Since bipedal robots took their first steps, the majority has been designed with the same basic joint/actuator configuration in their legs. This design, based on a simplified human leg, uses just six motors (three for the hip, one for the knee, and two for the ankle), and though it proved successful, it has also shown several limitations over the last 25 years. Now researchers at the Humanoid Robotics Institute at Waseda University (the birthplace of the first real humanoid robots) have set out to reinvent the wheel, er, the leg, by developing an entirely new shank that more closely replicates human walking.

The researchers, led by Professor Atsuo Takanishi, presented their groundbreaking work at the IEEE International Conference on Robotics and Automation (ICRA), early this month, in Germany. To design and test their new calf "muscles," the group started by taking a closer look at the legs of one of their robots: WABIAN-2R (WAseda BIpedal humANoid - No. 2 Refined) has been regarded as one of the world's most sophisticated humanoid robots since it was unveiled in 2006. It stands 148 cm (4 feet 10 inches) tall, weighs 64 kg (141 pounds), and, with its 41 degrees of freedom, can perform very human-like movements. What sets it apart from many other bipeds is its flexible pelvis, which gives it the ability to walk with stretched knees (unlike Honda's ASIMO, among others).

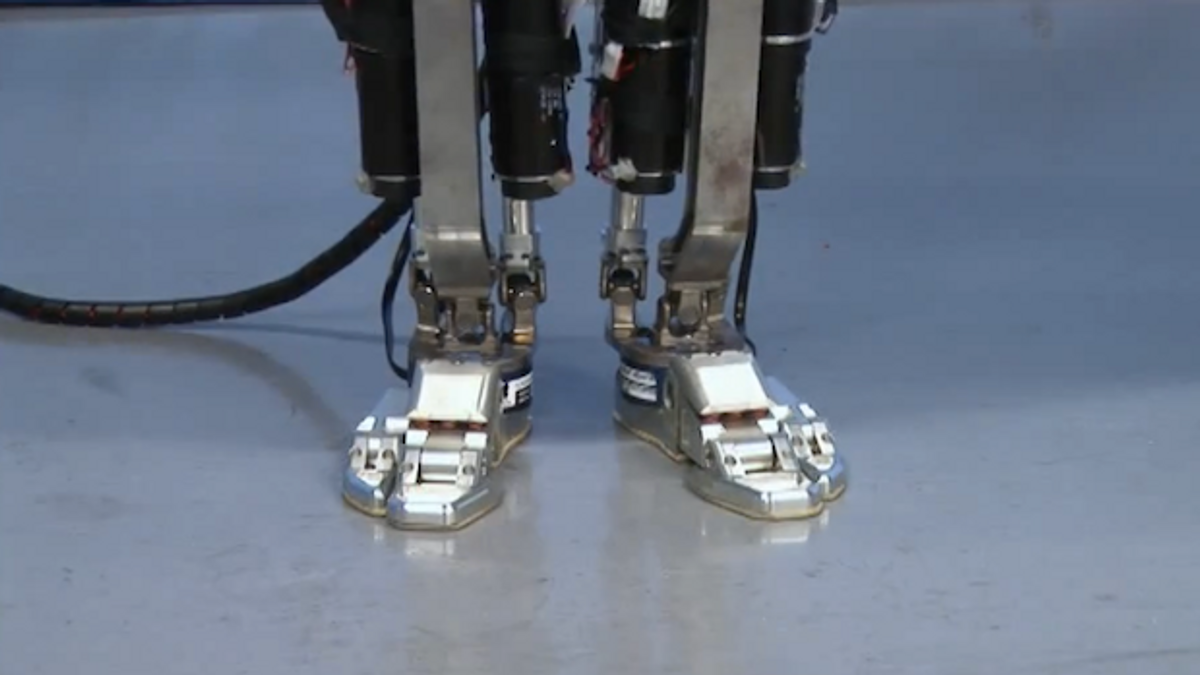

Most biped robots walk with flat feet that land parallel to the ground but WABIAN-2R's feet, with curving arch and flexible toes, lands heel-first and lifts off at its toes. That's progress, but a few vexing inconsistencies remain: humans walk with their feet roughly 90 mm (3.5 inches) apart, a distance doubled by the robot due to its large ankle motors. When walking, the robot's center of mass had a lateral movement of 50 mm (compared to just 30 mm for a human). And it couldn't mimic a person's foot rotation (approximately 12 degrees) due to a missing yaw joint in its ankle; a problem it and other biped robots inherited through the old joint configuration.

So with those limitations in sight, the Waseda researchers started working on their new leg. The missing foot rotation could come from the yaw axis in the hip, but that would also rotate the knee and just introduce its own set of problems. Instead, the researchers decided they would have to add a yaw joint somewhere below the knee, while at the same time shrinking the lower leg's overall size to shorten the step width between the feet. They began by looking at the average size and movement range found in humans, and analyzed motion-capture data to determine the optimal performance requirements of their new ankle.

In designing the prototype, the yaw rotation would be provided by a motor located at the top of the shin, just under the knee. The two motors normally situated in the ankle for pitch and roll were ditched in favor of a linear parallel link mechanism, which trimmed precious millimeters off the lower leg's circumference. Here is where they ran into their first major problem: there was no commercially available ball joint strong enough to withstand the compressive loads it would need to support. Their solution was to design one from scratch with the help of Japanese company Hephaist Seiko. (The project was supported in part by the Humanoid Robotics Institute, RoboSoM project, and Japan's MEXT.)

But the shank prototype's universal joints were causing problems and needed to be redesigned. Minor tweaks to the universal joints, and material changes, resulted in vastly improved stiffness and increased movable range. These and other refinements led to an entirely new system (pictured above, right). The researchers installed the new shank in their humanoid robot, which is now called WABIAN-2RIII.

This time, the robot worked marvelously. In experiments where it walked in place (see video above), not only was it able to match the human step time of 0.6 seconds, it also matched the required 12 degree foot rotation and 90 mm step width (see image below, right, showing the new design, and the one on the left, with the original robot, which had zero-degree foot rotation and 180 mm step width). The researchers have also successfully reduced its center of mass lateral movement from 50 mm down to 34 mm (just 4 mm shy of an actual human).

Next, the team plans on experimenting with forward walking, and reckon they can make adjustments to their existing walking pattern to achieve more realistic, human-like walking.

The researchers, T. Otani, A. Iizuka, D. Takamoto, H. Motohashi, T. Kishi, P. Kryczka, N. Endo, L. Jamone, K. Hashimoto, T. Takashima, H.O. Lim, and A. Takanishi, report their results in the paper, "New Shank Mechanism for Humanoid Robot Mimicking Human-like Walking in Horizontal and Frontal Plane," presented at ICRA in Germany.