In the age of flash memory and DNA-based data storage, magnetic tape sounds like an anachronism. But the workhorse storage technology is racing along. Scientists at IBM Research say they can now store 201 gigabits per square inch on a special “sputtered” tape made by Sony Storage Media Solutions.

The palm-size cartridge, into which IBM scientists squeezed a kilometer-long ribbon of tape, could hold 330 terabytes of data, or roughly 330 million books’ worth. By comparison, the largest solid-state drive, made by Seagate, is twice as big and can store 60 TB, while the largest hard disk can store only 12 TB. IBM’s best commercial tape cartridge, which began shipping this year, holds 15 TB.

IBM’s first tape drive, introduced in 1952, had an areal density of 1,400 bits per square inch and a capacity of approximately 2.3 megabytes.

IBM sees a growing business opportunity in tape storage, particularly for storing data in the cloud, which is called cold storage. Hard disks are reaching the end of their capacity scaling. And though flash might be much zippier, tape is by far the cheapest and most energy-efficient medium for storing large amounts of data you don’t need to access much. Think backups, archives, and recovery, says IBM Research scientist Mark Lantz. “I’m not aware of anything commercial or on the time horizon of the next few years that’s at all competitive with tape,” he says. “Tape has huge potential to keep scaling areal density.”

To store data on tape, an electromagnet called a write transducer magnetizes tiny regions (small crystals called grains) of the tape so that the magnetization field of each region points left or right, to encode bits 1 or 0. Heretofore, IBM has increased tape drive density by shrinking those magnetic grains, as well as the read/write transducers and the distance between the transducers and the tape. “The marginal costs of manufacturing remain about the same, so we reduce cost per gigabyte,” Lantz says.

The staggering new leap in density, however, required the IBM-Sony team to bring together several novel technologies. Here are three key advances that led to the prototype tape system reported in the IEEE Transactions on Magnetics in July.

-

New Tape Schematics

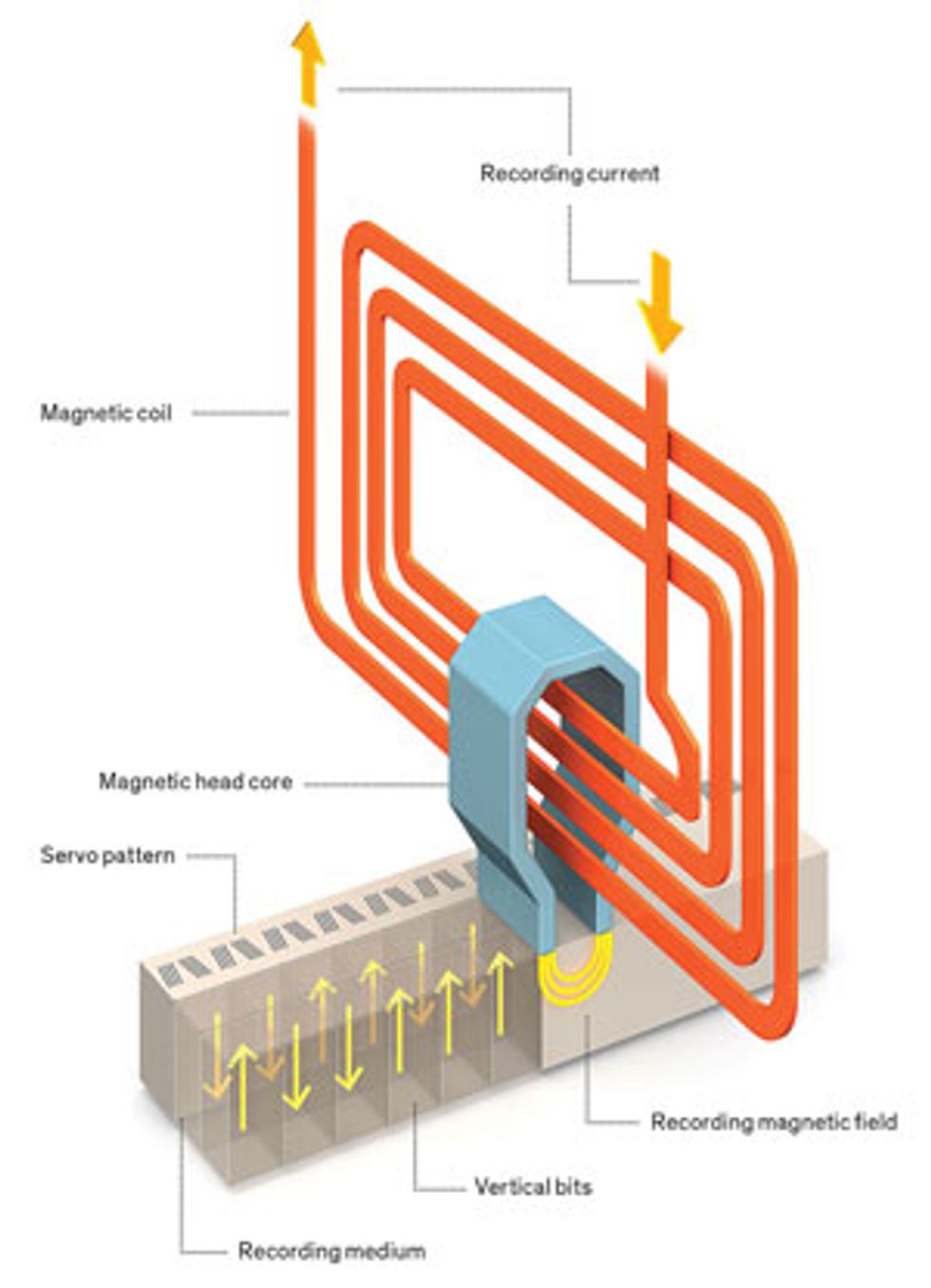

The surface of conventional tape is painted with a magnetic material. Sony instead used a “sputtering” method to coat the tape with a multilayer magnetic metal film. The sputtered film is thinner and has narrower grains, with magnetization that points up or down relative to the surface. This allows more bits in the same tape area.

Think of each bit as a rectangular magnetic region. On IBM’s latest commercially available tape, each bit measures 1,347 by 50 nanometers. (Hard disk bits are 47 by 13 nm.) In the new demo system, the researchers shrunk the data bits to 103 by 31 nm. The drastically narrower bits allow more than 20 times as many data tracks to fit in the same width of tape.

To accommodate such tiny data elements, the IBM team decreased the width of the tape reader to 48 nm and added a thin layer of a highly magnetized material inside the writer, yielding a stronger, sharper magnetic field. Sony also added an ultrathin lubricant layer on the tape surface because the thinner tape comes in closer contact with the read/write heads, causing more friction.

Illustration: Emily Cooper Mo’ Better Bits: Stacking the bits vertically and refining the servo pattern that helps the read/write head maintain precise positioning let IBM Research scientists pack in more data and access it with improved accuracy. More Precise Servo Control

Very much like magnetic disks, every tape has long, continuous servo tracks running down its length. These special magnetization patterns, which look like tire tracks, are recorded on the tape during the manufacturing process. Servo tracks help read/write heads maintain precise positioning relative to the tape.

The IBM team made the servo pattern shorter, narrower, and more angled in order to match the smaller magnetic grains of the tape media. They also equipped the system with two new signal-processing algorithms. One compares the signal from the servo pattern with a reference pattern to more accurately measure position. The other measures the difference between the desired track position and the actual position of the read/write head, and then controls an actuator to fix that error.

Together, these advances allow the read/write head to follow a data track to within 6.5-nm accuracy. This happens even as the tape flies by at speeds as high as 4 meters per second (a feat akin to flying an airplane precisely along a yellow line in the road).

-

Advanced Noise Detection and Error Correction

As the bits get smaller, reading errors go up. “If we squeeze bits closer, the magnetic fields of neighboring bits start to interfere with the ones we’re trying to read,” Lantz says. So the difference between a lower-value 0 signal and a higher-value 1 might be harder to make out. To make up for this, magnetic storage technologies use algorithms that, instead of reading a single bit, take into account signals from a series of bits and decide on the most likely pattern of data that would create the signal. The IBM researchers came up with a new and improved maximum-likelihood sequence-detection algorithm.

They also improved upon the storage technology’s error-correction coding, which is used to slash bit-reading error rates. In the new system, the raw data goes through two decoders. The first looks for errors along rows, while the stronger second one checks columns. The data is run through these decoders twice.

Prachi Patel is a freelance journalist based in Pittsburgh. She writes about energy, biotechnology, materials science, nanotechnology, and computing.