Robots Will Pave the Way to Mars

Technologies that exploit space resources will finally open up the solar system to human exploration

The first robot capable of building anything including a replica of itself, might cost a fortune to develop; the billionth copy would be as cheap as dirt. Send some of them into space and they could build new armies out of planetary rubble and dust, then go on to construct enough spaceships and refueling stations to carry the human race to other planets and, eventually, other stars.

That’s the scenario laid out some 35 years ago by a team of academics and NASA engineers meeting at the University of Santa Clara, in California. They envisioned robotic factories that would cover the moon and exploit the asteroid belt, extracting the resources needed to build more and better versions of themselves and also vast orbiting telescopes, space colonies, and other structures too big to launch from Earth. Over time, the researchers wrote, these bots could “produce an ever-widening habitat for man throughout the Solar System” and beyond it. The approach could become so successful, they warned, that we might have to worry about robotic population control.

None of that, of course, has come to pass. Except for solar power, everything we use in space comes from Earth. But signs of change might be on the horizon. The next few years will see the launch of the first equipment that can make water out of lunar soil and print entirely new structures in microgravity. These are the seeds of the two basic technological capabilities—resource extraction and structure fabrication—that will be needed to build things in space that don’t have to be launched from Earth.If these technologies mature, experts say, they could transform the space environment. In 50 years, commercial outfits may tow drinking water, extracted from icy asteroids, to thirsty astronauts in Earth orbit. Vast solar arrays, built on trusses made from cemented lunar soil, could beam energy to Earth’s surface. Radio antennas hundreds of meters wide could scrutinize the black hole at the center of the galaxy. And humans could finally be able to gather the resources they need for round-trip journeys to the surface of Mars.

Nothing about this future is guaranteed. Space plans shift with the political winds, and there is perennial debate over why we should go to space and what the balance of human and robotic exploration should be.

Seeking Out New Life

Our hunt for other life in the solar system has focused mostly on Mars. But other spots may also be habitable—at least by small microbes. In the next 50 years, it should be possible to reach them all and at least perform a first pass at assessing whether they harbor life.

Among the best candidates is Saturn’s moon Enceladus. It is now thought to contain a liquid ocean beneath its south pole, and it jettisons not just water but water rich with organic molecules into space. “It’s the only place in the solar system where we know that the major requirements for habitability are met and samples are easy to get,” says Chris McKay, an astrobiologist at NASA’s Ames Research Center, in Moffett Field, Calif.

A close second is Jupiter’s moon Europa, which is also thought to boast a liquid ocean beneath the surface. For years, this ocean was believed to be impenetrable, wrapped in an icy crust that could be dozens of kilometers thick. Engineers at Honeybee Robotics’ lab in Pasadena, Calif., are working on a tethered drill that could cut through that ice and still be lightweight enough to launch to Jupiter. But the drill may not be needed—at least on a first pass of the moon; last year, Europa was discovered to have watery plumes of its own.

And then there is Saturn’s moon Titan, with lakes full of liquid methane and ethane that might boast more exotic forms of life. Although the European Space Agency’s Huygens probe landed on Titan in 2005, these liquid environments remain unexplored. —R.C.

But robotic systems capable of construction and resource utilization could address the single biggest obstacle to the exploration of space: the expense.

“The technical facts of life in space are that it’s hard to get there, it’s hard to stay there, and it costs money to do it repeatedly,” says Paul Spudis, a scientist at the Lunar and Planetary Institute, in Houston. Rocket companies still charge roughly US $10 000 to $20 000 to loft every kilogram of stuff into low Earth orbit. Many are now eying newcomer SpaceX, which is promising to deliver lower prices with a new heavy-lift rocket. But driving down the costs significantly would require either many more launches, to achieve economies of scale, or an improvement on chemical rocketry. Neither is on the horizon, Spudis says, and that leaves us with one alternative. To get beyond low Earth orbit and the half dozen lunar landings already under our belts, we must find a way to live off the land.

The moon alone has plenty of raw material to go around. The loose soil can be sintered or glued together to make crude structures. Silicon, which makes up roughly 20 percent of the soil by weight, can be extracted and purified to create rudimentary solar cells. And, crucially, there seems to be water, a multipurpose resource that can be purified for drinking, poured into containers to make radiation shielding, and split into hydrogen and oxygen to form rocket fuel. The ice locked up in the moon’s north pole alone, Spudis says, is “enough to launch the equivalent of a space shuttle from the surface of the moon every day for 2200 years.”

We could do far more in space if we make what we need out of what we can find, says Mason Peck, a professor of mechanical and aerospace engineering at Cornell and former NASA chief technologist. “I like to say that all the mass we’re ever going to need to explore in space is already in orbit. It’s just in the wrong shape.”

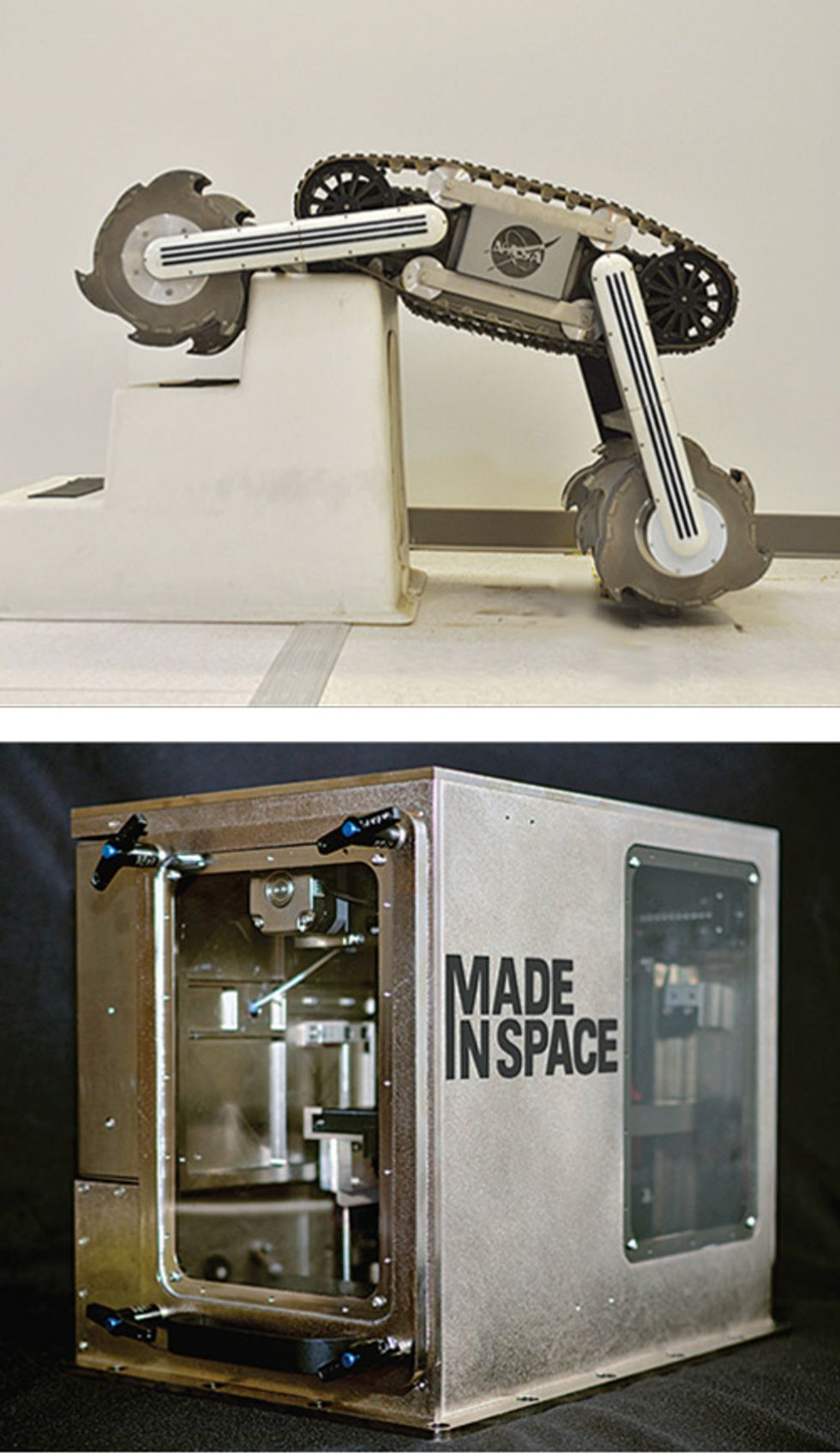

Getting mass into the right shape is one of the goals of NASA’s Swamp Works. The laboratory, based at Kennedy Space Center, in Merritt Island, Fla., occupies a building where Apollo astronauts once trained; it now boasts perhaps the world’s largest collection of “lunar simulant”—artificial moon dirt. Some 120 tons of the stuff, detritus of a mining operation in Black Point, Ariz., sit in a glass-walled room. Here physicist Philip Metzger and his colleagues test the Regolith Advanced Surface Systems Operations Robot, or RASSOR, a rugged-looking industrial rover the size of a bumper car. RASSOR is more or less rectangular when stretched out. At each end, a pair of pivoting arms holds a long, hollow, rotating drum, studded with shovel-shaped openings. For digging leverage against the moon’s reduced gravity, these drums are rotated in opposite directions, collecting lunar soil as they spin. When full, the robot can drive to a processing station, fold up so as to place a drum above a collection spot, and rotate the drum in reverse to empty it.

Metzger expects that such technology could kick off a lunar industry that slowly bootstraps its way up in sophistication. Crude robotic factories, remotely operated by humans, would be used to build slightly more capable systems, which would make even more capable ones, and so on. Metzger and his colleagues have modeled how this might work, and they reckon that as little as 12 metric tons of equipment sent to the moon would be enough to jump-start the evolution of a self-sustaining robotic industry. In time, he says, this approach could lead to the robotic colonization, or “robolonization,” of the solar system.

This might sound outlandish, Metzger says, but most of what we build in space doesn’t have to be as sophisticated as what we send from Earth. Because launch mass isn’t a concern, he says, “we can build a giant, clunky robot out of iron instead of a small, lightweight one out of titanium.” Truly advanced components, such as computer chips, could be shipped in batches and slotted into robots until they too could be manufactured in space. One of the key challenges, Metzger says, will be improving reliability. Lunar dust has a habit of getting into everything, and regular human repair missions can’t be expected.

RASSOR is not slated for launch, but another NASA team is preparing a flight-ready version of what could become the first equipment to extract and make resources on the moon: the Regolith and Environment Science and Oxygen and Lunar Volatile Extraction (RESOLVE) experiment. RESOLVE is currently an experiment without a spacecraft, but NASA hopes to find a way to launch it on a rover as early as 2019. It is designed to hunt for hydrogen, which could possibly point the way to water ice. While in operation, RESOLVE will also attempt to make water, by heating lunar soil to 900 °C to release oxygen and combining it with hydrogen carried in from Earth.

For any harnessing of space resources to work, many experts say, the government will need to play a big role, creating infrastructure much as it might build a mail system or a network of highways or any other backbone of commerce. But that hasn’t stopped private companies from wading in. One of these is Planetary Resources, which is setting its sights on trips to near-Earth objects beginning in the early 2020s. On its first forays the company will search not for platinum and other pricey metals—the typical quarry of space mining outfits—but for water. The firm expects to extract it from some kinds of asteroids simply by using heat from concentrated sunlight, says Chris Lewicki, the company’s president and chief engineer. “Our focus isn’t necessarily on inventing new technology,” he says. “It’s on doing with a small team what once used to take the government.”

Gathering raw materials is only the beginning. To build up infrastructure, we must also develop ways to fabricate and manipulate structures in space.

The U.S. Defense Advanced Research Projects Agency has been making headlines with the Phoenix project, which would use advanced robotics and modular components to construct spacecraft in orbit. Among other uses, this combination could extract the antenna from a defunct satellite and build a new one around it.

A company called Tethers Unlimited, based in Bothell, Wash., hopes to fabricate structures from scratch, on even larger scales. Its project, called SpiderFab, aims to use robotic arms to build up and maneuver across 3-D–printed structures while floating free in orbit. The goal is to create objects that are too big to be folded into the top of a rocket. “What we’re trying to do is figure out how to make it not ridiculous to talk about antennas that are hundreds or thousands of meters in diameter,” says CEO Robert Hoyt. One of the biggest challenges Tethers is tackling now is how best to manage the thermal environment, Hoyt says. The temperature can vary by hundreds of degrees in orbit, and large temperature gradients could prevent structures from properly cooling and hardening, causing wild deformations.

The first 3-D printer to go into space won’t suffer such problems. Built by Made in Space, a start-up based in Moffett Field, Calif., and set to be delivered to the International Space Station later this year, it will be safely ensconced in a climate-controlled glove box. The printer makes objects out of heated polymer filament, just as many terrestrial 3-D printers do, but it has been altered to work in microgravity. The team logged hundreds of hours on parabolic flights to perfect the technology, says lead engineer Michael Snyder, but he won’t disclose what sets it apart from typical 3-D printers. “That’s our special sauce,” he says. The company plans to send an improved version of the printer to the station in 2015 and rent time on it to anyone who might want to print in space.

Both SpiderFab and Made in Space printers would require carrying material up from Earth to be used as the raw material for construction. Printing structures using material gathered elsewhere is still on the horizon. Although the European Space Agency, NASA, and others have looked into building very crude structures—mostly human habitats and landing pads—out of lunar soil, at present there are no plans to try out these ideas in space.

Still, many say the basic ingredients needed to build a true space infrastructure are more or less ready. Now we must find a way to combine them. Only then will our machines be able to prepare the way for our own forays to the moon, the planets, and the stars, turning us at last into a truly spacefaring species.

What Could Possibly Go Wrong?

No Buck Rogers, No Bucks

Business as usual could spell the end of public support for space exploration

Illustration: MCKIBILLO

All hopes for space will come to nothing if the future resembles the present, with tight budgets and constantly changing plans. “I’ve been in the space business for 35 years,” says Paul Spudis, a scientist at the Lunar and Planetary Institute, in Houston. “I’ve never seen such a screwed-up mess as we now have.”

NASA’s current plans call for sending humans to Mars in the 2030s, but any such trip is at least 60 years away, argues Ralph McNutt, a physicist at Johns Hopkins University’s Applied Physics Laboratory, in Laurel, Md. “The price tags have come out to be so big that they’re just not palatable.” But Mars is easy for politicians to support, he says: They can advocate for the long-term goal without diverting enough funds today to make it happen.

Dithering could slowly eat away at public support. “I think the worst case would be if we continue only with these occasional piecemeal, individual missions that are kind of designed to be self-sustaining, like Conestoga wagons full of all the supplies you’ll ever need,” says Mason Peck, a professor of mechanical and aerospace engineering at Cornell and former chief technologist at NASA. “I think that will limit the amount of science that can be done and the amount of human exploration that we can do,” Peck adds. “If that persists, I think eventually people will lose patience, and there will be less and less public support for space exploration and science generally. Then we’ll never be able to get off the planet in a permanent way.”

But even if the government does push aggressively to build space infrastructure, the effort could still falter. A “killer app” that would vastly change the economic equation and make space development profitable still hasn’t been found. Scott Pace, director of the Space Policy Institute at George Washington University, in Washington, D.C., phrases the problem like a riddle: “What’s the question,” he asks, “for which space is the answer?”

There are also practical hurdles, such as the legality of claiming asteroids and lunar resources, says Henry Hertzfeld, a professor of space policy and international affairs at George Washington University. “Who has the rights? Do we have to divide them up, and if so, how? These issues would have to be addressed,” Hertzfeld says.

And if we somehow succeed in all our efforts, there could be side effects. For instance, we might spoil pristine environments of historical or scientific significance. Picking the path forward for space won’t be easy, but if we don’t carefully consider it, the choice could be made for us. —R.C.

A version of this article originally appeared in print as “Fewer Launches, More Space.”