How to Build a Mile-High Skyscraper

When cities can’t build out, they build up

Click image for a larger view.

In 1956, architect Frank Lloyd Wright, a noted proponent of small, squat buildings, unveiled a design for a mile-high skyscraper. Wright acknowledged that construction materials available at the time were inadequate for his vision. “But it’s certainly possible now,” says Joseph Colaco, president of CBM Engineers in Houston.

What do Colaco and his contemporaries have that Wright didn’t? Well, to begin with, much better concrete. The strongest concrete available in the 1950s could withstand compression on the order of 21 megapascals, placing the ceiling on all-concrete construction at roughly 20 stories. Some of today’s tall concrete structures, such as the 88-story (420-meter) Jin Mao Tower in Shanghai, are being built with concrete that has a compression strength greater than 130 MPa. Their walls and internal skeletons no longer have to be ever thicker to support the heftier loads—which cuts construction costs and frees up interior space.

“Additives like whisker-thin steel fibers are enhancing concrete’s strength and rigidity,” says John Fernandez, a professor at MIT’s interdisciplinary building-technology program. “We’re also seeing research into smart fibers and carbon nanotubes that, when added to concrete, will increase compression strength beyond 200 MPa.” Fernandez’s work on smart fibers is also contributing to advances in so-called high-performance concrete, which is strong but optimized for other characteristics such as fire and blast resistance, vibration damping, and durability.

Just as important are leaps in elevator technology. One recent advance is a destination-oriented elevator system from Schindler Management of Ebikon, Switzerland. The Miconic 10 system uses a traffic management algorithm that takes into account usage patterns at different times of day. It optimizes its pickups and drop-offs by grouping passengers according to the floors they select. This technique minimizes the number of stops and prevents overcrowding. In buildings such as the 1900-room New York Marriott Marquis hotel in Times Square, it has reduced transit times by 30 percent.

For Kone Corp., an Espoo, Finland–based elevator manufacturer, less is more. Its MonoSpace elevator, introduced in 1996, eliminated the big machine rooms at the base of elevator shafts by distributing their drive motors and cables around the shafts’ perimeters. Kone’s MaxiSpace elevator—featuring its pizza-box-size PowerDisc gearless electric hoisting machine—has made big, bulky counterweights unnecessary. Heikki Leppänen, Kone’s executive vice president, says new passenger cabins installed in existing hoistways can be 30 percent larger than the ones they replace.

Otis Elevator Co., of Farmington, Conn., is looking to leapfrog current elevator technology—literally—with a system called Odyssey that lets multiple elevator cars travel in the same shaft. Rick Barker, a principal at elevator consultancy Barker Mohandas, of Bristol, Conn., who spearheaded the Odyssey project when he was at Otis, explained that the elevator cabs sit in metal frames that are raised and lowered inside the hoistway. When a cab gets the signal to change lanes, “a small linear induction motor propels it along a platform, allowing it to roll out of the frame and onto another frame,” Barker says.

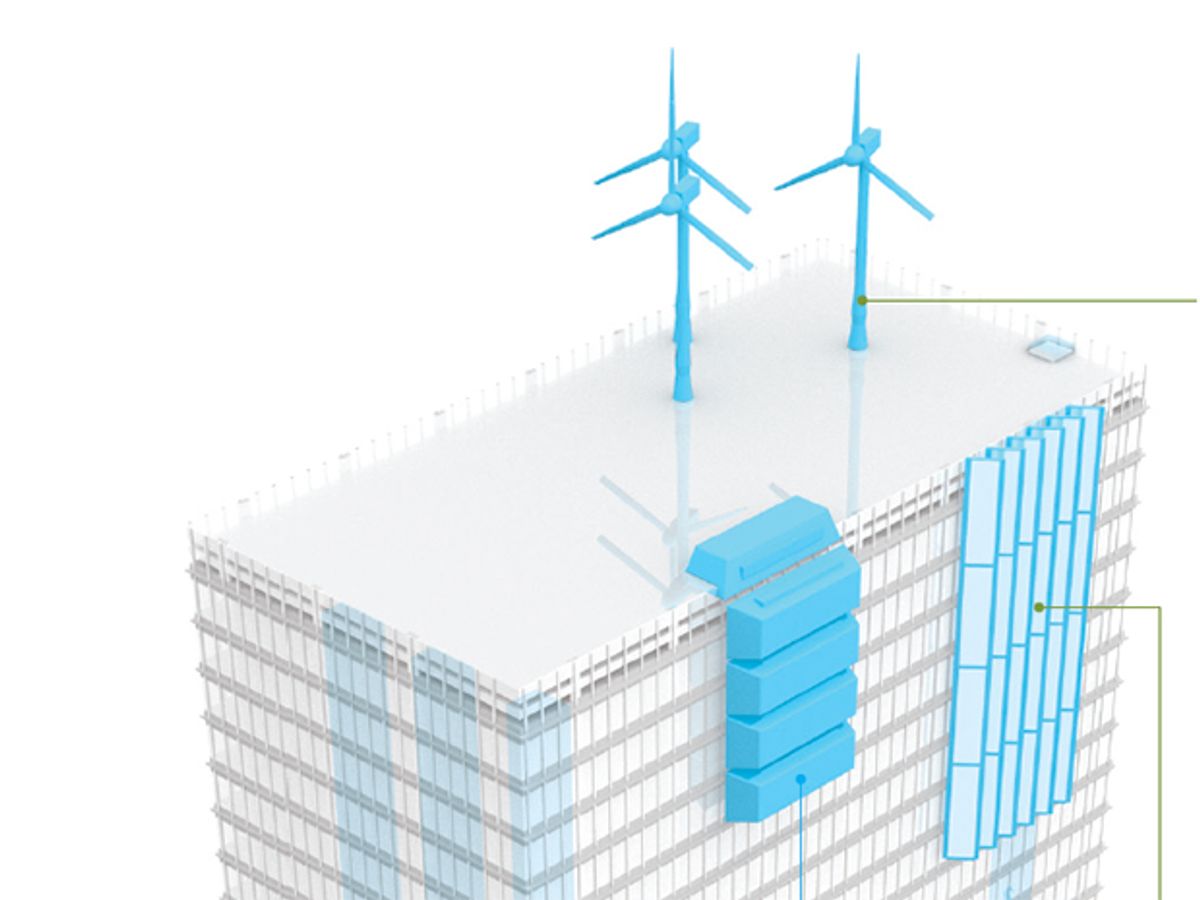

A mile-high skyscraper not only needs to be efficient in the way it transports people within, it also should be more energy efficient than existing structures, which together already consume about one-third of the world’s generating capacity. “With an integrated approach to the building envelope and the mechanical and electrical systems, we can significantly reduce energy consumption with little difference in construction costs,” says Spiro Pollalis, a professor at Harvard University’s Graduate School of Design. He envisions that photovoltaic panels along the length of the immense towers, along with strategically placed windmills and double-layer facades that act as giant heat sinks, will provide enough juice to power elevators and lights as well as heating, ventilation, and air conditioning systems.

“The ultimate aim is creating buildings with zero net energy use,” says Mir M. Ali, a professor of architecture at the University of Illinois at Urbana-Champaign and member of the international Council on Tall Buildings and Urban Habitat. Several skyscrapers under construction, including the Pearl River Tower in Guangzhou, China, are employing new technologies to avoid using any energy from the grid.

Critical as the aforementioned technologies are, none are worth discussing without a mention of those meant to help people on the upper floors of these massive towers escape in an emergency. In Asia, stringent fire codes mandate that buildings include innovations such as flame-, smoke-, chemical-, and gas-resistant refuge floors, where people can remain until firefighters douse a blaze.

Some Asian buildings are also equipped with pressurized staircases so people on lower floors aren’t overcome by smoke before they reach the lobby; with helipads for rooftop evacuation; and with emergency elevators with dedicated power supplies and rugged cabling that can withstand high temperatures for a long enough time to shuttle emergency responders to and from a fire.

One exotic proposed means of escape is a set of external elevators stored on a building’s roof. When the system is activated, five collapsible escape pods, each capable of carrying 30 people at a time, swing out over the edge of the roof, descend to the ground, and expand like accordions. Once the cabins are unfolded, the five-car unit ascends, picking up evacuees before returning to the ground. The system’s manufacturer, Escape Rescue Systems, of Tel Mond, Israel, says an up-down cycle can be repeated every 8 minutes.

Another proposal involves an electromagnet-studded shaft at each of a building’s corners. Each building occupant, having donned a vest lined with metal, can jump into a shaft for a controlled descent.

To see all of Spectrum’s special report on The Megacity, including online extras and audio and video exclusives, go to /moremegacity.