Irradiation Nation

Can electron beams and x-rays make our food safe?

In the endless war between people and microorganisms, key battlegrounds are strung out all along the vast industrial chain that links farm, slaughterhouse, supermarket, and table. And it's not going so well at the moment for Homo sapiens.

Contamination at points along this chain triggers periodic infestations of bacteria, mold, and parasites that sicken up to 30 percent of the people who live in industrialized countries each year. The costs in medical treatments and lost productivity add up to billions of dollars a year, according to the Worldwatch Institute (Washington, D.C.). In the United States alone, food-borne pathogens afflict at least 76 million people per year, hospitalize 325 000, and kill more than 5000, according to the U.S. Centers for Disease Control and Prevention (Atlanta, Ga.).

In fact, last year, with two of the biggest meat recalls ever, was the worst on record for the United States. The facts suggest that we humans are merely warm, wet accommodations for the citizen-rulers of Planet Bacteria.

Now, though, humanity is rolling out the weapons of mass destruction. In the next few months, the U.S. Food and Drug Administration (FDA, Rockville, Md.) is expected to approve the use of gamma rays, electron beams, and X-rays to irradiate ready-to-eat foods like hot dogs, deli meats, frozen entrees, and snack foods. Unlike the European Union, which has approved irradiation only for spices and dried herbs, the U.S. government is on the verge of blessing irradiation for almost all food sold throughout the country, from wheat to meat. Already, you can saunter down the frozen-food aisle of any Piggly Wiggly supermarket in the United States and pick up ground beef that's been irradiated free of deadly bacteria.

At the same time, irradiation facilities are being built in Brazil, Saudi Arabia, Vietnam, and other countries to kill insects in tropical fruits like mangoes, papayas, and dates instead of using toxic, ozone-depleting methyl bromide. The treatment boosts product quality, extends shelf life from days to weeks, and saves money because produce can be shipped by boat instead of by faster, more expensive planes.

Still, even with these advantages, food irradiation faces some serious obstacles. No. 1, arguably, is consumer perception. Though many people appear to be gradually warming (so to speak) to the idea of irradiated foods, others are having a hard time reconciling the idea of safer food with the mushroom clouds that spring to mind when they hear the word "radiation."

Consumer advocates have protested the introduction of irradiated foods into grocery stores and school lunch programs (the United States Department of Agriculture [USDA, Washington, D.C.] approved irradiated ground beef for school lunch programs just this past May). While some of these objections are based on the (so far) unsubstantiated supposition that irradiated food causes cancer, many irradiation opponents, and food safety experts, too, question whether irradiation is the best way to fix the giant disease factory the global food industry has become.

Your friend, the ion

The enemy is a rogues' gallery of bacterial usual suspects, including Listeria monocytogenes, Campylobacter, Salmonella, and, especially, Escherichia coli O157:H7. According to the Centers for Disease Control and Prevention, every year E. coli O157:H7 kills hundreds of people in the United States, many of them children, the elderly, and others with less robust immune systems. The microbe thrives in the digestive tracts of warm-blooded animals like cows and usually infects meat through fecal contamination in the slaughterhouse.

The homicidal efficiency of modern microbes was revealed to heartbreaking effect in the infamous 1993 Jack-in-the-Box outbreak in the western United States. The concentrations of E. coli O157:H7 found in the restaurant chain's contaminated hamburgers never exceeded 15 organisms per gram of meat. In most cases, the concentrations were below one organism per gram. And yet they killed 4 children and sickened 732 people—195 badly enough to need hospitalization.

Food producers, the FDA, and the USDA responded to the outbreaks by shoring up detection of pathogens in the food supply. They designed a monitoring system, called the Hazard Analysis and Critical Control Point (HACCP, pronounced "hassip"), and installed it in about 6500 meat, poultry, and egg processing plants in the United States. Under a HACCP regime, points vulnerable to contamination are examined with various biological tests, including DNA probes and others based on antibody-antigen interactions. Still, countless pathogens make their way to the dinner table.

The use of ionizing radiation to kill bacteria and molds goes back almost half a century, to when the U.S. military started experimenting with gamma rays from the isotope cesium-137 to make Army rations safe. Today, though, gamma rays are being superseded for food safety by two other kinds of radiation: electron beams (e-beams) and X-rays.

In each case, the principle is the same, but the particle varies. With e-beams, it's electrons, of course; with X- or gamma rays, it's high-energy photons. As these particles strike the electrons in the molecules of irradiated food, they bounce like subatomic billiard balls, nailing outer-valence electrons in cascading collisions until their energy is finally dissipated. While these electrons ricochet around, the thing they are most likely to hit is a bacterium's double-stranded DNA molecules, which are comparatively huge.

The U.S. government is about to bless irradiation for almost all food sold throughout the country, from wheat to meat

When an electron rips through both strands of a bacterium's DNA, it ionizes atoms and disrupts molecular bonds, essentially breaking the DNA and killing the organism. A double-strand break is inevitably fatal, and a single-strand break at least weakens the bacterium, rendering it sterile. Unfortunately, this same ionizing action also produces highly reactive molecular fragments, called free radicals, that can affect the smell, taste, and appearance of irradiated food.

USDA does not mandate a minimum amount of radiation to render meat and poultry safe. Rather, the agency monitors results—the number of organisms in a given amount of product—and sets maximum safe radiation limits and labeling requirements. When E. coli O157:H7 is present in meat, its concentration is usually less than 100 organisms per gram, according to Daniel Engeljohn, USDA's Food Safety Inspection Service director of regulations and directives development staff. But because the microbe is so potent, a food processing company that wants to market ground beef as "free of E. coli O157:H7" must reduce the microbe's concentration 100 000-fold. That would require a minimum radiation dose of about 2 kilograys, or more than 20 million times the amount of a chest X-ray, resulting in no more than one organism per kilogram of product.

The same physics explains why gamma rays are useless for irradiating items like whole chickens. It turns out there is no speed at which a conventional conveyor could move to kill interior microbes without overexposing outer portions of the meat. The conveyor would have to go slowly enough to expose the interior chicken meat to at least the 1.5-kGy dose needed to kill Salmonella. Yet the conveyor must move fast enough to limit exposure to the outer portions to no more than 3 kGy.

Beyond that dose, the poultry would be transformed into a pinkish mass with an odor that has been described as resembling that of burnt feathers—a smell that is not eliminated by conventional cooking [see "Flavor Saver"].

The future of food irradiation seems to belong to e-beams and X-rays. E-beams provide fine dose control, for relatively thin foods like ground beef patties or foods with a uniform thickness of no more than 9 cm. X-rays penetrate deeper into food. They're fine for whole chickens and papayas, as well as pallets loaded with ready-to-eat foods like hot dogs, according to Chip Colonna, president of the GUARDiON Food Safety Division of the Belgium-based food irradiation company Ion Beam Applications SA (IBA North America, Memphis, Tenn.), which also owns several gamma ray facilities around the world [see "The Alpha and Omega of Gamma"].

Blasting bugs

For the current crop of e-beam food irradiators, we can thank President Ronald Reagan's dream of a missile defense program two decades ago. Reagan's Strategic Defense Initiative laid the foundation for what amounted to an "Electrons for Peace" program in the early 1990s to commercialize technology related to compact electron-beam accelerators. Linear accelerator technology developed by Titan Corp. (San Diego, Calif.) to obliterate incoming missiles and sniff out landmines is now used by a Titan spinoff, SureBeam Corp. (San Diego), to blast bugs and bacteria.

To get a glimpse of the technology in action, I traveled to SureBeam's sparkling new 2040-square-meter e-beam and X-ray irradiation facility in November 2002, two months before its official opening. Here, among the pork packers and food processors in Vernon, Calif., can be found the leading edge of food irradiation, in Los Angeles' industrial armpit [see "The Process of Irradiation (PDF)"].

Outside, the warm air was thick with the reek of slaughter coming from nearby buildings and dust kicked up by the endless stream of tractor-trailers that thunder past the SureBeam plant. Inside, the staging area, where the trucks will roll in and disgorge their contents, is chilly. Once the plant goes into production, it will accommodate the beef, poultry, and fresh produce that trucks unload here.

The goal is to turn a truck around in 75 minutes: unload it, irradiate the contents, and reload it. Tom Allen, a control systems guru who has designed PC assembly plants for IBM and Apple Computer and who is now SureBeam's vice president of systems engineering, integration, and field operations, estimates that up to 250 million pounds of food per year could be processed here by e-beam and another 100 million by X-ray.

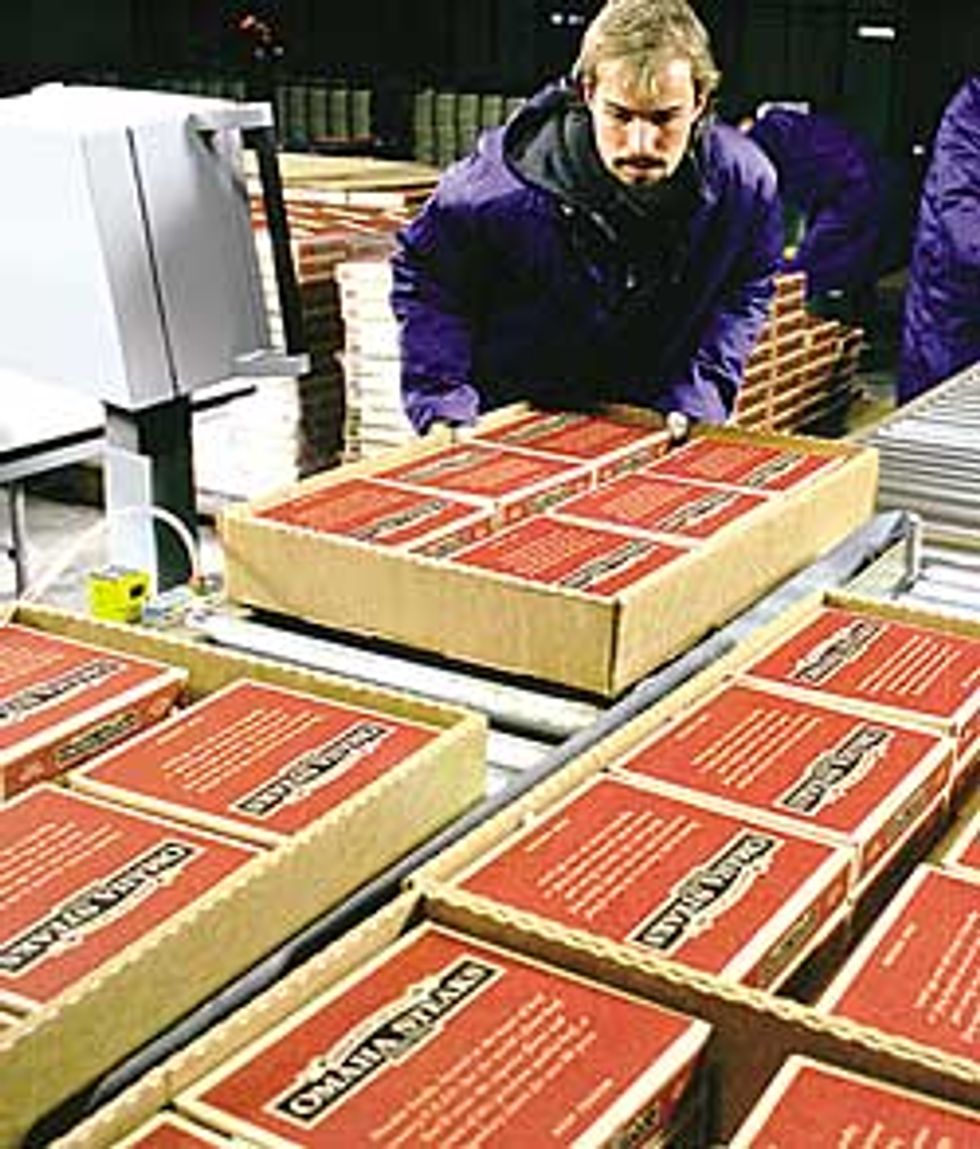

SureBeam charges by the facility or by the pound, either by selling and installing its systems as components of a customer's production lines or by irradiating foodstuffs sent to its service centers in Sioux City, Iowa, or Vernon. Customers include Huisken Meats, Cargill, Omaha Steaks, and the world's largest meat and poultry processor, Tyson Foods.

Business has boomed for SureBeam over the last year, with 5000 supermarkets now stocking ground meat it irradiates and hundreds of new stores coming aboard each month. Still, even charging an average of 5 cents per pound, the company has had to revise earnings estimates downward over the course of the year as the petition to approve irradiation for ready-to-eat foods languishes.

Chain-link fences divide the SureBeam facility in two, one side for e-beams, the other for X-rays. The company uses microwave linear accelerators, also known as microwave linacs or RF linacs, which accelerate electrons to 10 million electron volts (MeV) in the space of 1 meter. The process involves alternating electric fields in evacuated linac cavities shaped like hollow cylinders and lined with copper [see illustration, "The Scan Horn (PDF)"].

Generally, the electron-beam pulse produced by the linac must, like the beam in a conventional television set, be deflected with an electromagnet and scanned over the food. The beam emerges through an exit window—a 3-mm-thick piece of titanium foil—that is strong enough to maintain the vacuum yet thin enough that the beam can pass through without losing too many electrons as heat.

X-rays are produced by a similar (only 0.5-meter-long) accelerator and scanning system, but the scanned 5-MeV beam is aimed at an aluminum-backed, water-cooled tantalum target bolted at the front of the scan horn. X-rays are emitted in the so-called bremsstrahlung process as electrons decelerate when passing through the tantalum atoms. Scanning the electron beam over the target therefore also scans the X-ray beam.

The killing floor

A maze of thick concrete walls separates the irradiation chamber from the rest of the plant; the walls absorb X-rays not absorbed by food. Racks holding boxes of food dangle from overhead conveyors that follow a complex loop, from the loading area through the irradiation chamber and back out to the loading area.

To let us into the X-ray irradiation area, Allen has to insert two keys into a control panel, a fail-safe system not unlike the one submarine officers might use to initiate a ballistic-missile launch. The door clicks open and we enter.

Four hundred sensors are mounted throughout the maze, including motion detectors, radiation monitors, and limit switches that indicate the direction the food carriers are moving. They're all connected to a control console via an Ethernet. If you stumbled into the antechamber at the start of the maze while the system was running, yellow pressure mats on the floor would sense your presence, Allen assures me, and shut the system down. Redundancy is built into all the safety-critical systems. If for some reason the pressure mats fail, infrared sensor beams would detect a human presence and trigger a shutdown.

We follow the maze to two 15-kW X-ray accelerators. An overhead carrier will wend boxes of, say, papayas around the maze past the X-ray sources, where it will absorb most of the X-rays. Another carrier loaded with food running on a parallel track absorbs whatever X-rays pass through the papayas. The rest pass on to the wall opposite the two X-ray machines, which bears the ghostly burns of test exposures.

The Achilles' heel of X-ray systems is efficiency: energy conversion uses only about 8 percent of the total electron-beam energy. This low conversion rate makes an X-ray system less cost-effective and is the major obstacle to more widespread adoption. To help address the efficiency issue, the two 15-kW accelerators are slated to be replaced by a single, newly developed 150-kW accelerator this year. Soon SureBeam facilities in Vernon, and two being built for customers in Saudi Arabia and Vietnam, will feature the more powerful accelerators. These will process food at a higher rate: a 150-kW machine operating in X-ray mode can deliver 1.5 kGy to foodstuffs at a throughput rate of 3 kg/s.

Only half a loaf

Even though it is highly effective at killing bugs and bacteria, irradiation is at best only a partial solution to the problem of food safety. For example, radiation is useless against food-borne viruses, such as the Norwalk-like viruses, which account for millions of food poisoning cases worldwide. Viruses are just snippets of protein and so present a much smaller target to electrons than bacterial DNA.

To rid it of viruses, the food would have to be bombarded at such high doses as to render it inedible. And not all foods can be irradiated. Raw bean sprouts and leaf lettuces, for example, have thin, water-rich leaves that simply wilt from the process.

Then, too, lots can go wrong with food after it has been irradiated. Packages of food can be damaged and compromised during transport or while sitting on store shelves, where, because of longer shelf life imparted by irradiation, their chances of being mishandled increase. And irradiation does nothing to prevent contamination that occurs during preparation—those "All Employees Must Wash Hands" signs are posted in restaurant restrooms for good reason.

So food safety experts and consumer advocates alike question whether irradiation technology will ultimately result in a significantly safer food supply. Some irradiation opponents have tried to slow adoption of the technology by raising the alarm that ionizing radiation creates a unique chemical, 2-alkylcyclobutanone (2-ACB), whose ultimate impact on human health is unknown [see "Much Ado About 2-ACB,"].

But insisting that irradiated food might cause cancer, when in 50 years of testing no reliable studies have proven this so, takes the focus off the real issue, says Marion Nestle, professor of nutrition and food studies at New York University in New York City and the author, most recently, of Safe Food: Bacteria, Biotechnology, and Bioterrorism (University of California Press, 2003). She believes that irradiation is a late-stage technological Band-Aid that won't fix a food industry that refuses to clean up its act.

She insists that the epidemic of food-borne illness will abate only if there is a comprehensive HACCP regime for monitoring every point in the food chain, starting on the farm. The idea is to prevent animals from picking up those nasty pathogens in the first place and to ensure that no new ones get picked up along the way to the supermarket and, ultimately, the dinner table.

"The real question is: what kind of a food supply do we want? Do we want it cheap at the expense of expenses [for medical bills and lost productivity] later on down the line?" Nestle asks.

She argues that the economic benefits of a total food-chain HACCP regime would far outweigh the costs. USDA economists estimate that implementing HACCP will cost the meat and poultry industries alone over US $1 billion over the course of 20 years. But the $170 billion in medical costs and lost productivity that could be saved over 20 years—if HACCP achieved a 90 percent reduction in illnesses caused by the six most common pathogens—would obviously be worth the investment. Certainly, expanding HACCP to cover the entire food production system from farm to table would cost far more than $1 billion, but the potential savings would be proportionately higher, too.

Such an ambitious mandate would have to come from the U.S. government, however, and the political will required to institute such a sweeping program doesn't exist today at the FDA or the USDA. Bush administration appointees such as USDA's Undersecretary for Food Safety Elsa Murano advocate food irradiation. At the same time, as Nestle points out in the part of her book detailing the USDA's response to losing the HACCP-challenging case of Supreme Beef Processors Inc. v. USDA: "Under the administration of President George W. Bush, USDA officials appeared to be withdrawing support of HACCP, despite its evident effectiveness."

But with public awareness about the sorry state of the U.S. food system rising in the wake of massive recalls and the media attention to a disease-prone food supply commanded by Eric Schlosser's best-seller Fast Food Nation (Houghton Mifflin, 2001), high-profile articles by Michael Pollan for The New York Times Magazine, and Nestle's book, the worm might yet turn.