Dismantling Fukushima: The World’s Toughest Demolition Project

Taking apart the shattered power station and its three melted nuclear cores will require advanced robotics

A radiation-proof superhero could make sense of Japan’s Fukushima Daiichi nuclear power plant in an afternoon. Our champion would pick through the rubble to reactor 1, slosh through the pooled water inside the building, lift the massive steel dome of the protective containment vessel, and peek into the pressure vessel that holds the nuclear fuel. A dive to the bottom would reveal the debris of the meltdown: a hardened blob of metals with fat strands of radioactive goop dripping through holes in the pressure vessel to the floor of the containment vessel below. Then, with a clear understanding of the situation, the superhero could figure out how to clean up this mess.

Unfortunately, mere mortals can’t get anywhere near that pressure vessel, and Japan’s top nuclear experts thus have only the vaguest idea of where the melted fuel ended up in reactor 1. The operation floor at the top level of the building is too radioactive for human occupancy: The dose rate is 54 millisieverts per hour in some areas, a year’s allowable dose for a cleanup worker. Yet, somehow, workers must take apart not just the radioactive wreck of reactor 1 but also the five other reactors at the ruined plant.

This decommissioning project is one of the biggest engineering challenges of our time: It will likely take 40 years to complete and cost US $15 billion. The operation will involve squadrons of advanced robots, the likes of which we have never seen.

Nothing has been the same in Japan since 11 March 2011, when one of history’s worst tsunamis flooded Fukushima Daiichi, crippled its emergency power systems, and triggered a series of explosions and meltdowns that damaged four reactors. A plume of radioactive material drifted over northeast Japan and settled on towns, forests, and fields, while plant workers scrambled to pour water over the nuclear cores to prevent further radioactive releases. Nine months later, the Tokyo Electric Power Co. (TEPCO), the utility company that operates the plant, declared the situation stable.

Stability is a relative concept: Although conditions at Fukushima Daiichi aren’t getting worse, the plant is an ongoing disaster scene. The damaged reactor cores continue to glow with infernal heat, so plant employees must keep spraying them with water to cool them and prevent another meltdown. But the pressure vessels and containment vessels are riddled with holes, and those leaks allow radioactive water to stream into basements. TEPCO is struggling to capture that water and to contain it by erecting endless storage tanks. The reactors are kept in check only by ceaseless vigilance.

TEPCO’s job isn’t just to deal with the immediate threat. To placate the furious Japanese public, the company must clean up the site and try to remove every trace of the facility from the landscape. The ruin is a constant reminder of technological and managerial failure on the grand scale, and it requires a proportionally grand gesture of repentance. TEPCO officials have admitted frankly that they don’t yet know how to accomplish the tasks on their 40-year road map, a detailed plan for decommissioning the plant’s six reactors. But they know one thing: Much of the work will be done by an army of advanced robots, which Japan’s biggest technology companies are now rushing to invent and build.

Here’s some more bad news: Chernobyl and Three Mile Island, the only other commercial-scale nuclear accidents, can’t teach Japan much about how to clean up Fukushima Daiichi. The Chernobyl reactor wasn’t dismantled; it was entombed in concrete. The Three Mile Island reactor was defueled, but Lake Barrett, who served as site director during that decommissioning process, says the magnitude of the challenge was different. At Three Mile Island the buildings were intact, and the one melted nuclear core remained inside its pressure vessel. “At Fukushima you have wrecked infrastructure, three melted cores, and you have some core on the floor, ex-vessel,” Barrett says. Nothing like Fukushima, he declares, has ever happened before.

Barrett, who is now a consultant for the Fukushima cleanup, says TEPCO is taking the only approach that makes sense: “You work from the outside in,” he says, dealing with all the peripheral problems in the buildings before tackling the heart of the matter, the melted nuclear cores. During the first three years of the cleanup, TEPCO has been surveying the site to create maps of radiation levels. The next step is removing radioactive debris and scrubbing radioactive materials off walls and floors. Spent fuel must be removed from the pools in the reactor buildings; leaks must be plugged. Only then will workers be able to flood the containment structures so that the melted globs of nuclear fuel can safely be broken up, transferred to casks, and carted away.

Many of the technologies necessary for the decommissioning already exist in some form, but they must be adapted to fit the unique circumstances of Fukushima Daiichi. “It’s like in the 1960s, when we wanted to put a man on the moon,” says Barrett. “We had rocketry, we had physics, but we had never put all the technologies together.” Just as with the moon shot, there is no guarantee that this epic project can be accomplished. But faced with the wrath of the Japanese people, TEPCO has no choice but to try.

Graphic: How To Take Apart A Melted-Down Reactor

To begin the first step—inspection—TEPCO sent in robots to map the invisible hot spots throughout the smashed reactor buildings. The first to arrive were the U.S.-made PackBot and Warrior, hastily shipped over from iRobot Corp. of Bedford, Mass. But Japan is justly proud of its own robotics industry, so the question arose, Why didn’t TEPCO have robots ready to respond in a nuclear emergency? Yoshihiko Nakamura, a University of Tokyo robotics professor, has the dispiriting answer. The government did fund a program on robotics for nuclear facilities in 2000, following a deadly accident at a uranium reprocessing facility. But that project was shut down after a year. “[The government] said this technology is immature, and it is not applicable for the nuclear systems, and the nuclear systems are already 100 percent safe,” Nakamura explains. “They didn’t want to admit that the technology should be prepared in case of accident.”

Still, some roboticists in Japan carried on their own research despite the government’s indifference. In the lab of Tomoaki Yoshida, a roboticist at the Chiba Institute of Technology, near Tokyo, robots have learned to crawl over rubble and to climb up and down steps. These small tanks roll on a flexible series of treads, which can be lifted or lowered individually to allow the bot to manage stairs.

After the Fukushima accident, Yoshida’s academic research became very relevant. With seed money from the government, he constructed two narrow metal staircases proportioned like the 5-floor staircases inside the Fukushima Daiichi reactor buildings. This allowed Yoshida to determine whether his bots could navigate those cramped stairs and tight turns. His acrobatic Quince robots proved themselves able, and after hundreds of tests they received TEPCO’s clearance for field operations. In the summer of 2011, the Quince bots became the first Japanese robots to survey the reactor buildings.

The Quinces were equipped with cameras and dosimeters to identify radioactive hot spots. But the robots struggled with a communication issue: The nuclear plant’s massive steel and concrete structures interfere with wireless communication, so the Quinces had to unspool cables behind them to receive commands and transmit data to their operators. The drawback of that approach soon became apparent. One Quince’s cable got tangled and damaged on the third floor of reactor 2, and the lonely bot is still sitting there to this day, waiting for commands that can’t reach it.

Slideshow: Meet the Robots of Fukushima Daiichi

Back at Yoshida’s lab, where modest bunk beds bespeak the dedication of his students, the team is currently working on a new and improved survey bot named Sakura. To guard against future tangles, Sakura not only unspools cable behind, it also automatically takes up the slack when it changes direction. It’s waterproof enough to roll through puddles, and it can carry a heavy camera capable of detecting gamma radiation. The bot can tolerate that radiation: Yoshida’s team tested its electronics (the CPU, microcontrollers, and sensors) and found that they’re radiation-tolerant enough to perform about 100 missions before any component is likely to fail. However, the robot itself becomes too radioactive for workers to handle. Sakura must therefore take care of itself: It recharges its batteries by rolling up to a socket and plugging itself in.

The second step in the Fukushima decommissioning is decontamination, because only when that is complete will workers be able to get inside to tackle more complex tasks. The explosions that shattered several of the reactor structures sprayed radioactive materials throughout the buildings, and the best protective suits for workers in hot zones are of little use against the resulting gamma radiation—a worker would have to be covered from head to toe in lead as thick as the width of a hand.

After the accident, the Japanese government called for robots that could work on decontamination, and several of Japan’s leading companies rose to the challenge. Toshiba and Hitachi have designed robots that use jets of high-pressure water and dry ice to abrade the surfaces of walls and floors; the robots will scour away radioactive materials along with top layers of paint or concrete and vacuum up the resulting sludge. But the robots’ range is defined by their own communication cables, and they can carry only limited amounts of their cleaning agents. Another bot, the Raccoon, has already begun nosing across the floor in reactor building 2, trailing long hoses behind it to supply water and suction.

To clear a path for the robotic janitors, another class of robots has been invented to pick up debris and cut through obstacles. The ASTACO-SoRa, from Hitachi, has two arms that can reach 2.5 meters and lift 150 kilograms each. The tools on the ends of the arms—grippers, cutting blades, and a drill—can be exchanged to suit the task. However, Hitachi’s versatile bot is limited to work on the first floor, as it can’t climb stairs.

Removing spent fuel rods is the third step. Each reactor building holds hundreds of spent fuel assemblies in a pool on its top floor. These unshielded pools, perfectly safe when filled with water, became a focus of public fear during the Fukushima Daiichi accident. After reactor building 4 exploded on 15 March, many experts worried that the blast had damaged the structural integrity of that building’s pool and allowed the water to drain out. The pool was soon determined to be full of water, but not before the chairman of the U.S. Nuclear Regulatory Commission had caused an international panic by declaring it dry and dangerous. The reactor 4 pool became one of TEPCO’s urgent decommissioning priorities, not only because it’s a real vulnerability but also because it’s a potent reminder of the accident’s terrifying first days.

The process of emptying that pool began in November 2013. TEPCO workers use a newly installed cranelike machine to lower a cask into the pool, then long mechanical arms pack the submerged container with fuel assemblies. The transport cask, fortified with shielding to block the nuclear fuel’s radiation, is lowered to a truck and brought to a common pool in a more intact building. The building 4 pool contains 1533 fuel assemblies, and moving them all to safety is expected to take a year. The same procedure must be performed at the highly radioactive reactors 1, 2, and 3 and the undamaged (and less challenging) reactors 5 and 6.

Slideshow: Living with Fear in Fukushima

Containing the radioactive water that flows freely through the site is the fourth step. Every day, about 400 metric tons of groundwater streams into the basements of Fukushima Daiichi’s broken buildings, where it mixes with radioactive cooling water from the leaky reactor vessels. TEPCO treats that water to remove most of its radioactive elements, but it can’t be rendered entirely pure—and as a result local fishermen have protested plans to release it into the sea. To store the accumulating water, TEPCO has installed more than 1000 massive tanks, which themselves must be monitored vigilantly for leaks.

TEPCO hopes to stop the flow of groundwater with a series of pumps and underground walls, including an “ice wall” made of frozen soil. Still, at some point the Japanese public must grapple with a difficult question: Can the stored water ever be released into the sea? Barrett, the former site director of Three Mile Island, has argued publicly that the processed water is safe, as contamination is limited to trace amounts of tritium, a radioactive isotope of hydrogen. Tritium is less dangerous than other radioactive materials because it passes quickly through the body; after it’s diluted in the Pacific, Barrett says, it would pose a negligible threat. “But releasing that water is an emotional issue, and it would be a public relations disaster,” he says. The alternative is to follow the Three Mile Island example and gradually dispose of the water through evaporation, a process that would take many years.

TEPCO must also plug the holes in the reactor vessels that allow radioactive cooling water to flow out. Many of the leaks are thought to be in the suppression chambers, doughnut-shaped structures that ring the containment vessel and typically hold water, which is used to regulate temperature and pressure inside the pressure vessel during normal operations. Shunichi Suzuki, TEPCO’s general manager of R&D for the Fukushima Daiichi decommissioning, explains that one of his priorities is developing technologies to find the leak points in the suppression chambers.

Sidebar: Selling Nuclear Safety to the Public

“There are some ideas for a submersible robot,” Suzuki says, “but it will be very difficult for them to find the location of the leaks.” He notes that both the suppression chambers and the rooms that surround them are now filled with water, so there’s no easy way to spot the ruptures; it’s not like finding the hole in a leaky pipe that’s spraying water into the air. Among the robot designs submitted by Hitachi, Mitsubishi, and Toshiba is one bot that would crawl through the turbid water and use an ultrasonic sensor to find the breaches in the suppression chambers’ walls.

If robots prove impractical, TEPCO may take a more heavy-handed approach and start pouring concrete into the suppression chamber or the pipes that lead to it. “If it’s possible to make a seal between the containment vessel and the suppression chamber, then the leaks don’t matter,” Suzuki says. One way or another, TEPCO hopes to have all the leaks stopped up within three years. Sealing the leaks is a necessary precondition for the final and most daunting task.

Removing the three damaged nuclear cores is the last big step in the decommissioning. As long as that melted fuel glows inside reactors 1, 2, and 3, Fukushima Daiichi will remain Japan’s ongoing nightmare. Only once the fuel is safely packed up and carted away can the memory begin to fade. But it will be no easy task: TEPCO estimates that removing the three melted cores will take 20 years or more.

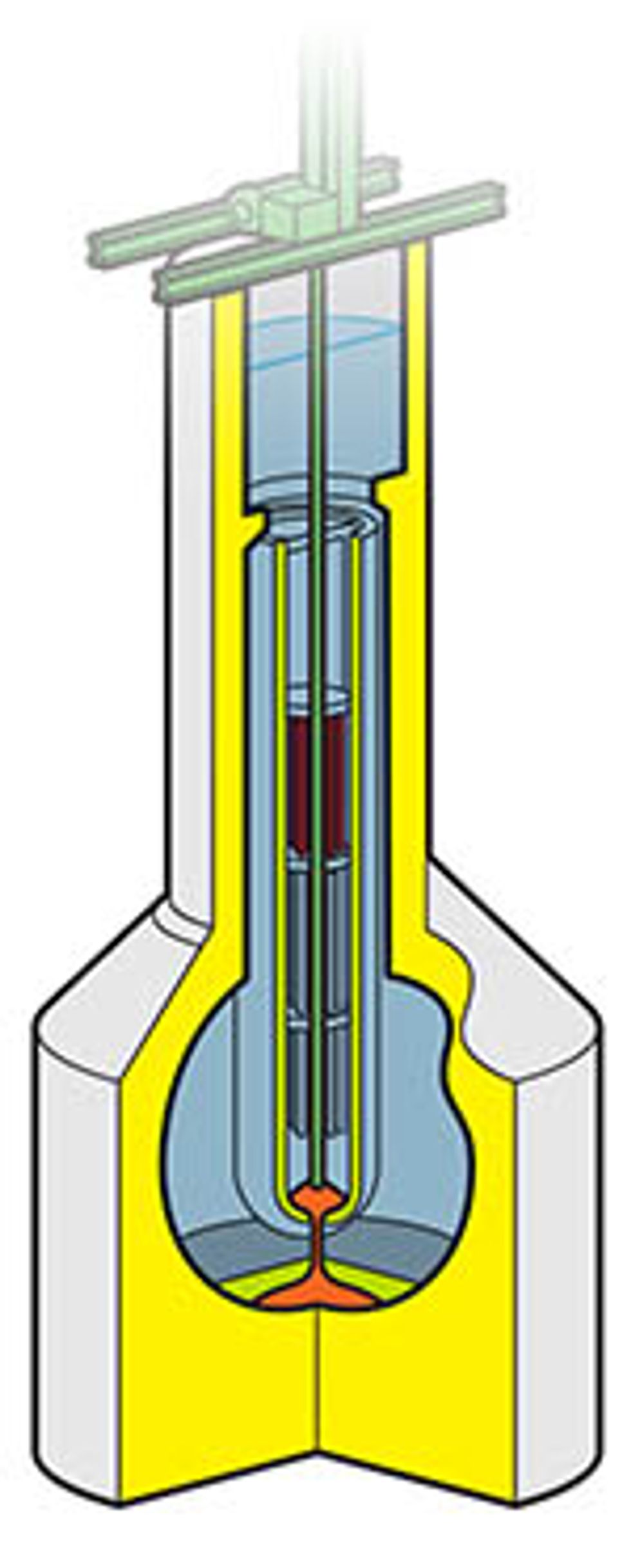

First, workers will flood the containment vessels to the top so that the water will shield the radioactive fuel. Then submersible robots will map the slumped fuel assemblies within the pressure vessels; these bots may be created by adapting those used by the petroleum industry to inspect deep-sea oil wells. Next, enormously long drills will go into action. They must be capable of reaching 25 meters down to the bottoms of the pressure vessels and breaking up the metal pooled there. Other machines will lift the debris into radiation-shielded transport casks to be taken away.

Making the task more complicated is the design of the reactors. They have control rods that project through the bottom of the pressure vessels, and the entry point for each of those control rods is a weak spot. Experts believe that most of the fuel in reactor 1, and some in reactors 2 and 3, leaked down through those shafts to pool on the floor of the containment vessel below. To reach that fuel, some 35 meters down, TEPCO workers will have to drill through the steel of the pressure vessel and work around a forest of wires and pipes.

Before TEPCO can even develop the proper fuel-handling tools, Suzuki says, the company must get a better understanding of the properties of the corium—the technical term for the mess of metals left behind after a meltdown. The company can’t just copy the drills that broke up the melted core of the Three Mile Island reactor, says Suzuki. “At Three Mile Island, [the core] remained in the pressure vessel,” he says. “In our case, it goes through the pressure vessel, so it melted stainless steel. So our fuel debris must be harder.” The melted fuel may also have a lavalike consistency, with a hard crust on top but softer materials inside. TEPCO is now working with computer models and is planning to make an actual batch of corium in a laboratory to study its properties.

When the core material is broken up and contained, it will be whisked away to some to-be-determined storage facility. Over the decades its radioactivity will gradually fade, along with the Japanese public’s memory of the accident. It’s a shame that those twisted blobs of corium are too dangerous to be displayed in a museum, where a placard could explain that we human beings are so clever, we’re capable of building machines we can’t control.

Depending on whom you ask, nuclear power stations like Fukushima Daiichi are exemplars of either humanity’s ingenuity or hubris. But, the museum placard might add, these metallic blobs, plucked from the heart of an industrial horror, prove something else—that we humans also have the grit and perseverance to clean up our mistakes.

This article originally appeared in print as “Fukushima’s Next 40 Years.”