While the exact cause of the recent fires experienced with Samsung’s Galaxy Note 7 smartphones have not yet been precisely determined, it appears that these incidents are in some way related to the batteries.

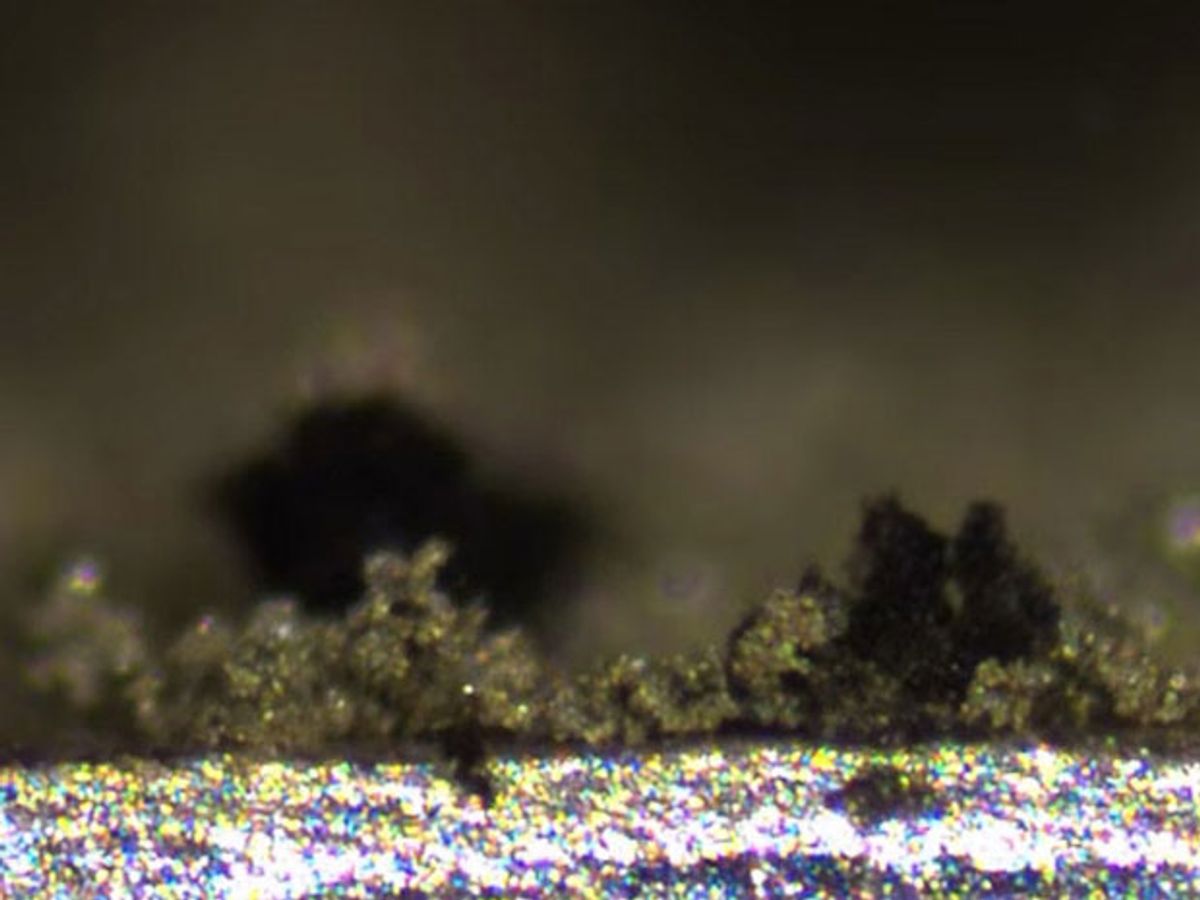

One known problem for both the lithium-ion (Li-ion) batteries used in today’s mobile phones as well as next-generation lithium metal batteries is that they are susceptible to the growth of finger-like deposits of lithium called dendrites inside the battery. These dendrites grow so long that they pierce the barrier between the two sides of the battery and cause a short circuit, possibly leading to a fire.

Now researchers at the University of Michigan—inspired by the potential of next-generation lithium metal batteries to store 10 times more charge than conventional Li-ion batteries—have peered into lithium metal batteries to observe the growth of dendrites. They leveraged a novel microscopy tool that enables them to watch how the lithium changes inside the battery during cycling to create conditions conducive to dendrite growth.

In research described in the journal ACS Central Science, the scientists were looking for a way to observe the extreme reactivity of liquid electrolytes and Li metal inside the battery.

While other research teams have used optical microscopy techniques, such as transmission electron microscopy (TEM), to observe these reactions inside the battery during operation, the Michigan researchers are the first to link the time evolving changes to the lithium with the corresponding changes in voltage.

Researchers now have a better understanding of how the reactions between the electrolyte and the metal electrodes affect the lithium morphology and electrochemistry during cycling.

To make these observations, the researchers turned to a microscopy technique known as operando high-resolution video capture and combined it with a numerical modeling technique to see the evolution of electrode morphology and correlate it directly to voltage.

Neil Dasgupta, University of Michigan assistant professor of mechanical engineering, believes the platform they have developed is fairly simple and can be used by researchers worldwide. "It can be reproduced in any lab with an optical microscope, simple electrochemical equipment, a machine shop and a $100 budget," he added in a press release.

You can see in the video below, Dasupta and his colleague in the research, Kevin Wood, describe the issue they are trying to tackle and how their research may help solve it.

What the researchers observed in their own use of the visual technique was quite interesting as well. They saw that the dendrites grow when the lithium accumulates on the surface of an electrode. However, the dendrites then shrink when the cycle is reversed and the lithium is pulled away from the surface of the electrodes. Unfortunately, after the lithium is pulled away from the surface of the electrodes, pits are left behind. These pits become breeding grounds for dendrites in the next cycle of the battery.

From these early observations, the researchers don’t expect that dendrite growth can be completely eliminated, but by better understanding how they grow it may be possible to limit the growth and thereby extend the life of lithium-metal batteries.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.