped array of thin, 4-meter-long, heat-emitting rods stacked in the center like a bunch of rigid metal asparagus. Surrounding those rods is a pressure vessel full of ordinary, or “light,” water. Each rod is filled with uranium fuel pellets, which when close to one another emit neutrons and lots of heat. The water in your basic thermal nuclear reactor needs to do three things: get hot; cool the nuclear fuel, which would otherwise overheat and cause a meltdown; and reduce the speed of the neutrons emitted by the nuclear reactions in that fuel. Here’s why. When a neutron hits a uranium nucleus, that nucleus then fissions into two smaller nuclei while emitting more neutrons. Then those neutrons hit other uranium nuclei, which fission, emitting neutrons that hit other nuclei, and so on. That’s a nuclear chain reaction. It seems counterintuitive, but the neutrons must be slowed—the technical term is “moderated”—to increase the rate at which they split the uranium nuclei they encounter in the fuel rods. Without the water to moderate them (graphite is another commonly used moderator), the neutrons would move too quickly for the uranium nuclei to absorb them, and the nuclear reaction would simply fizzle.

In a light-water reactor, ordinary water accomplishes both cooling and moderation. There are two main types. Pressurized-water reactors, or PWRs, are associated historically with Westinghouse Electric Corp., in which the vessel housing the fuel rods is kept at 160 atmospheres, so the water flowing past the core never turns to steam. The other kind are boiling-water reactors, pioneered for commercial uses by General Electric, which work, as the name suggests, by boiling the water that cools the reactor. Right now PWRs vastly dominate the nuclear landscape. The heat is used to produce steam that drives a turbine, which spins a dynamo to generate electricity. In both types, the steam is always produced by water flashing on extremely hot pipes.

Given their long history, light-water reactors won’t be going away anytime soon. One of the leading contenders for the next generation belongs (unsurprisingly) to Westinghouse, in the form of a souped-up PWR known as the AP1000. So far, it’s the only new PWR design that’s been approved by the U.S. Nuclear Regulatory Commission. (Although other countries have nuclear certification processes of their own, some borrow heavily from the NRC, which is influential internationally.) This new breed of PWR, which also includes a French model called an EPR, is known in the industry as Generation III or III+.

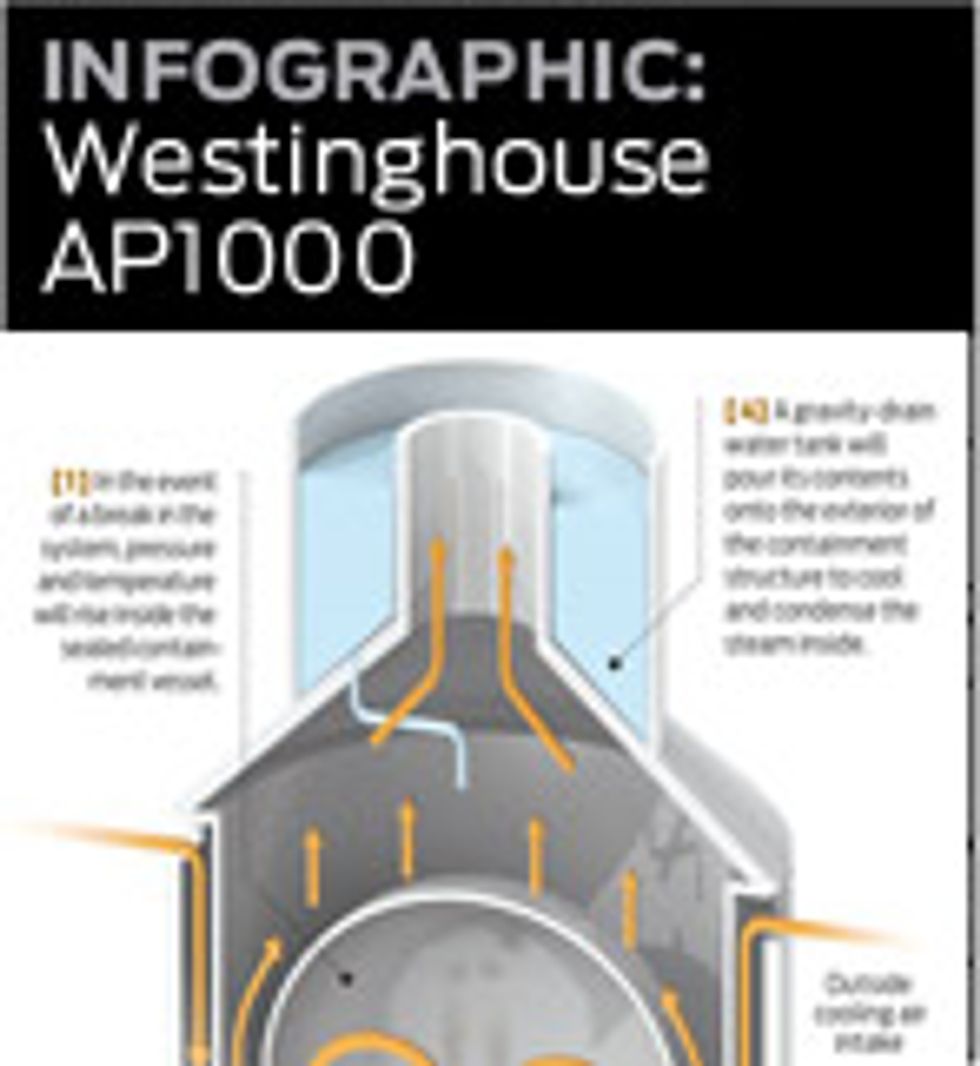

Westinghouse AP1000

Passive safety features will shut down this reactor without any power, pumps, or people

How it works:

The AP1000 core is similar to standard PWR cores: The fuel produces heat that turns water into steam, which drives a turbine.

Advantages:

The reactor’s designers have significantly improved the safety features on an otherwise standard PWR. Whereas conventional reactors rely on motor-powered valves and water pumps to deal with accidents, the amended AP1000 design has safety systems that rely on airflow, pressure changes, and gravity. For example, if a coolant pipe breaks, both the pressure and temperature rise inside the containment vessel [1]. Those changes trigger a water-flooding emergency system [2, 3, 4]. The water inside the sealed containment vessel heats up and turns into steam. The steam rises to the top, where the steel shell has been cooled by air circulating around the vessel. Thus cooled, the steam condenses back into water. This cycle reduces the pressure and temperature, and the nuclear chain reaction ends. Unlike other pressurized-water reactors, the AP1000 needs no safety features beyond the passive ones.

Disadvantages:

Water—particularly superheated water—corrodes metal, and so the pipes, joints, and other conduits must be periodically checked, maintained, and replaced. According to one estimate, the AP1000 will use as much water per megawatt as a regular PWR.

Time frame:

Westinghouse is building four AP1000s in China. Construction on Sanmen 1, which will be the world’s first operating AP1000, began in March of last year and should be completed in 2013. Three U.S. utilities have announced plans to build six AP1000 units, with one scheduled for commercial operation in 2016. However, construction can’t start until the NRC grants the reactor its final approval, which the agency says will not happen before mid-2011.

Manufacturer: Westinghouse Electric Co.

HQ: Cranberry Township, Pa.

Type: Pressurized-water reactor

Power: Thermal, 3415 MW; electric, 1117 MW

Fuel: Enriched uranium clad in fuel assemblies similar to those in ordinary PWRs

Refueling: Every 18 to 24 months

Coolant: Water

Moderator: Water

Waste: Spent fuel, consisting of leftover uranium 235 and other highly radioactive waste, similar to standard PWR waste.

EPR

Europe’s Evolutionary Power Reactor will be the world’s largest pressurized-water reactor

How it works:

An EPR core is similar to a standard PWR core, but larger.

Advantages:

The reactor is a descendant of the time-tested N4 and Konvoi reactors, the most modern reactors in France and Germany. An EPR’s turbines can be maintained while it is in service; its manufacturers claim this will make for very little downtime and a lifetime of 60 years. The Union of Concerned Scientists has referred to the EPR as the only new reactor design under consideration in the United States that “appears to have the potential to be significantly safer and more secure against attack than today’s reactors” [1]. The EPR also has the highest-ever efficiency (36 percent) in converting thermal energy into electric compared to other light-water reactors, whose efficiency typically runs at about 33 to 34 percent.

Disadvantages:

Some analysts have expressed doubts that the EPR is the world’s safest reactor. Their main concern is the spent fuel: The reactor’s higher burn-up rate makes the waste more radioactive, raising concerns about proliferation.

Time frame:

Four EPRs are now under construction: one each in Finland and France and two 1650-MW units in Taishan, China, which is already planning to build two more. The Finnish plant will be the world’s first EPR and the first Generation III+ reactor. A handful of U.S. utilities plan to build at least four EPR plants after the NRC finishes its review.

Manufacturer: Areva

HQ: Paris

Type: Pressurized-water reactor

Power: Thermal, 4500 MW; electric, 1650 MW

Fuel: The reactor can use 5 percent enriched uranium oxide clad in fuel rods similar to those of conventional PWRs. It can also use fuel with up to 50 percent mixed uranium plutonium oxide.

Refueling: Every 24 months, at most

Coolant: Water

Moderator: Water

Waste: Spent fuel, consisting of leftover uranium 235 and other highly radioactive waste.

SIZE MATTERS

Small Modular Reactors

One of the traditional selling points of nuclear power has been the high power levels available from a single plant—gigawatts rather than hundreds of megawatts. A single 1-gigawatt electrical plant could power about 1 million homes. Nowadays, though, the multibillion-dollar costs of building such a mammoth plant seem scary to investors. Smaller, modular reactors could provide scalable, emissions-free power at lower financial risk. They could also do this in remote areas off the grid. Yet another advantage is that one of the modules could be shut down for maintenance while others keep generating, avoiding long periods of downtime, which can be fantastically costly.

NuScale

A modular light-water reactor designed to replace coal- and gas-fired plants

How it works:

The nuclear fuel assemblies sit inside a long core vessel, which in turn is housed in a secondary containment vessel immersed in water. Unlike conventional light-water reactors, which require large pumps to circulate water through the core, the NuScale reactor is based on convection: The fuel heats up the water [1], which rises to the top of the core vessel, transfers the heat to steam generators, and cools down, descending to the bottom and repeating the cycle [2]. The steam drives electrical generators. After losing energy, the steam is cooled back into liquid in condensers, after which it flows again into the steam generators and the process repeats.

Advantages:

The design is basically a passive version of traditional light-water reactor technology. The cooling system relies on water convection alone and doesn’t require pumps. The plants are scalable—they can have a single reactor module or up to 24. Each module can be refueled individually, without affecting other modules. The modules can be largely manufactured off-site and transported by barge, truck, or rail, reducing construction time. Finally, the fuel and steam generator are housed inside a water-submerged steel vessel [3], which has a greater ability to withstand pressure and dissipate heat than the building that houses a traditional PWR.

Disadvantages:

In a full-size plant, the operator would have to manage, inspect, and maintain a dozen or more reactors. To be refueled, reactor vessels would have to be removed from the containment receptacle, transported to a servicing area using an overhead crane, then partially disassembled and refueled using remotely operated machines.

Time frame:

NuScale plans to apply for design certification with the NRC in early 2012. At about the same time, any utilities interested in building a plant would have to apply for construction and operation licenses. NuScale is in talks with several undisclosed utilities and expects a first plant to be operational in 2018.

Manufacturer: NuScale Power

HQ: Corvallis, Ore.

Type: Light-water reactor

Power: Thermal, 160 MW; electric, 45 MW for one reactor module. A full-scale plant would have 12 to 24 modules, or an electric power capacity of 540 to 1080 MW.

Fuel: Nearly 5 percent enriched uranium in 1.8-meter-long fuel assemblies similar to those used today in standard light-water reactors

Refueling: Every 24 months

Coolant: Water

Moderator: Water

Waste: Spent fuel, consisting of leftover uranium 235 and other highly radioactive waste, similar to standard PWR waste.

Hyperion Power Module

It could power a small town or a remote community off the electrical grid

How it works:

The Hyperion power module (HPM) is a fast reactor. This class of reactors does not need a moderator. In a standard PWR—known as a thermal reactor—water is essential, because it slows down neutrons so they can fission other uranium atoms and produce more neutrons. The advantage of using a moderator like water is that you can start a chain reaction using a relatively small mass of uranium fuel. By contrast, a fast reactor uses a larger mass of fuel, which releases many more neutrons. But here it’s no longer necessary to slow them to unleash a chain reaction. Also helping drive the process is the coolant, which in the HPM is a lead bismuth mixture [1]. Besides not slowing the neutrons, it transfers heat more efficiently to the turbine system.

Advantages:

The lead bismuth mixture is potentially safer than other liquid-metal coolants: Lead doesn’t react with air or water. Because it’s a fast reactor, the HPM doesn’t consume vast amounts of water, making it attractive for areas where water is scarce or unavailable. Uranium nitride fuel [2], which replaces standard uranium oxide, is less prone to cracking at high temperatures. The company claims that a vessel breach would simply leak liquid metal, which would immediately solidify instead of dispersing radioactive steam as a PWR would. The reactor would be built underground and have secondary coolant loops and control rods for extra safety [3, 4, 5].

Disadvantages:

Very few fast reactors have generated power commercially. Most are used for research and in military submarines. Hyperion’s uranium nitride fuel and its lead bismuth coolant have been individually tested in research reactors, but never together. The company has yet to demonstrate a fully operational prototype. Finally, there’s no guarantee that Hyperion will be around to make good on its promise to pick up the nuclear waste.

Time frame:

Hyperion says it already has more than 150 customers queued up, including mining and telecommunications companies in the Czech Republic, South Africa, the UK, and the United States, but these buyers will have to wait for the necessary licenses. Certification of the HPM reactor in the United States might take three to five years once the company submits an application.

Manufacturer: Hyperion Power Generation

HQ: Denver

Type: Liquid-metal-cooled reactor

Power: Thermal, 70 MW; electric, 25 MW

Fuel: Stainless steel fuel pins confine solid-ceramic uranium nitride pellets. The fuel is enriched to just under 20 percent. (Typical PWR fuel is 3 to 5 percent. The Nuclear Non-Proliferation Treaty defines 20 percent enrichment as the lower limit for “special nuclear material,” the level at which it is considered “weapons usable.”)

Refueling: None. Entire unit is replaced every 8 to 10 years

Coolant: Liquid lead bismuth (liquid-metal-cooled reactors are usually sodium cooled)

Moderator: No moderator (it’s a fast reactor)

Waste: Hyperion claims the HPM works as a disposable reactor: Instead of frequently replacing spent uranium with fresh fuel, refueling in this case means replacing the entire 20-metric-ton core with a brand new one. And Hyperion says it will take care of the used one.

WAVE OF THE FUTURE?

Generation IV Reactors

The most exotic designs, the Generation IV reactors, use new kinds of fuel and moderators. And fast-reactor designs do away with the moderator altogether. As a result, they require fuel with higher concentrations of fissile material (plutonium or uranium 235) than do light-water reactors. And a few promise to do something unprecedented—burn not just fuel but also the longer-lived nuclear waste products that have plagued nuclear energy since its inception. The Next Generation Nuclear Plant, a Generation IV design being considered by a consortium of U.S. companies, will likely be cooled by helium and moderated by graphite. The specific technology and leading companies will be announced early in 2011. Other, even more radical reactors include TerraPower’s traveling-wave reactor, which the company hopes to build and test in a little over a decade.

Toshiba 4S

The four S’s in the name stand for super, safe, small, and simple. Think of the reactor as a nuclear battery with a 30-year life

How it works:

The core, which is long and skinny [1], has a ring-shaped reflector that moves up slowly over time. This shield keeps neutrons contained in a focused area of the core, where the chain reaction takes place. As the ring rises, it slowly burns up the nuclear fuel. For harvesting the heat, the 4S reactor is configured with three loops. In the first, liquid-sodium metal circulates to cool the reactor core. Liquid sodium also circulates in the second loop, which transfers heat to a third, this one containing water and steam to drive a turbine. In the first and second loops, convection makes the liquid metal flow. To improve safety, electromagnetic pumps—with no moving parts—help with circulation [2]. The reactor is designed as a sealed cylindrical vault, which could be buried 30 meters underground to ensure safety against tornadoes and terrorists.

Advantages:

The reactor can sit mostly unattended for up to 30 years, in part because the liquid-sodium coolant doesn’t corrode the metal pipes and vessels of a reactor the way superheated water does. Also, because the reactor does not have to be pressurized, a pipe rupture would not be explosive. Instead, the molten sodium would merely seep. Like any fast reactor, the 4S could fission some of the longer-lived isotopes in the spent fuel, which would reduce to some degree the quantity of isotopes and also the overall volume of waste.

Disadvantages:

Sodium is extremely volatile and explodes on contact with water. One of the claimed benefits of this design—the fissioning of long-lived isotopes in the spent fuel—might actually be a weakness. Though the volume of waste product is reduced, the waste itself is much more radioactive and could conceivably be used to create dirty bombs.

Time frame:

In the United States, Toshiba has had preliminary meetings with the NRC and has submitted preapplication technical reports. The company expects to submit its design for review in late 2012. The NRC will not estimate when it could be approved. The 4S already has some interested parties, including the western Alaska city of Galena (population 599), which plans to apply for a construction license as soon as the NRC grants its approval.

Manufacturer: Toshiba

HQ: Tokyo

Type: Liquid-sodium-cooled fast reactor

Power: Thermal, 30 MW; electric, 10 MW

Fuel: Uranium enriched to about 19.9 percent (just below the 20 percent weapons-usable threshold); the uranium is mixed with zirconium and clad in steel.

Refueling: The reactor is sealed and never refueled. When its fuel is exhausted after 30 years, the entire reactor core would be returned to the manufacturer for disposal, and another one could take its place.

Coolant: Liquid sodium

Moderator: No moderator (it’s a fast reactor)

Waste: Spent fuel remains sealed in the core.

Next Generation Nuclear Plant

This Generation IV reactor is designed to produce electricity and also heat for industrial applications

How it works:

This reactor’s fuel consists of uranium particles known as tristructural isotropic, or TRISO, particles [1, 2]. Blocks or spheres containing the TRISO fuel and carbon are arranged into a nuclear core [3, 4], producing a chain reaction. Helium circulates through the core, removing heat. The helium drives a turbine directly, or it can generate steam to turn the turbines. Because the core consists of helium and graphite, it can withstand temperatures of 900 °C and even higher; pressurized-water reactors operate at about 300 °C.

Advantages:

The reactor’s higher temperature means it could provide heat to industrial processes such as petroleum refining, chemical manufacturing of plastics and fertilizers, and hydrogen production, thus helping to reduce carbon emissions and use of oil and natural gas. Despite its higher temperature, the reactor operates at one-fifth the power of a PWR. That reduced power density enhances overall safety. What’s more, additional heat naturally increases the carbon’s ability to absorb neutrons, so the carbon acts as a passive safety mechanism capable of shutting down the core. Fuel particles can withstand up to 1600 °C, so even in an accident the fuel would remain intact and limit fallout. High-temperature gas-reactor prototypes have been demonstrated in Germany and China.

Disadvantages:

Much testing is yet to be done. Fuel pellets need to be evaluated under heavy neutron bombardment, and so does the graphite that would form the core. The high-temperature materials to hold the helium—nickel-based superalloys—also must be fully characterized and tested in extreme conditions. Reactor physics must be simulated and validated. The reactor’s core would contain a lot of graphite that ideally would be recycled, a process that might prove costly.

Time frame:

In early 2011, the U.S. Department of Energy expects to choose between proposals from General Atomics and Westinghouse. Further design work should take 8 to 10 more years.

Manufacturer: Two designs, commissioned by the U.S. Department of Energy under the Next Generation Nuclear Plant program, are currently under development, one by a consortium led by General Atomics, in San Diego, and another by a consortium led by Westinghouse, in Cranberry Township, Pa.

Type: High-temperature gas-cooled reactor

Power: Thermal, 250 to 600 MW; electric, 112 to 270 MW

Fuel: Microscopic particles of uranium dioxide coated with carbon and silicon carbide. These spheres, known as tristructural isotropic, or TRISO, particles, are then mixed with lots of graphite and pressed into one of two possible geometries: spheres the size of tennis balls (the pebble-bed design) or sticks the size of a piece of chalk that are inserted into hexagonal graphite blocks (the prismatic design).

Refueling: The spent fuel is continuously replaced without shutting down the reactor. In the pebble-bed type, TRISO balls are removed from the bottom to have their fission levels measured, and new balls are added to the top. In the prismatic reactor, thousands of hexagonal blocks are stacked and their TRISO fuel sticks replaced periodically.

Coolant: Helium

Moderator: Graphite

Waste: The spent fuel consists of balls (in the pebble-bed reactor) and sticks (in the prismatic reactor) containing leftover uranium that didn’t undergo fission and other radioactive material; the waste would be stored in metal casks on-site.

TerraPower TP-1

This reactor produces a nuclear reaction wave that breeds and burns its own fuel—and lasts for decades

How it works:

A core vessel in the shape of a cylinder or parallelepiped is filled with mostly uranium 238, except for a relatively small amount of enriched uranium—the igniter—which is placed at one end of the vessel [1]. The igniter produces an initial flow of neutrons, which unleash a nuclear chain reaction. Because of the geometry of the vessel and the atomic properties of the uranium, the chain reaction travels through the core in a wavelike fashion, moving at a rate of a few centimeters per year and consuming the fuel from one end to the other, like the ember of a burning cigarette [2]. The wave consists of two reactions: The first breeds uranium 238 into plutonium 239; the other fissions the plutonium, producing more neutrons and heat. No new fissile material has to be added once the wave has started. If necessary, the reactor can be shut down using control rods; when the rods are removed, the wave naturally restarts.

Advantages:

The reactor doesn’t require enrichment or reprocessing, thereby reducing proliferation risks. It uses depleted uranium as fuel—a by-product of uranium enrichment that exists in large quantities and is unused. (It can also use spent fuel from existing light-water reactors.) One fuel load lasts for several decades, so the reactor can be sealed and won’t require refueling. Waste can remain in place after the reactor is decommissioned. A “mother reactor” could be used to start a breed-and-burn wave in a core, which is then shut down, transported to another location, and restarted there. The nuclear physics of the traveling wave has been extensively simulated in advanced computer models.

Disadvantages:

The design has not been fully tested. It would also depend on fast-reactor systems and materials that have not been used commercially. To start the wave, the reactor would need several tons of uranium enriched to about 10 percent, or almost double the enrichment level of light-water-reactor fuel. It would produce many tons of excess plutonium and other high-level radioactive wastes. The reactor has a high power density—a few hundred megawatts per cubic meter, compared to about 100 megawatts per cubic meter for a standard LWR—and would require liquid metal as coolant and cladding materials that have yet to demonstrate resistance to very-long-term heat and neutron exposure. Building and operating the first reactor would require cooperation from multiple entities and political support.

Time frame:

The project started in 2006. TerraPower will seek international cooperation to construct and operate the first reactor. The company expects to have a test reactor operational in 2020 and to push the technology to commercial scale in the late 2020s.

Manufacturer: Intellectual Ventures

HQ: Bellevue, Wash.

Type: Traveling-wave reactor

Power: Thermal, 900 to 1250 MW; electric, 350 to 500 MW. Designed as a modular reactor that can be combined into larger gigawatt-scale plantsFuel: The main fuel is depleted uranium, which can be found as uranium hexafluoride, a by-product of the uranium enrichment that is a part of current fuel production. (The reactor can also use spent fuel from light-water reactors.) The uranium 238 is transformed into uranium metal-alloy fuel and placed into rods that will form the core. The core needs an “igniter” consisting of enriched uranium (10 to 12 percent of fissile uranium 235); the igniter represents a relatively low percentage of the core’s weight.

Refueling: The reactor takes 40 to 50 years to consume fuel; no refueling is necessary during this period, but shuffling fuel rods to improve the burn-up rate might be required.

Coolant: Liquid sodium, which flows along the length of the fuel rods. Boron carbide control rods are placed within the current position of the wave, at locations where they can control power and reactivity.

Moderator: No moderator (it’s a fast reactor)

Waste: Leftover uranium fuel, excess plutonium, and other high-level radioactive waste. Waste can remain in place after reactor is decommissioned.

This article originally appeared in print as “Reactors Redux.”