Finland’s Nuclear Waste Solution

Scandinavians are leading the world in the disposal of spent nuclear fuel

Here on Olkiluoto Island, the forest is king. Elk and deer graze near sun-dappled rivers and shimmering streams, and humans search out blueberries and chanterelle mushrooms. Weathered red farmhouses sit along sleepy dirt roads in fields abutting the woods. Far beneath the vivid green forest, deep in the bedrock, workers are digging the labyrinthine passages and chambers that they hope to someday pack with all of Finland’s spent nuclear fuel.

Posiva, the Finnish company building an underground repository here, says it knows how to imprison nuclear waste for 100 000 years. These multimillennial thinkers are confident that copper canisters of Scandinavian design, tucked into that bedrock, will isolate the waste in an underground cavern impervious to whatever the future brings: sinking permafrost, rising water, earthquakes, copper-eating microbes, or oblivious land developers in the year 25 000. If the Finnish government agrees—a decision is expected by 2012—this site will become the world’s first deep, permanent repository for spent nuclear fuel.

Of course, not everyone shares Posiva’s confidence. “It’s deep hubris to think you can contain it,” says Charles McCombie, executive director of the Association for Regional and International Underground Storage, based in Switzerland.

There’s more at stake here than the interment of 5500 metric tons of spent Finnish fuel. More than 50 years after the first commercial nuclear power plants went operational in the United Kingdom and the United States, the world’s 270 000 metric tons of spent nuclear fuel remain in limbo. After it gets swapped out of a reactor, utilities put it in specially designed pools, where chilled, circulating water absorbs the initial heat and radioactivity. After about five or six years, the fuel has cooled considerably, enabling utilities with limited pool space to load it into huge, million-dollar steel casks that are left to sit on concrete pads within guarded compounds.

The arrangement is far from ideal. The waste will emit harmful levels of radioactivity for thousands of years to come, and the casks are expected to last for a couple of hundred years, at most. The lack of a more permanent option is one of the biggest problems facing the global nuclear-power industry, which has been stalled for decades. But concerns about climate change have revived the prospects for nuclear power’s future growth, daring the industry to hope for a rebirth.

Years ago, almost every country with more than a few nuclear power plants was considering some sort of permanent repository. But politics has kept most of those plans at the paper stage. In the United States, the possibility of a permanent solution to the waste problem seems more elusive than ever: This past May, after two decades and US $9 billion, the Obama administration quietly ended a plan to build a repository beneath Yucca Mountain in Nevada. With the cancellation of Yucca, just two active repository projects for spent fuel are left: the Finnish one, which is called Onkalo, as well as a less advanced one in Sweden.

Onkalo’s underground tunnels won’t even begin to address the global situation. But they will do the next best thing. This project, estimated to cost 3 billion ($4.5 billion), will either demonstrate that the technical, social, and political challenges of nuclear waste disposal can be met in a democratic society, or it will scare other such countries away from the repository idea for decades to come.

So far, Posiva has carved out nearly 5000 meters of tunnels and shafts, excavated more than 100 000 cubic meters of rock, and collected rock samples from 53 deep boreholes. Over the next three years, it will try to prove to the government that its canisters and deep chambers will contain radioactive waste no matter what happens to Finland. If Posiva succeeds, the repository will open for business in 2020. A hundred years later, the final canister will be buried, and the tunnels will be filled in, covered up, and artfully abandoned to a cover of pine needles and mushrooms. Finland’s first nuclear era will be over.

It’s damp and drippy in Onkalo’s passageways. From the tunnel’s entrance, a low, guttural hum reverberates in the dark. Somewhere in the blackness, a machine is drilling and blasting its way steadily downward, and construction workers are scurrying in its wake to check the ceiling for rocks that have been jostled loose in the explosions. The jumbo-size drilling machines are trundling down a 5.5-meter-wide tunnel that grows by about 5 meters a day, says junior construction manager Karoliina Lehesvuori.

Lehesvuori, a perky young Finn dressed in the reflective yellow jacket and work boots that are the uniform of Onkalo staff, drives some visitors in an all-terrain vehicle through the winding access tunnel that coils downward into the bedrock. The car’s bright headlights illuminate the tunnel a few meters ahead, and its tires squish their way across the muddy floor. “We’re going down 290 meters now,” she alerts her passengers. The truck’s tires kick up a spattering of mud onto a parked drilling machine on the left. The burly rig is painted fire-engine red, and its mechanical tentacles dangle off its drilling arm. Farther down, in a space off to the side, two workers are passing planks through some scaffolding at the bottom of a big hole. They are fireproofing a ventilation shaft, one of the two places where oxygen can enter the tunnel. Lehesvuori leans out to greet the workers with a shout that carries over the soft droning of the machines hidden below.

From all sides, water glistens on the rock face and collects into mud on the tunnel floor. The droplets are leaking into the tunnel from tiny fractures in the rock, smaller than a millimeter, at a rate of about 20 liters per minute. In tunnel terms, that’s slow, and that’s good news. The behavior of the water in Onkalo is Posiva’s top concern. At each new depth, geologists extract slim rock cores in search of telltale “structures”—the fractures and crevices that determine how water moves in rock. So far, Onkalo appears to have uncharacteristically few structures, which explains why the tunnel is only damp and muddy rather than flooded with a torrent of water escaping from its high-pressure home in the rock.

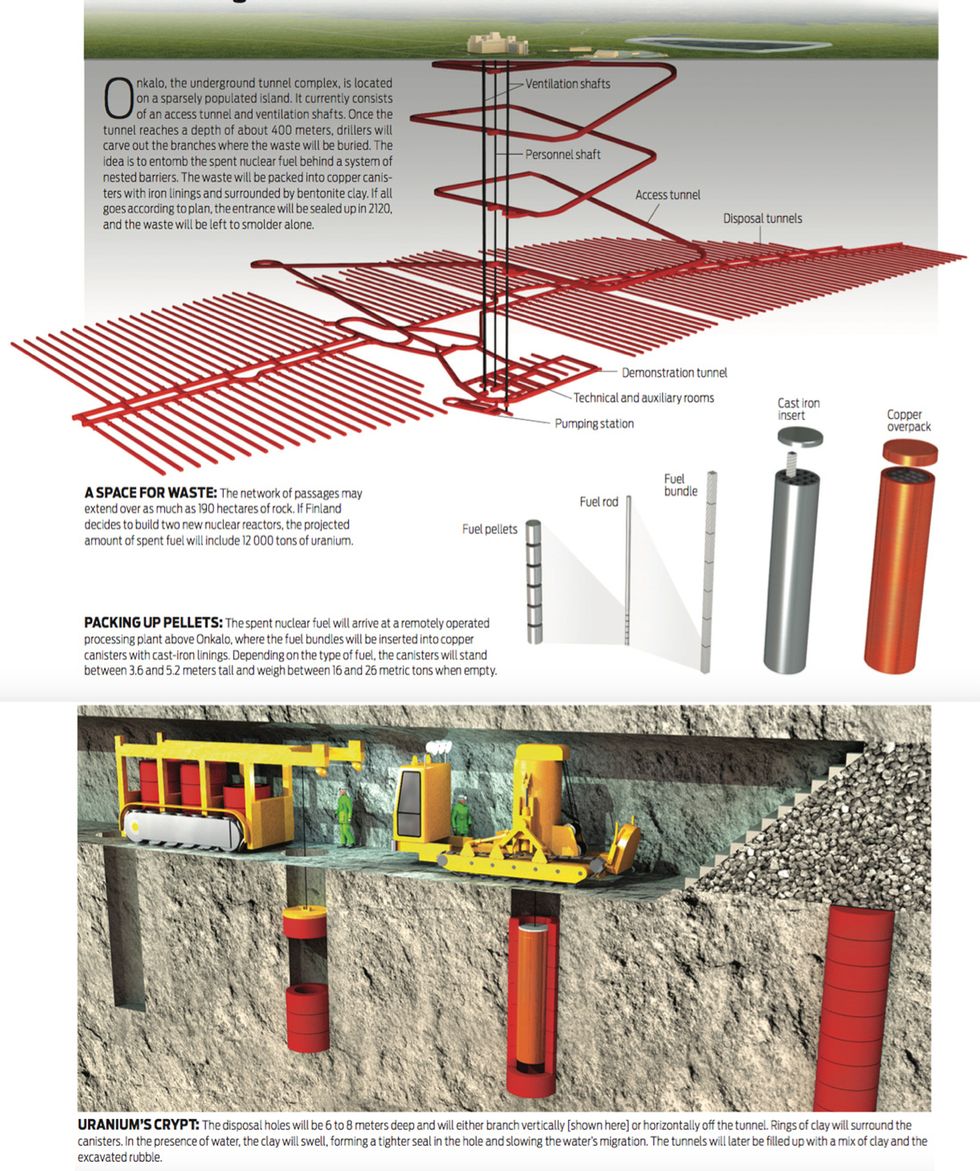

Water is the one agent that could seriously threaten Posiva’s design. What the company has bet on is a nested system of what it calls engineered barriers, which are enveloped by the natural barrier of gneiss bedrock. The first engineered container for the radioactive refuse is the copper burial cask, within which sits an iron insert. Each canister will then be buried in specially dug holes in the underground tunnel network and surrounded by a special clay—the second engineered barrier—through which water can slowly diffuse, but not flow. A century from now, after Finland’s last planned reactor has long been closed and its fuel has cooled, the tunnel’s empty spaces will be filled back up with rubble and clay, the final safeguard. A concrete slab will cover the entrance and, the designers hope, deter future adventurers.

In the nightmare scenario, water would somehow manage to reach the canisters, carrying with it bacteria that burrow through the clay and erode the metal containers. The fuel rods would become exposed to the clay, and the water would carry harmful radionuclides from the fuel back to the surface.

So far, though, the drillers haven’t struck any major fractures through which water might travel. So the work goes on. In three shifts, crews are working around the clock to deepen Onkalo. An arm of a drilling machine bores a hundred holes across the tunnel face, deposits dynamite into them, and the workers blast out a new layer of rubble. Then they clear the rubble and do it again. When they’ve finished, the diggers will have excavated a total of 7 kilometers of tunnels, shafts, and underground alleyways. The canisters will be deposited in neat rows of hollowed rock branching off the main tunnel, like the prongs of a TV antenna.

Down in the tunnel-in-progress, the enveloping hum of the invisible machines grows louder and more insistent. Then straight ahead, two specks of light appear. “Ah, we have to pull aside,” says Lehesvuori. “Another jumbo.” The growl becomes deafening as the giant red vehicle inches past, and then, gradually, the lights disappear and it’s back to black. The machine’s rumble fades to a distant murmur, and Lehesvuori pulls away from the wall to drive deeper into the nuclear void.

Finland might seem like an odd place to find cutting-edge nuclear waste technology. The country isn’t accumulating waste on a scale anywhere near that of other nuclear nations, such as France, Japan, the United Kingdom, and the United States. Nonetheless, Finland’s four reactors account for one-quarter of the country’s electricity production, making them the single largest contributor to Finland’s energy mix.

The origins of the Finnish nuclear program, in the 1970s, help to explain the country’s interest in disposal. In 1979, a reactor at the Three Mile Island plant, in Pennsylvania, experienced a partial core meltdown, forcing Finnish officials to take a harder look at their own fledgling nuclear effort. They’d been exporting their waste to the Soviet Union, but the Finns soon concluded that an environmental disaster was probably brewing on the other side of their shared border. So in 1983, the Finnish parliament mandated that the country’s two nuclear power plant companies set aside funds and begin planning immediately for disposal to begin in 40 years.

The first challenge for Posiva was to locate a spot where no one would ever be likely to dig a deep hole. T

“We needed a place that was very boring,” explains Johanna Hansen, Posiva’s research and development director. Rather than putting up elaborate signage to communicate with their far-future descendants, Hansen and her colleagues are betting that humanity will simply never want to dig here. They’d scanned the entire country for spots with no valuable metal deposits. They’d sampled groundwater all over Finland in search of the most saline, inhospitable locations. Pristine Olkiluoto passed muster. Olkiluoto’s residents, who were already sharing their island with two nuclear power plants—and were acutely aware of its lack of resources—welcomed the possibility of well-paying jobs for a century to come.

Their confidence that the project will be safe and well managed is unusual and not strongly supported by the historical record of government handling of other forms of high-level nuclear waste. In the Soviet Union, old nuclear submarines were simply abandoned along with their reactors and spent fuel in the Arctic Ocean. In the United States, at the decommissioned military reactor complex in Hanford, Wash., an estimated 1.67 trillion liters of low-level radioactive waste and more than 3 million liters of high-level waste have contaminated the soil and groundwater, and the radionuclides continue to leach into the nearby Columbia River. Unsettling lapses have also occurred at facilities in Sellafield in Cumbria, England; at the Savannah River in South Carolina; and at La Hague in northern France.

But in recent years, other than a couple of relatively small incidents in France, nuclear waste management has had a pretty good run. “The nuclear industry has an almost exemplary record in managing its material,” says Fergus Gibb, a professor of geochemistry at the University of Sheffield, in England. But, he cautions, “If there are instances of bad management, you probably don’t get to hear about them.”

To hedge against any gaps in their scholarship, a dramatic change in climate, or a total failure of design, Scandinavian engineers have agreed on what they insist is the most foolproof facility design possible. Mainly, they’ve agreed to mimic nature whenever they can. As Posiva’s communications manager, Timo Seppälä, puts it, “This is a design that forgives our mistakes.”

Starting in 2020, the fuel bundles will be hauled out from their temporary storage in pools near the reactors at Olkiluoto and Loviisa, Finland’s two nuclear power plant complexes. The fuel rods may be a half-century old by the time they reach the facility, after four years in a reactor and as many as 40 years in a pool. During its time underwater, the fuel’s radiation will have dropped to about 1 percent of what it was when it was first put in the pool.

Special transfer casks will deliver the bundles, still submerged in water, to the repository. The casks will slide off a truck bed into an encapsulation plant, and the doors to a fuel-handling cell will clamp shut, sealing the 1-meter-thick walls from the outside world. The room will be kept just under atmospheric pressure. That way, if a seal breaks, air will tend to rush in rather than out.

The outer lid of the transfer casks will slide open, and then the most dangerous part will begin. The fuel bundles will still be extremely radioactive, and they will be exposed to air for the first time since leaving the reactor core. With operators watching a video feed from radiation-tolerant cameras and through thick, lead-crystal windows, a remotely controlled arm will lift the fuel bundles out of the casks. A single bundle contains about 100 hollow zirconium rods, each as thick as a finger and filled with uranium pellets.

First, the bundles must dry. A cask of 12 fuel bundles could emit about 2 kilowatts of heat, so the smoldering rods tend to dry themselves pretty fast, according to Petteri Vuorio, the design engineer in charge of the encapsulation plant. But for final disposal, even a minuscule amount of water would be anathema. “This is the only place in the world where you have to worry about drying fuel bundles,” he says. So Posiva’s engineers have designed drying stations that will hold the fuel under a vacuum, lowering the pressure on the rods so that the water can boil off at about room temperature.

Once the bundles dry, a machine will select an assortment of varying ages and radioactivity levels to insert into the canisters. Including older fuel with more recent bundles will help ensure that the canisters won’t accidentally cause the water in the bedrock to boil. Each canister consists of an iron tube that sits snugly inside a copper shell. Here, the Finns draw inspiration from their geology. Copper exists naturally in the bedrock here, which means it has withstood millions of years without suffering anything worse than turning green. In the nuclear fuel industry, that’s as good an existence proof as any.

Then it’ll be time to seal the canisters. The 5-meter-long cylinders will move on a track that guides them through the facility, allowing them to swivel and turn to meet each station. Each canister will rotate precisely on its track as high-velocity electrons weld the lid to the top of the canister without weakening the surrounding material. “It is quite demanding to have so much accuracy so that the weld is perfect,” says Vuorio. He says his engineers are still working out the details of how to lift and rotate the untouchable, bulky 26-metric-ton canisters during the welding. All in all, they’ll need to create and package about 3000 canisters as flawlessly as possible.

The canister will then roll to the next station, where X-ray beams will search out flaws in the welding, and ultrasonic and eddy-current inspection systems will analyze the surface for tiny aberrations. In eddy-current testing, a coil carrying alternating current generates a magnetic field when brought close to the copper. The field induces eddies of current whose flows change in the presence of surface imperfections. If a canister passes the tests, it will glide into an elevator at one end of the building that will carry it down a shaft, straight into the repository.

As much as 12 000 metric tons of uranium—alongside the other isotopes and zirconium rods—may eventually find their way into Onkalo. The facility will pack away at least 27 000 fuel bundles, and more may follow from Finland’s projected nuclear power production through 2080.

After the canisters are deposited, stacks of bentonite clay blocks will be dropped in to encircle each canister like pineapple rings, to fill in the gaps between the wall of a hole and the copper. Should water approach, the bentonite would swell, forming an even tighter envelope around the rock and the canisters. Any water would diffuse very slowly through the sludgy gray clay to the copper and the fuel pellets inside. “We’re talking millions of years for water to get through clay,” says Michael Apted, an executive consultant for Monitor Scientific, in Denver, and chairman of an advisory group to Finland’s nuclear safety authority, STUK. Bentonite also holds up well over time: In Hungary, coal miners stumbled on 8-million-year-old wooden tree trunks buried in a clay shell.

Once the canisters are in place, the tunnels will be filled with a blend of more bentonite and excavated rock. “We know that the bedrock is 1.8 billion years old and hasn’t changed since it was created,” says Hansen. “We must try to maintain the bedrock as it was, so that the conditions return to how they were before we started disposal.” Now, however, the bedrock will contain the highest local concentration of uranium in the world, and the new geology must hold strong for a period of time that’s almost absurdly beyond human reckoning.

But in repository design, everything is relative. A thousand centuries may seem like a long time, but for nuclear waste it’s just the beginning. Spent nuclear fuel is mostly uranium-238, with a half-life of 4.46 billion years. The longer the half-life of the isotope, the less radioactivity it emits—but that’s not the full story. Some harmful isotopes are less likely to attach themselves to clay or rock, and therefore they are more likely to move around. “In terms of the stuff that could make it out in hundreds of thousands of years, iodine-129 and cesium-135 would be on the list,” says John Kessler, a spent-fuel-management expert at the Electric Power Research Institute, in Charlotte, N.C. “But over a million years, the uncertainties are pretty big.”

The next logical question might be whether all this potency might in fact be useful. In other words, should we regard spent nuclear fuel as an incorrigible health hazard or as a potential resource? Not everyone sees spent fuel as waste—the UK, France, and now Japan, for example, reprocess much of their waste into usable fuel, at considerable cost.

Technical breakthroughs may end up driving down the cost of reprocessing the spent fuel, in which the uranium and plutonium are separated from the remaining waste and potentially reused. “It becomes an economic competition between mining and drilling technology and the technology of reprocessing to see who is going to drive the cost down,” says Charles Forsberg, a research scientist at MIT and the executive director of the MIT Nuclear Fuel Cycle Project.

Hans Forsström, the director of the Nuclear Fuel Cycle and Waste Technology Division at the International Atomic Energy Agency, doesn’t see it that way. He argues instead that building repositories is a question of public acceptance, not a question of money. By Forsström’s estimate, the cost of spent nuclear fuel disposal is between 10 and 20 percent of the cost of producing the electricity, which he thinks is not all that much. “There’s this intergenerational responsibility, that those who profited from using the waste should take care of the waste,” Forsström says.

Finland has made its commitment. It’s not a country prone to fads or rapid change. Down the road from Onkalo, the town of Rauma is a 500-year-old testament to Finnish impassivity. This UNESCO world heritage site is a cobblestone wonderland of wooden houses gussied up with lacy trim. While most of the world’s 15th-century towns burned to the ground long ago, this one still provides homes and shelter for businesses.

Here, though, 500 years is hardly a heartbeat. In as little as 20 000 years, Finland may enter an ice age, and advancing ice sheets kilometers thick could carve out the rock and force more water into its fractured depths. The liquid may then diffuse through the bentonite barrier, eat through the copper, and carry off still-hot radionuclides. No one can be sure.

But maybe nobody will be here to care. In 1000, 10 000, or 100 000 years, it might not be unreasonable to think our descendants will have abandoned this toxic land for a cozier alternative, on space pods or newly colonized planets. Where once there were humans, now hermaphroditic fish and finned flamingos may slither through our poisonous landscapes. Or perhaps evolution’s charge will have delivered beings who are healthier, cuter, and more intelligent than the ones designing today’s disposal systems. Or evolution may go in the opposite direction and cockroaches will reign supreme, just as we always suspected they might.

Then perhaps, as one epoch slides into the next, whoever remains will come to Onkalo to study, with great curiosity, their distant ancestors’ struggle with the dark side of Earth’s bounty.

A correction to this article was made 15 December 2009.