When Singapore high school students Marion Pang Wan Rion, Joy Ang Jing Zhi, and Sonia Arumuganainar decided they wanted to experiment with the “next big thing” in electronics, they chose graphene-based supercapacitors. The three wanted to come up with a design for a supercapacitor that would be lighter and more flexible than current ones, like those used to collect energy from regenerative braking in electric cars.

Their approach—and one that earned them a place among 16 finalist teams in Google’s international science fair this year—was to develop a graphene paint that would adhere to any surface and still be stable and flexible. Paint frees the supercapacitor from the bulk of current models that must somehow fit into a car body. This supercapacitor can just be painted on the car body, explained 18-year-old Zhi.

In their early attempts, the graphene flaked off, Zhi told me during Google’s showcase for the international finalists, held Tuesday. Then, she said, they found the perfect additive—basic white school glue.

In the future, says Zhi, these flexible supercapacitors could be part of the band of a smart watch or used for biological implants.

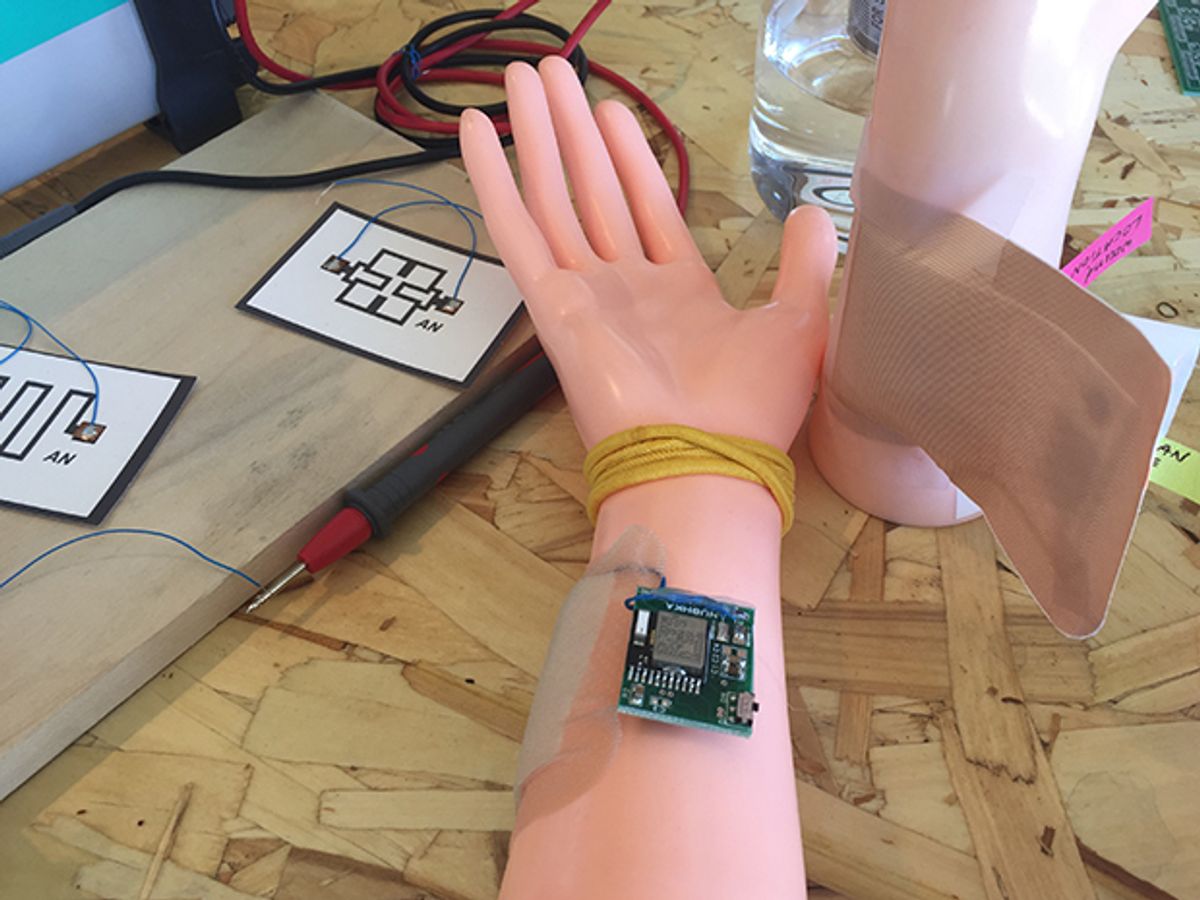

Meanwhile, Anushka Naiknaware from Portland, Ore. was also looking to build light and flexible electronics. The 13-year-old wanted to create a sensor to monitor the moisture around a wound while avoiding bandage changes, which slow healing. She filled an inkjet cartridge with conductive ink to print her sensors on bandages, and developed a wearable monitor, intended to strap on a patient’s wrist, to collect data from the sensors. Naiknaware was awarded the Lego Education Builder Award, one of two prizes given for the best solutions to difficult engineering challenges at the event.

More on these projects, as well as the grand prize and other winners, here.

Tekla S. Perry is a senior editor at IEEE Spectrum. Based in Palo Alto, Calif., she's been covering the people, companies, and technology that make Silicon Valley a special place for more than 40 years. An IEEE member, she holds a bachelor's degree in journalism from Michigan State University.