18 January 2012—A team at the University of Cambridge, led by IEEE Fellow Arokia Nathan, is working toward a simple goal: a mobile phone that requires charging less often. At the Materials Research Society's fall meeting in Boston, Arman Ahnood, a researcher on that team, told scientists that eventually, we might see a phone that never needs to be plugged in.

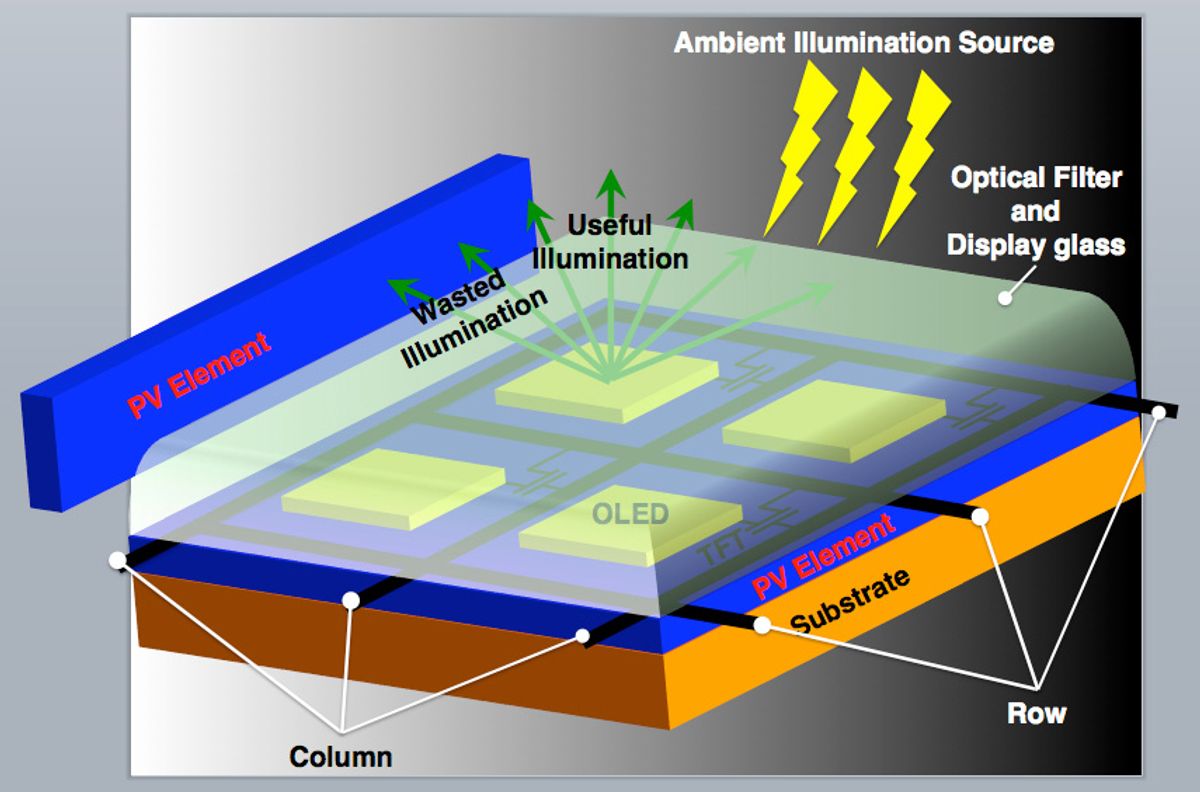

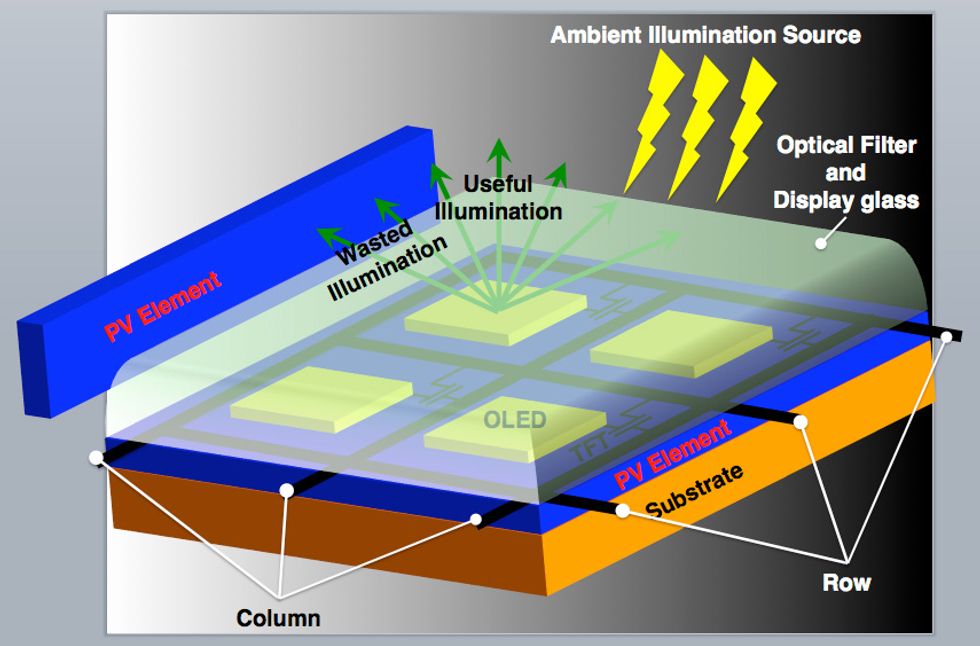

To extend the time between charges, Nathan's group built a prototype device that converts ambient light into electricity using an array of solar cells made of thin-film hydrogenated amorphous silicon that's designed to sit within the phone's screen. The photovoltaic (PV) cell takes advantage of the smartphone display’s large footprint. In a typical organic light-emitting diode (OLED) display, only about 36 percent of the light generated is projected out of the front of the screen, says Ahnood. Much of it escapes at the edges of the OLED, where it is useless. So Nathan and his collaborators at his Canadian firm IGNIS Innovation set out to harness this wasted light by putting thin-film PV cells around the display’s edges as well.

Making the device work required sidestepping another problem: fluctuations in the voltage provided by the solar cell, which could have damaged the phone’s battery. The researchers, who were based at University College London until recently, designed a thin-film transistor circuit to smooth out voltage spikes and extract electricity more efficiently.

And instead of charging the battery directly, which would have involved adding complex circuitry, they worked with the energy group at Cambridge's Centre for Advanced Photonics and Electronics to integrate a thin-film supercapacitor for intermediate energy storage. This combination of photovoltaics, transistors, and supercapacitor yielded a system with an average efficiency of 11 percent and peak efficiency of 18 percent. If the PV array converts 5 percent of ambient light to electricity, the energy-harvesting system can generate as much as 165 microwatts per square centimeter under the right lighting conditions. For a typical 3.7-inch smartphone screen, that equates to a maximum power output of 5 milliwatts, "which is quite useful power," says Ahnood, though that’s only a fraction of a smartphone’s power needs.

There are existing CMOS-based switch mode voltage regulators that offer higher efficiency, says Ahnood, but they aren’t compatible with the thin-film technology used in smartphone displays. Furthermore, the team’s thin-film devices can be fabricated at temperatures below 150 °C on lightweight plastic, making them much more attractive for use in mobile phones, where every gram and every penny is a big deal.

The cellular handset prototype is just one example of such small-scale wireless energy harvesting. Another plug-free power source might be magnetic resonance coupling via an induction coil. Alternating current is run through a coil of conductive material, generating an oscillating magnetic field. That field, in turn, generates a current in a coil embedded in, say, a phone or an MP3 player.

Jun Yu, a doctoral student of Nathan's, reported preliminary work along those lines at the MRS meeting. He told scientists that the team had designed a flat thin-film coil that could be used as a receiver in a display. But the team doesn’t foresee the coil producing enough power to run an entire computer. It should, however, be possible to scale down the magnetic coupling scheme for use in mobile devices.

It will take quite a bit more research to get from prototype to consumer product. For example, the team is exploring different circuit designs and materials with the aim of increasing the energy harvesting system’s efficiency. Other energy scavenging schemes, such as MEMS-based kinetic energy harvesting, could contribute to further improvements, says Nathan.

This story was corrected on 19 January. The affiliations of the research team was in error.

About the Author

Neil Savage writes about strange semiconductors and amazing optoelectronics from Lowell, Mass. In the January 2012 issue he reported on the invention of conductive and semiconducting cotton fibers.

Neil Savage is a freelance science and technology writer based in Lowell, Mass., and a frequent contributor to IEEE Spectrum. His topics of interest include photonics, physics, computing, materials science, and semiconductors. His most recent article, “Tiny Satellites Could Distribute Quantum Keys,” describes an experiment in which cryptographic keys were distributed from satellites released from the International Space Station. He serves on the steering committee of New England Science Writers.