Induction cook stoves are known for their efficiency, with over 90% of the energy used going directly into heating the food being prepared. That is a tremendous amount when compared to gas or electric stoves, which in contrast demonstrate a mere 50% efficiency rate. If an induction cook stove could provide chefs with better precision and speed than a traditional stove, while still retaining optimal efficiency, the resulting cooktop would be a substantial breakthrough in the cooking appliance industry.

It was the mission of Miele, a world leader in domestic appliances and commercial machines, to create just such an induction stove. Researchers at mieletec FH Bielefeld, a joint research laboratory between Miele & Cie. KG and the University of Applied Sciences Bielefeld, Germany, used simulation and the multiphysics approach to improve, verify, and optimize their induction stove designs.

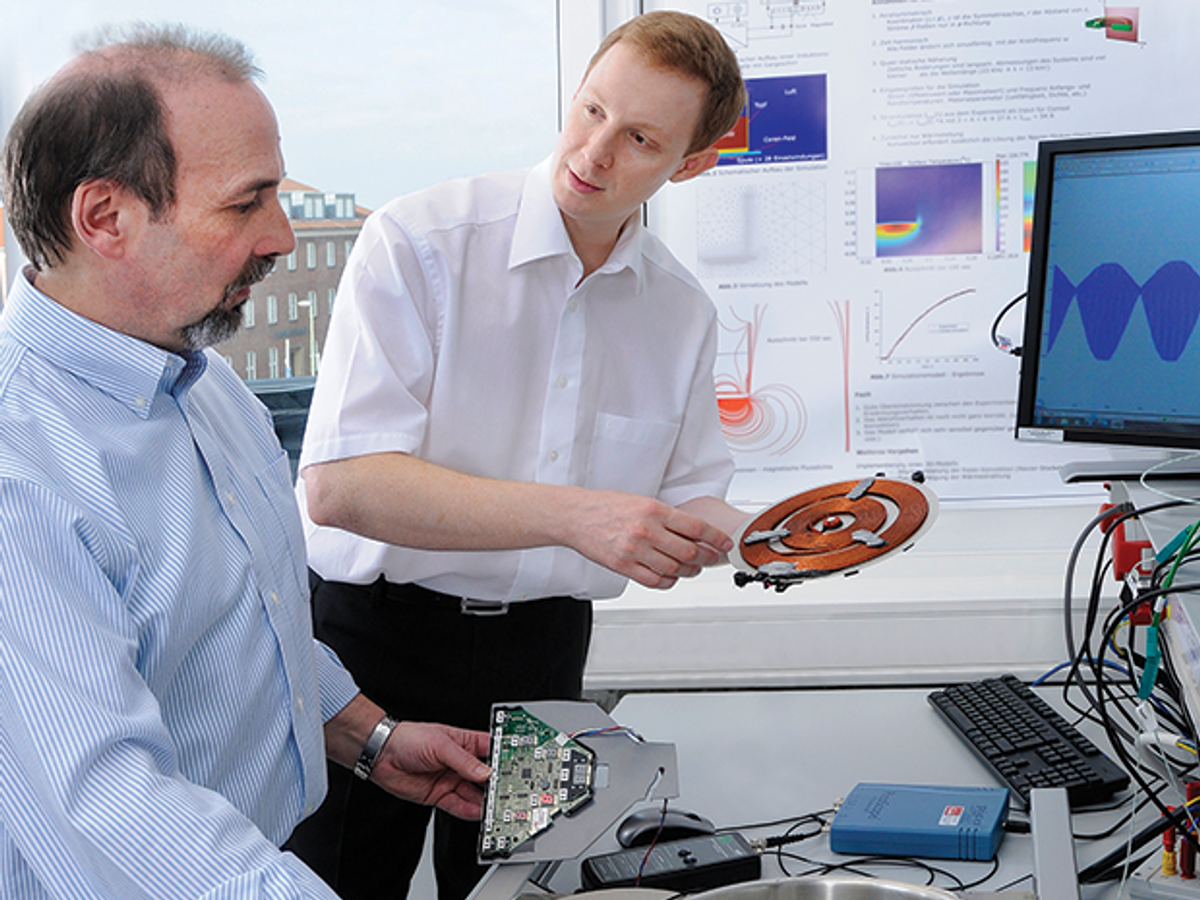

Using field-coupled simulation, Christian Schröder, co-founder and scientific director of mieletec, designed an optimized induction stove that lived up to Miele’s motto of “immer besser.”

Translated from German, this means “forever better” and it drives the company to create long-lasting, functional, and great designs. “We’re very happy with what mieletec has developed,” says Holger Ernst, co-founder and scientific director of mieletec and head of the Innovations Department at Miele. “Mieletec was able to create an induction stove that’s more precise than a gas stove, while still providing better energy efficiency.”

A WATCHED POT NEVER BOILS – UNLESS IT’S ON AN INDUCTION STOVE

A watched pot never boils. Whoever coined this phrase has probably never used an induction stove. Unlike gas or electric stoves, which can take ten to fifteen minutes to boil a pot of water, an induction stove can bring a cold pot of water to boiling in a matter of minutes. This is achieved using an entirely different heating technique than that of traditional stoves: induction heating.

An induction stove heats up a pot placed on the surface of the stove. While this sounds similar to the way in which a gas or electric stove functions, it’s actually an entirely different process. Induction stoves heat the metal of the pot, not the stovetop. “Instead of heating taking place on the stove,” describes Schröder, “heating actually takes place inside the pot itself, leaving the stove cool to the touch.” Traditional stoves heat the surface of the stove, which then heats the pot through conduction.

The working principle of an induction stove is based on the inductive heating effect. First, a pot is placed on copper coils located underneath the stovetop. When an alternating current (AC) is passed through the copper coils, it generates a magnetic field that induces currents inside the metal of the pot. These induced currents, called eddy currents, heat the pot by the Joule heating effect. The contents of the pot are then heated through conduction first and then convection.

Initially, induction stoves were designed using a trial and error process, where researchers relied on their experience for an initial estimation of what the frequency, coil size, and power output should be. The results were then altered until the best performance was seen, and this became the final design. However, this process can be very expensive and time consuming, and the engineer is left without enough information to know what is happening in the system, and whether the process has truly been optimized.

“Simulation allows you to extract data that you would never be able to get from an experiment,” says Schröder. “With simulation, you can get a better idea about what’s going on inside a coil or pot, so that you know what it is that you need to optimize.”

Using COMSOL Multiphysics® software and CAD geometries from Miele, Schröder and his team of researchers from mieletec were able to find the optimal set of conditions for the stove’s design. “Essentially, we were able to simulate the whole system, allowing us to improve upon the energy efficiency of the stove,” says Schröder. The accuracy of their simulations allowed them to optimize their results within COMSOL®, so that when the first prototypes were built, they already had a clear idea of how they would perform.

DESIGN CHALLENGES – WHEN POTS ARE SINGING AND MOVING ON THE STOVE

The magnetic field induced by the coils creates a few interesting design challenges. “One of the biggest issues we faced is the noise that the pots emit when eddy currents are flowing through them,” says Schröder. “The electrical current produces a high-pitched noise that is very difficult to get rid of. The only way to eliminate the noise is to adjust the frequency of the alternating current and geometry of the coil, so that the noise produced is at a higher pitch than what the human ear can pick up.”

For example, in Germany the current from a household outlet is standardized at 220 V and 50 Hz. Utilizing an AC/AC converter, the frequency of the current in the coil can be increased until the noise produced by the pot is no longer audible. “Using simulation, we found the recipe for current frequency and coil design that produced the least amount of noise possible,” comments Schröder. By increasing the frequency to 30 kHz, and optimizing the coil, mieletec built an induction stove that is almost silent to the human ear. Why almost silent? Because, even if the working frequency is not in the audible range, different noise generating phenomena, like magnetostriction, can still occur at lower, audible frequencies.

The induction heating process was simulated using COMSOL® in combination with the AC/DC Module and Heat Transfer Module. In order to obtain an accurate description of what happens in the stove and pot, heat transfer was solved simultaneously with electromagnetics and optimized to determine the best operating conditions. “At the moment, this is something that every manufacturer has to deal with,” Schröder continues, “however, in the future, we hope to create an induction stove that really is silent.”

Another challenge occurs because of the magnetic forces generated by the system. Since induction cookware is made of a paramagnetic metal, its interaction with the magnetic field results in an attraction force that can cause the pot to move around when placed on the stovetop. This occurs because the eddy currents in the pot generate a magnetic field that interacts with the one generated by the coils. If the magnetic forces do not cancel each other out, the resulting net force will cause the pot to move across the stove.

“We needed to know the size to make the coils, what shape, and what materials to use,” says Schröder, “It all boils down to material science.” Using simulation, Schröder and his team were able to gain an understanding of how the properties of different materials affect their design with respect to thermal and electromagnetic performances. This enabled them to create a coil design that ensured the pot would stay put, while still providing the right amount of power for cooking.

COMPARING SIMULATIONS WITH PROTOTYPES

When it came to testing their prototypes, mieletec was impressed with the results that they found. “It was amazing,” says Schröder. “We found that the results predicted by our simulations were in very good agreement with what the measurements on the prototypes displayed, which rarely happens with other software.”

Because their simulations accurately demonstrated how the prototypes would perform, mieletec was able to save a lot of development time and reduce the number of experiments needed to finalize their designs by 80%. In order to test that their induction stoves heat food homogenously, mieletec uses a pancake to assess heat distribution across the surface of the pan. “If the standard pancake comes out burnt in some places, and undercooked in others, then you know the stove isn’t heating effectively,” Schröder describes. “You want the pancake to be one smooth color and evenly cooked.”Stiftung Warentest (www.test.de), a trusted German authority on consumer goods, ranked Miele stoves as the best in energy efficiency and more importantly, able to prepare a delicious, nicely browned pancake.”

SIMULATION OF TRADITIONAL APPLIANCES

Mieletec is also working on additional kitchen appliances, such as convection ovens. In this application, a complete understanding of the materials and multiphysics interactions taking place were once again important when developing an optimized oven. In order to verify the optimized design, a test is performed in which a porous stone saturated with water is placed inside the oven. Over several days, the stone is passed through various heating cycles to evaluate the oven’s heating rate and energy efficiency.

“We had to work with a natural convection heat transfer simulation where porous media flow was also involved, a truly multiphysics application,” comments Schröder. “The simulation allowed us to measure the temperature of the stone at points in the experiment that were inaccessible to real sensors. Simulation allowed us to gain a better understanding of the design,” he continues. “A test that in practice lasts for a few days took only a few hours to achieve when simulated. This resulted in important saving of time and resources. Not to mention the fact that our conventional ovens achieved the highest energy efficiency rating.”

THE FUTURE OF DOMESTIC APPLIANCES

Thanks to simulation, mieletec is delivering designs from which consumers are already benefitting in terms of improved energy efficiency and a better cooking experience. The next step is to reach a deeper understanding of the whole induction heating system by including complex multiphysics effects like magnetostriction and aging of materials. Additionally, mieletec is working on the next generation of induction stoves, known as multicoil induction stoves, which will allow a consumer to place their pots and pans anywhere on the stovetop, instead of inside predefined boundaries. The stove will automatically be able to sense the location of the pot, and adjust accordingly to produce optimal cooking conditions by turning on a certain set of coils.

These hot new designs in cooking appliances are revolutionizing the cooking industry, making safer and more energy efficient stoves available for at-home and professional chefs. “We’re looking forward to seeing mieletec continue to deliver cutting-edge technologies using COMSOL® to facilitate the design process,” concludes Ernst.