This article is part of our exclusive IEEE Journal Watch series in partnership with IEEE Xplore.

Diesel and steam-powered trains have been transporting passengers and cargo around the world for more than 200 years—all the while releasing greenhouse gas emissions into the atmosphere. In the hopes of a greener future, many countries and companies are eyeing more renewable sources of locomotion. The Pittsburgh-based company Wabtec recently unveiled a battery-electric hybrid train that they say can reduce emissions "by double digits per train." More ambitiously, some are developing hydrogen-powered trains, which rather than emitting greenhouse gases, only produce water vapor and droplets.

The technology has the potential to help countries meet greenhouse gas reduction targets and slow the progression of climate change. But, producing electricity from hydrogen comes with its own challenges. For example, the fuel cells require additional heavy converters to manage their wide voltage range. The weight of these bulky converters ultimately reduces the range of the train.

In a recent advancement, researchers in the UK have designed a new converter that is substantially lighter and more compact than state-of-the art hydrogen cell converters. They describe the new design in study published August 25 in IEEE Transactions on Industrial Electronics.

Pietro Tricoli, a professor at the University of Birmingham, was involved in the study. He notes that lighter converters are needed to help maximize the range that hydrogen powered trains can travel. Therefore his team developed the newer, lighter converter, which they describe in their paper as "ground-breaking."

It uses semiconductor devices to draw energy in a controlled way from the fuel cells and deliver it to the train's motors. "Our converter directly manages any voltage variations in the fuel cells, without affecting the motor currents. A conventional system would require two separate converters to achieve this," explains Tricoli. With the power converted to AC, the motors of a train can benefit from regenerative braking, whereby energy is harvested and recycled when the train is decelerating.

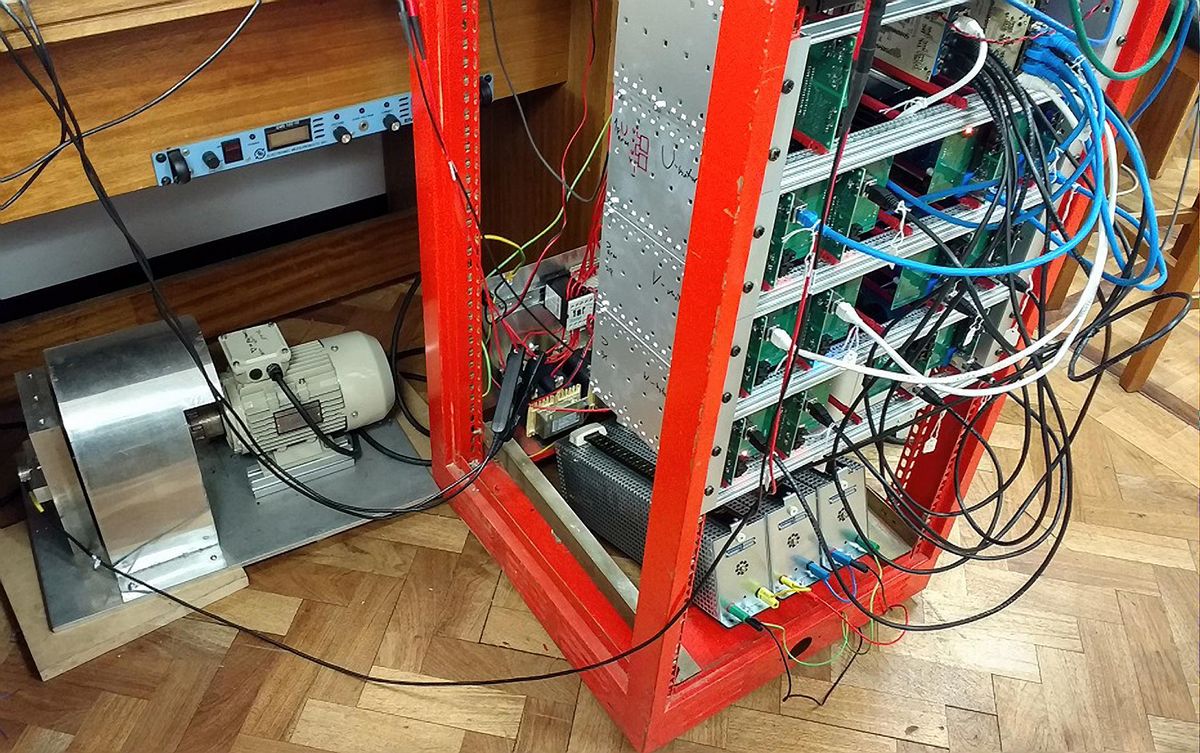

The researchers first tested their design through simulations, and then developed validated it through a small-scale laboratory prototype representing the traction system of a train. The results confirm that the new converter can facilitate desirable speeds and accelerations, as well as achieve regenerative braking.

"The main strength of the converter is the reduction of volume and weight comparted to the state of the art [converters for hydrogen fuel cells]," explains Tricoli. The main drawback, he says, is that the new converter design requires more semiconductor devices, as well as more complex circuitry and monitoring systems.

Tricoli says there's still plenty of work ahead optimizing the system, ultimately, toward a full-scale prototype. "The current plan is to engage with train manufacturers and manufacturers of traction equipment to build a second [prototype] for a hydrogen train," he says.

This past spring marked an exciting milestone when, upon the completion of a 538-day trial period, two hydrogen-powered trains successfully transported passengers across 180,000 kilometers in Germany—while emitting zero vehicle emissions.

As more advancements in hydrogen technology such as the above are made, more increasingly efficient hydrogen-powered trains become possible. All aboard!

Michelle Hampson is a freelance writer based in Halifax. She frequently contributes to Spectrum's Journal Watch coverage, which highlights newsworthy studies published in IEEE journals.